Partially colored optical element and method of manufacturing the same

A technology of optical components and parts, applied in the direction of optical components, optical components, optics, etc., can solve the problems of reducing safety advantages, and achieve the effects of saving coating procedures, avoiding error sources, and smooth transitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

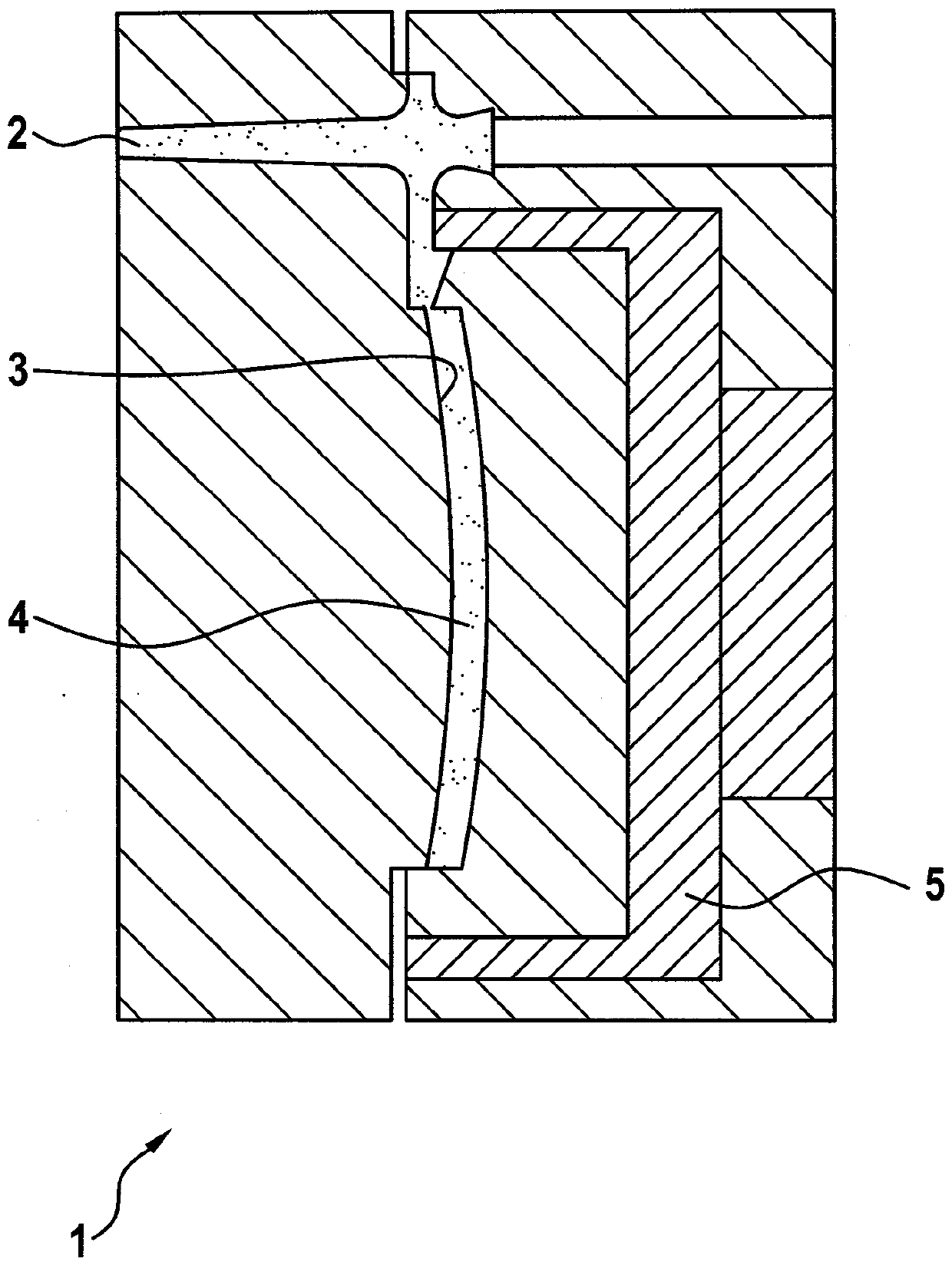

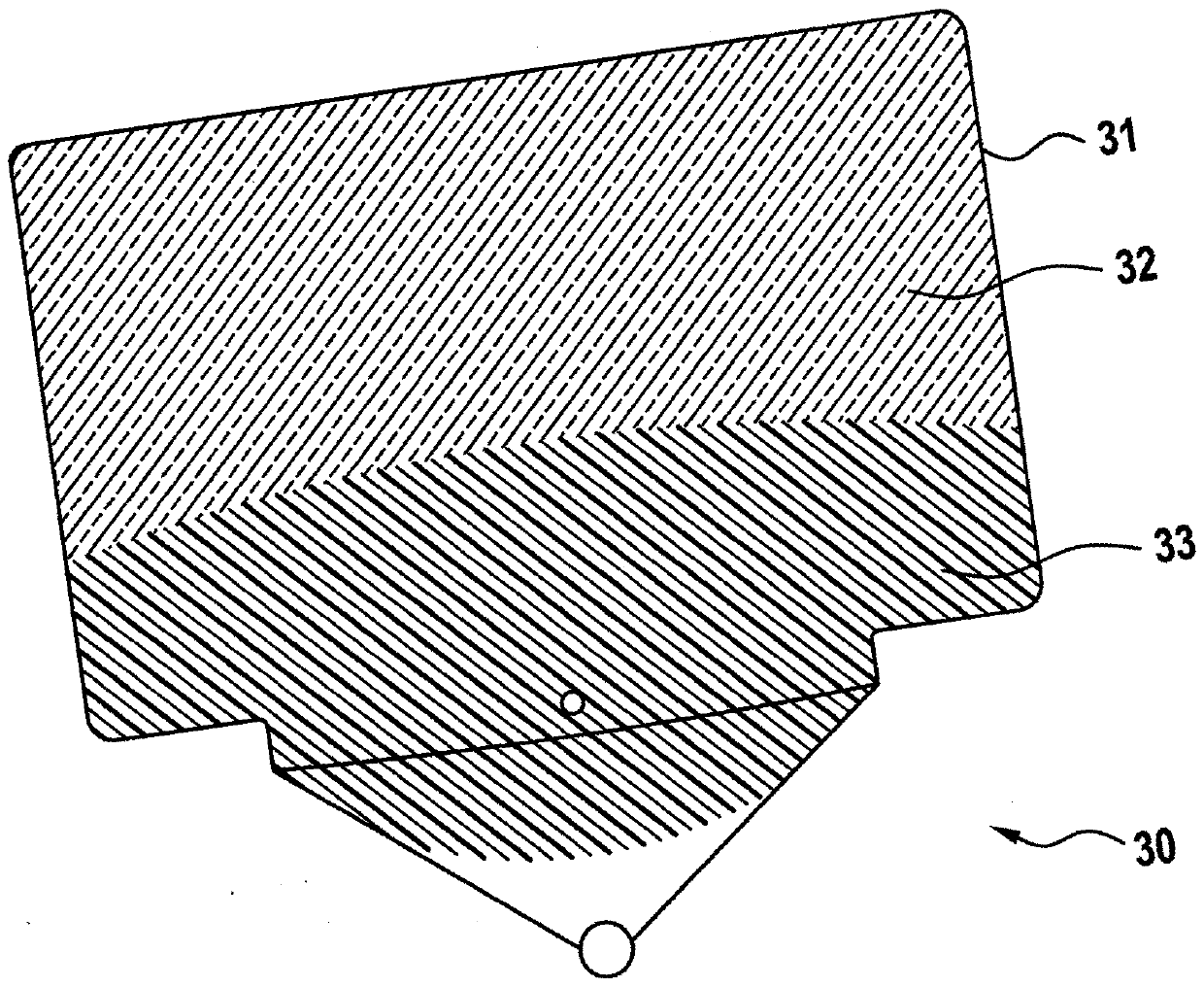

[0030] In order to produce an optical element according to the invention, such as a partially colored plastic combiner tray, it is possible, for example, to use a die-casting machine with an injection stamping tool and an adjustable press with a die-casting tool with a paint metering device . exist figure 1 In a first step shown in , a transparent molded body is produced in a known manner on the die-casting machine from, for example, the thermoplastic polycarbonate (PC) with a tool 1 , for example an injection stamping tool. In this case, the cavity 3 is first filled with a liquid plastic melt through the spout 2 of the tool 1 and the first layer 4 is then pressure-regulated formed by means of a stamping punch 5 . The stamping punch 5 can be designed, for example, in such a way that it has a stamping edge at the cut-out or sprue and in this way separates the sprue with a stamping stroke. If the first layer 4 requires an incision thicker than the stamping stroke, the molded b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com