A kind of equipment and method for producing wonton

A wonton and equipment technology, which is applied in the field of equipment for producing wontons, can solve the problems of thick wonton noodles, affect the taste, and cannot achieve the effect of imitation by hand, and achieves a high degree of industrialization, provides production efficiency, and is conducive to large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for producing ravioli, characterized in that the steps comprise:

[0050] A, noodle supply device 1 conveys strip-shaped dough, one end of the dough is fixed by pulling device 8, and cutter 9 cuts the fixed dough into a rectangular block;

[0051] B. The stuffing device 3 pushes the stuffing sent from the stuffing device 2 vertically downwards onto the cut rectangular dough. Since the stuffing device 3 provides a downward thrust, the dough and stuffing are pushed into the lower part at the same time. In the forming device 4, the forming device 4 clamps the dough, and the dough is folded for the first time after being stressed, and the folded skin is in an upright U-shape, and the filling is at the bottom of the U-shaped structure at this time;

[0052] C, the piercing bar 6 in the molding device 4 applies a lateral thrust to the vertical side of the U-shaped dough, so that the dough forms a second fold, and the folded dough is a U-shaped lying on its side;

[...

Embodiment 2

[0056] A method for producing ravioli, characterized in that the steps comprise:

[0057] A, noodle supply device 1 conveys strip-shaped dough, one end of the dough is fixed by pulling device 8, and cutter 9 cuts the fixed dough into a rectangular block;

[0058] B. The stuffing device 3 pushes the stuffing sent from the stuffing device 2 vertically downwards onto the cut rectangular dough. Since the stuffing device 3 provides a downward thrust, the dough and stuffing are pushed into the lower part at the same time. In the forming device 4, the forming device 4 clamps the dough, and the dough is folded for the first time after being stressed, and the folded skin is in an upright U-shape, and the filling is at the bottom of the U-shaped structure at this time; the filling device 3 will When the stuffing is inserted into the dough, the position where the stuffing device 3 is inserted is located next to the center of the dough, and the folded dough is in an upright U-shape, and t...

Embodiment 3

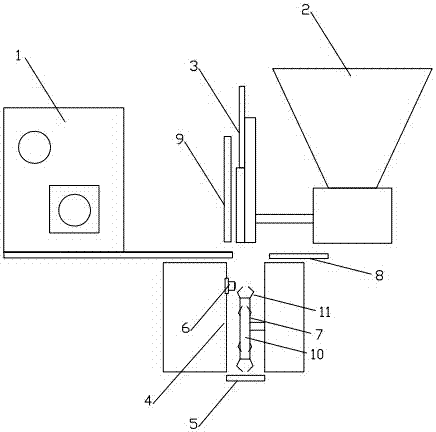

[0063] A device for producing ravioli includes a noodle supply device 1, a filling device 2, a filling device 3, a forming device 4 and a conveying device 5, the filling device 3 and the filling device that push the filling vertically downward into the dough 2 connected, the noodle supply device 1 is located on the side of the filling device 3, there is a forming device 4 below the filling device 3, and a conveying device 5 is arranged below the forming device 4; the forming device 4 includes a conveyor belt The side of the stuffed dough provides a horizontal thrust bar 6 for piercing the skin, and a rotating clamping device 7 for overlapping and pressing the two ends of the stuffed dough.

[0064] The present invention adopts a forming device 4 capable of double-folding the dough, so that the dough is less likely to be damaged during the production process of the wonton, and secondly, the appearance of the wonton folded twice is closer to the appearance of manual kneading than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com