Cleaning method, method of manufacturing semiconductor device, and substrate processing apparatus

A substrate and cleaning treatment technology, applied in cleaning methods and appliances, semiconductor/solid-state device manufacturing, chemical instruments and methods, etc., can solve the problems of reduced cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

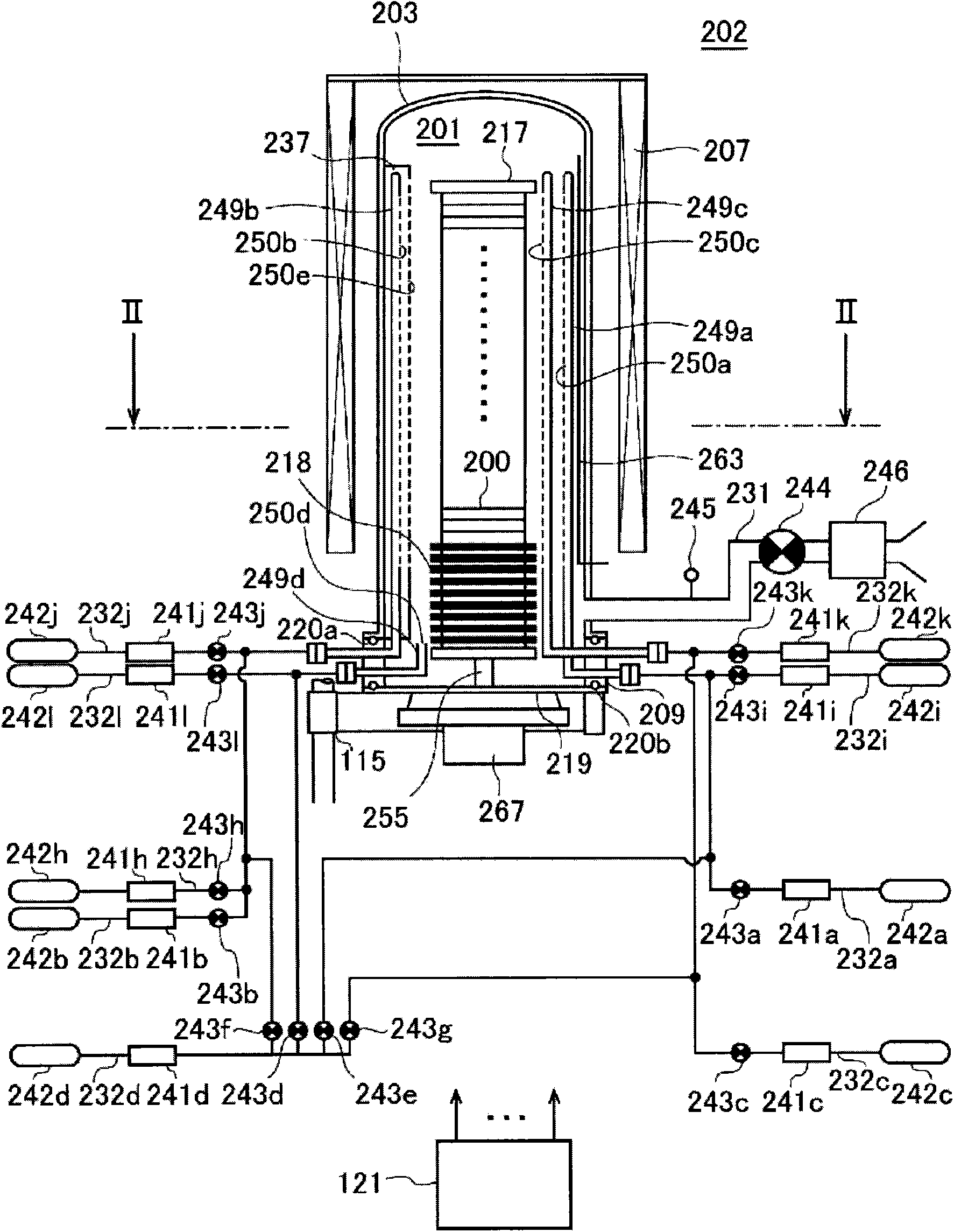

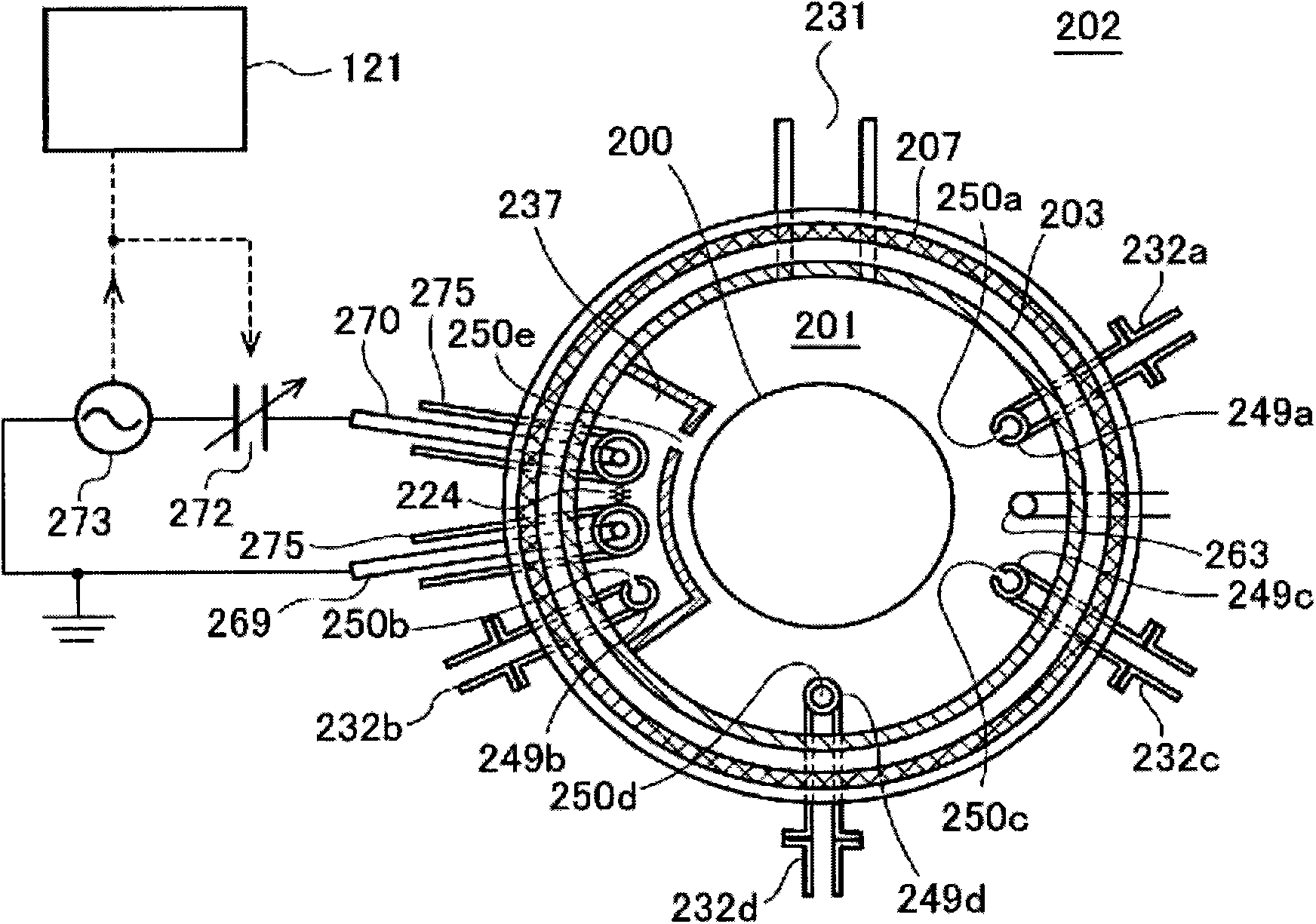

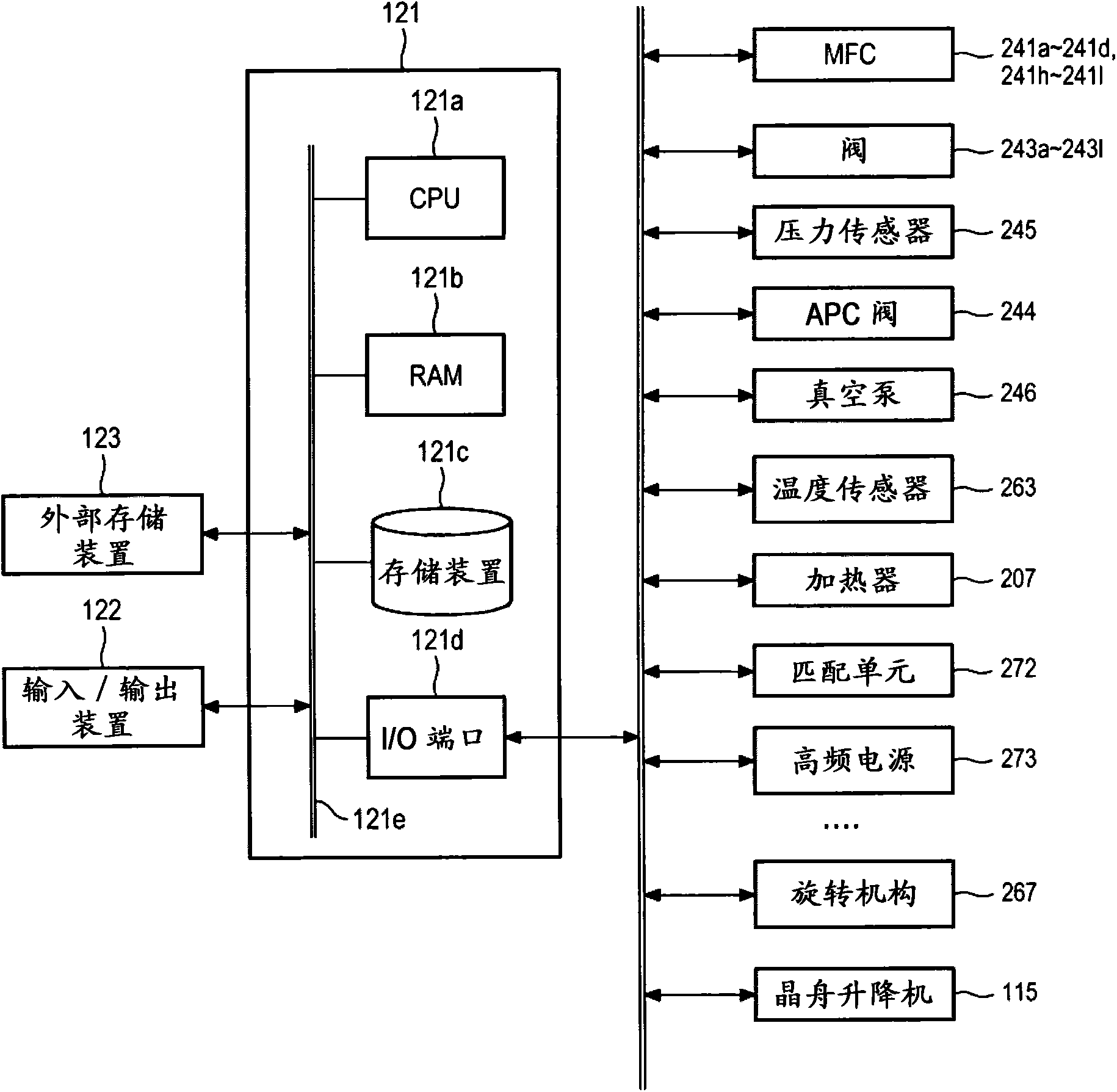

Method used

Image

Examples

other Embodiment approach

[0246] Although the embodiments of the present disclosure have been described in detail so far. However, the present disclosure is not limited to the aforementioned embodiments or modifications, and various modifications can be made without departing from the spirit of the present disclosure.

[0247] In the aforementioned embodiment or modification, an example was described in which the SiOC film was formed at a low temperature by supplying a catalytic gas together with a precursor gas or an oxidizing gas, but the configuration of the present disclosure is not limited thereto. For example, without the use of catalytic gas, O 2 A gas or the like as an oxidizing gas can be excited into a plasma state and supplied to the wafer 200 in a state in which its oxidizing ability is enhanced. But in this case, in order to prevent desorption of C from the SiOC film, low high-frequency power is required so that the oxidation reaction proceeds more smoothly.

[0248] In the foregoing emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com