Dry direct-seeding machine for paddy rice

A dry direct seeding and rice technology, which is applied to fertilizers and sowing equipment, agricultural machinery and implements, spades, etc., can solve the problems of the inability to guarantee the quality of dry direct seeding of rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

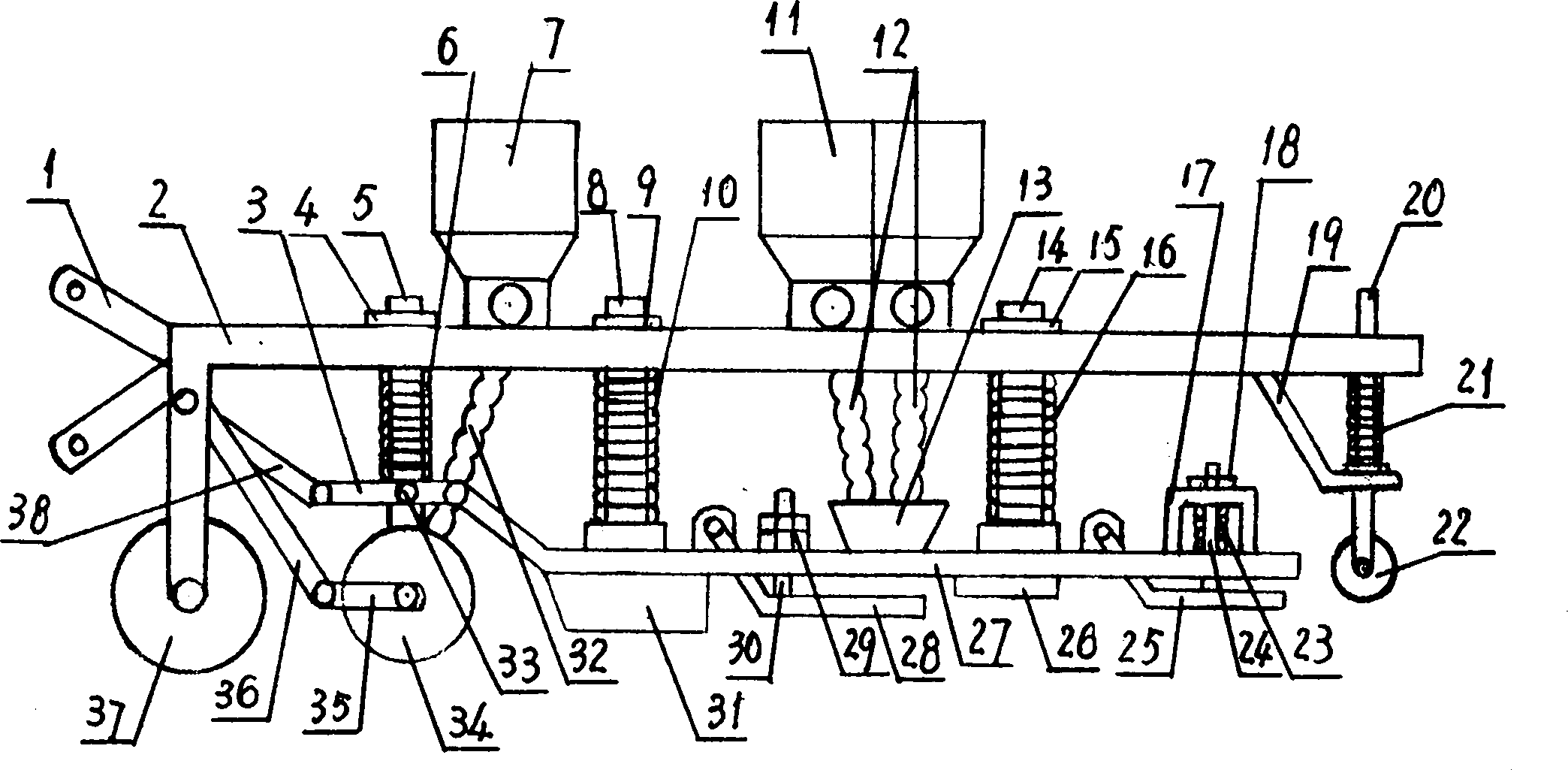

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A rice dry direct seeding machine includes a frame assembly 2 and a three-point suspension frame assembly 1 fitted on the frame assembly 2, a bottom fertilizer box 7 and a seed fertilizer box 11, which are placed on the lower part of the front side of the frame assembly 2 The rotatable installation of the rolling-type soil leveler 37, the connecting rod A38 and the connecting rod B36 are swingably hinged on the front end of the frame assembly 2, and the rocker 3 is hingedly installed on the rear end of the connecting rod A38, On the rear end of the rocking bar 3, the level mobilizer 27 is hingedly installed, on the rear end of the connecting rod B36, the swing bar 35 is hingedly installed, and the disc opener 34 is rotatably installed on the swing bar 35 ; On the lower side of the flat mobilizer 27, a ridger 31, a fertilizer ditch opener 28, a soil cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com