Pipeline cutter

A pipe cutting machine and pipe cutting technology, applied in metal sawing equipment, metal processing machinery parts, driving devices, etc., can solve the problems of high requirements for operators, inconvenience of operators, injury of operators, etc., and eliminate potential injuries Hazardous, improved operational stability and safety, and effects of saving installation space and usable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

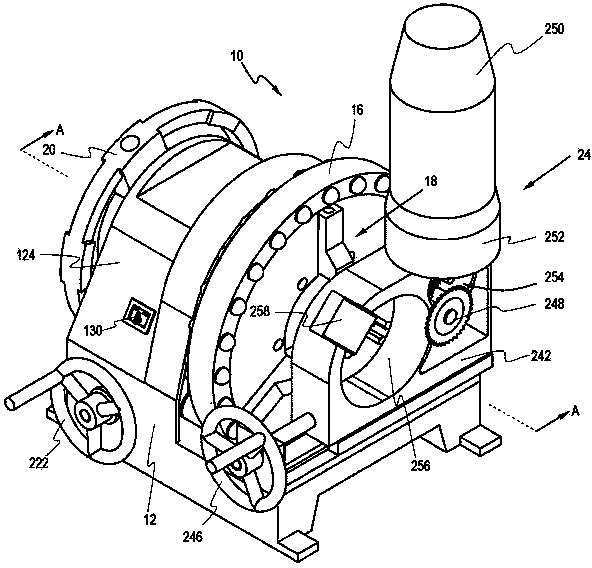

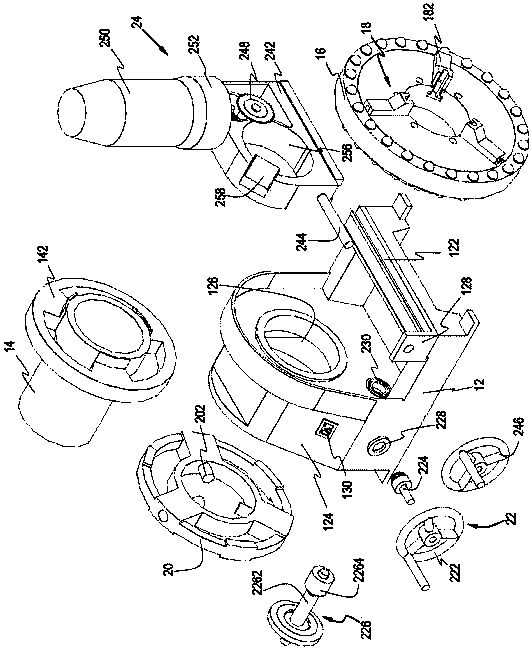

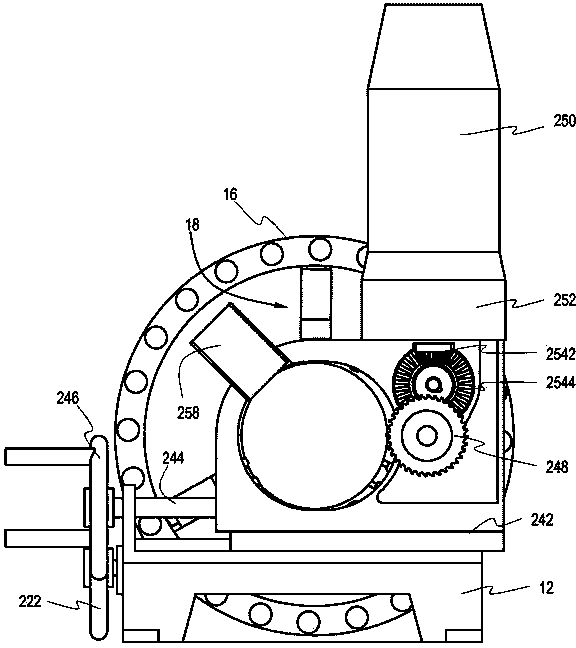

[0012] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0013] According to the present invention, there is provided a figure 1 The pipe cutter 10 is shown. figure 2 show figure 1 An exploded perspective view of the pipe cutter 10 is shown. When referring to the accompanying drawings to illustrate the pipe cutting machine 10 of the present invention, the longitudinal direction refers to the direction parallel to the axial direction of the pipe accommodating hole where the pipe to be cut is placed, that is, the The direction parallel to the axial direction of the pipe to be cut in the machine, and the transverse direction refers to the direction perpendicular to the above-mentioned longitudinal direction.

[0014] Such as figure 1 and figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com