Preparation method of optic fiber sensing ring capable of releasing internal winding stress force

A technology of sensing rings and fiber optic rings, which is applied in the field of fiber optic gyroscopes, can solve problems such as gyroscope output instability, optical fiber optical performance index decline, and damage to ring stability, so as to eliminate influences, improve temperature performance, and reduce heat dissipation. The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preparation method of the optical fiber sensing loop capable of releasing internal winding stress of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] A method for preparing an optical fiber sensing loop capable of releasing internal winding stress, comprising the following steps:

[0025] step 1

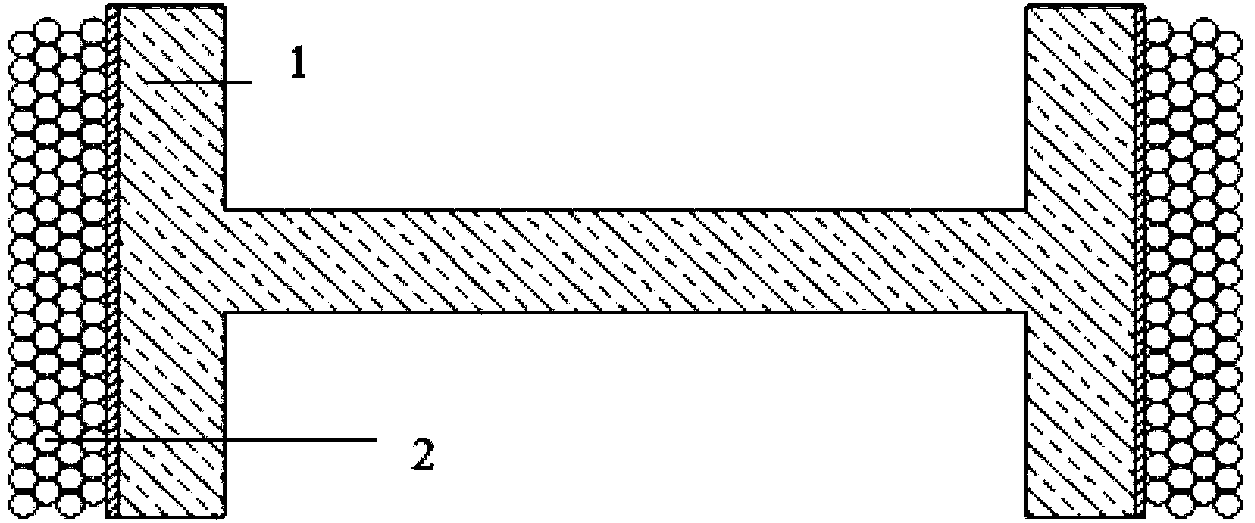

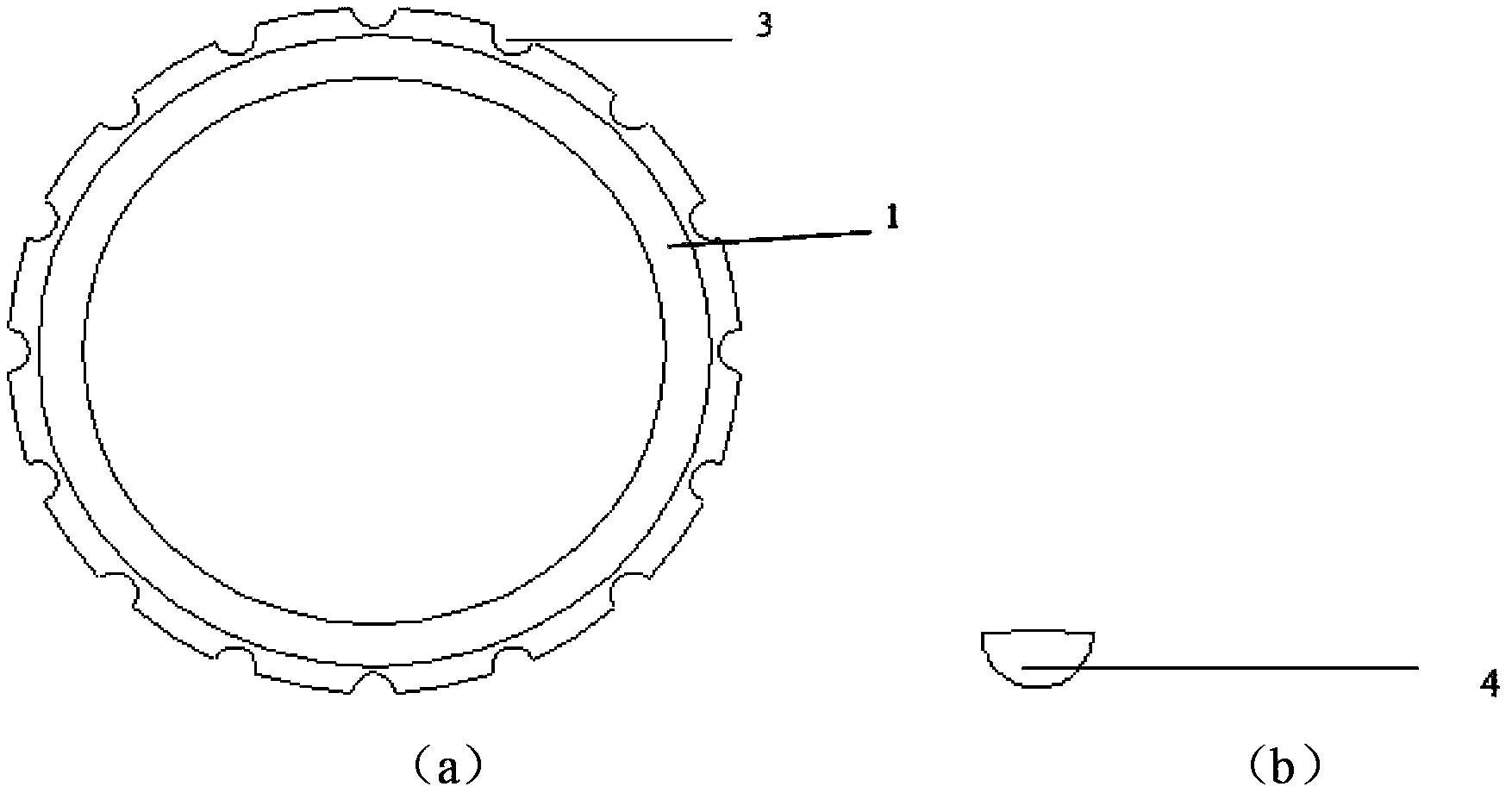

[0026] The ring frame 1 is cleaned with an organic solvent to remove attachments and pollutants on the winding surface; the semi-cylindrical body 4 is filled in the groove 3 of the ring frame 1 .

[0027] step 2

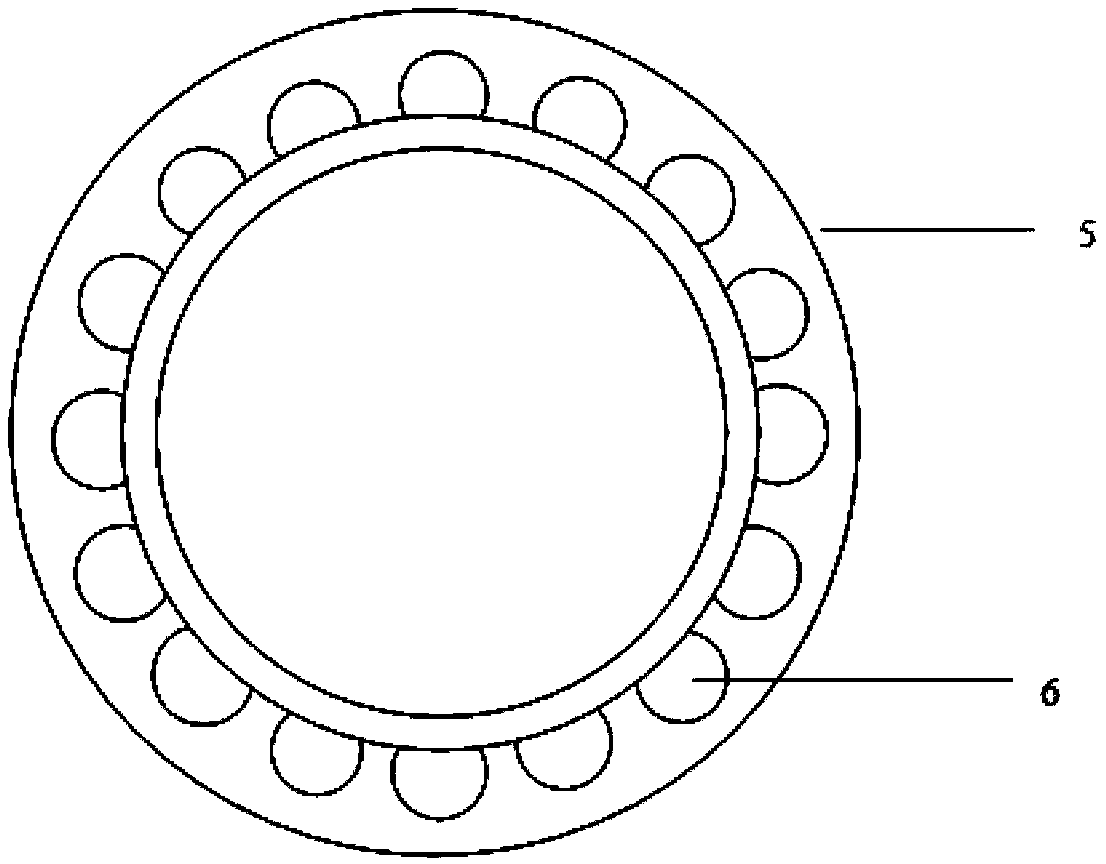

[0028] Fix the hoop frame 1 with two winding tooling 5, wherein the opening 6 of the winding tooling 5 is installed in a staggered manner with the groove 3 of the hoop frame 1, so as to prevent the half cylinder 4 filled in the groove 3 from slipping out.

[0029] step 3

[0030] Put the polarization-maintaining optical fiber 2 and the ring frame 1 into a high-temperature test box a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com