A high-efficiency clarification method for apple juice

An apple juice, high-efficiency technology, applied in food science and other fields, can solve the problems of high cost and low light transmittance, and achieve the effect of low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

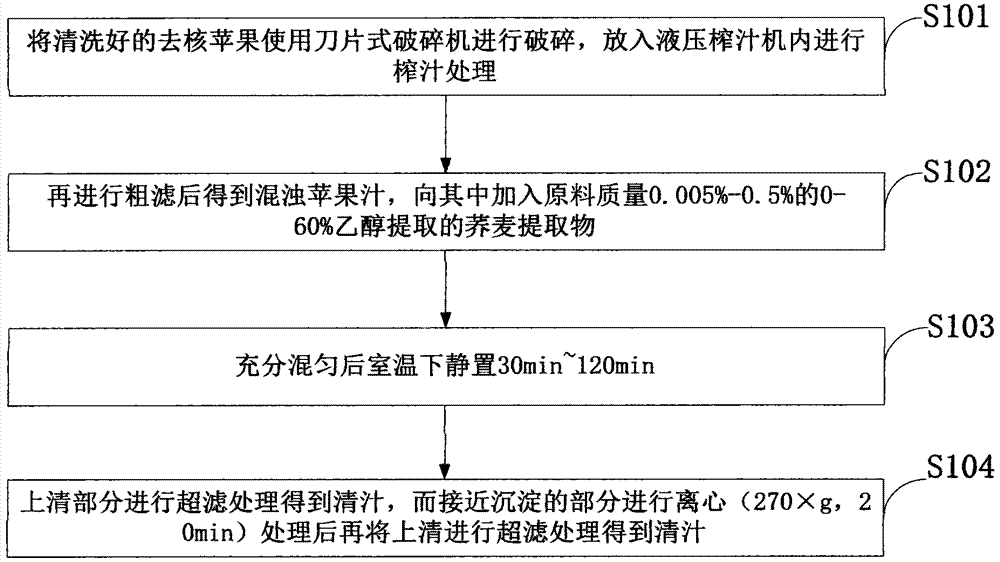

[0046] The preparation process of apple juice among the present invention:

[0047] 1 Cleaning: Rinse with clean water several times to remove surface dust and mud;

[0048] 2 Crushing: use a blade crusher to crush the cleaned apples;

[0049] 3 Juicing: Use a hydraulic juicer to squeeze the crushed apples;

[0050] 4 Filtration: filter with 100-120 mesh filter cloth to obtain turbid apple juice;

[0051] 5 Adding inhibitors: adding prepared buckwheat extracts (BEs) to the turbid apple juice, accounting for 0.005% to 0.5% of the mass of raw materials;

[0052] 6 Mixing: fully stir and mix the apple juice;

[0053] 7 Stand still: stand at room temperature for 30min to 120min;

[0054] 8 ultrafiltration: the supernatant part is subjected to ultrafiltration treatment to obtain clear juice;

[0055] 9. Centrifugation: centrifuge the part close to the precipitate at 270×g for 20 minutes, and then perform ultrafiltration on the supernatant to obtain clear juice.

[0056] The e...

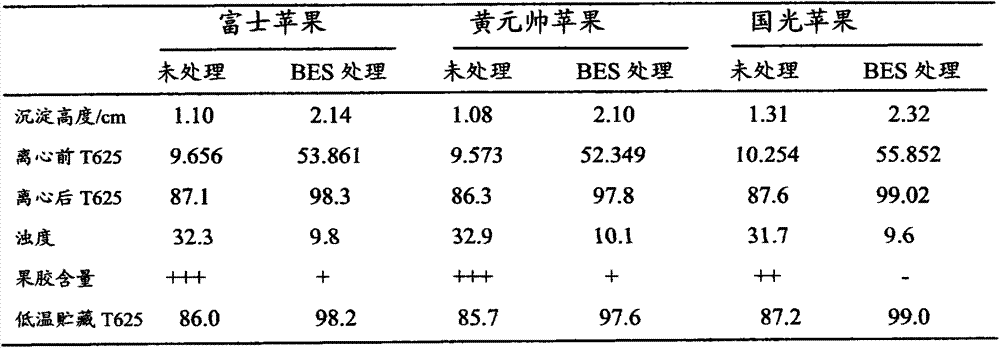

Embodiment 1

[0058] Crush 1000g of cleaned cored Fuji apples with a blade crusher, put them into a hydraulic juicer for juice extraction, filter them with a 100-mesh filter cloth to obtain turbid apple juice, and add 0.5g of raw material quality to it. Buckwheat extracts (BEs) extracted with 60% ethanol, fully mixed and left at room temperature for 30 minutes, to detect the precipitation height of the fruit juice at different times, then take out some samples for index detection, and ultrafilter the supernatant of the remaining samples The clear juice is obtained after processing, and the part close to the sediment is centrifuged (270×g, 20min) and then the supernatant is subjected to ultrafiltration to obtain the clear juice. After the index detection, the sample is stored at low temperature before detection, and the buckwheat extract is replaced by water as a blank control;

Embodiment 2

[0060] Crush 1000g of the cleaned pitted yellow Marshal apples with a blade crusher, put them into a hydraulic juicer for juice extraction, filter them with a 120-mesh filter cloth to obtain turbid apple juice, and add 2.5g of raw materials to it The buckwheat extract (BEs) extracted with 30% ethanol was fully mixed and allowed to stand at room temperature for 60 minutes to detect the sedimentation height of the juice, and then some samples were taken out for index detection, and the supernatant of the remaining samples was processed by ultrafiltration to obtain clear juice, while The part close to the precipitation was centrifuged (270×g, 20min) and then the supernatant was subjected to ultrafiltration to obtain the clear juice. After the indicator was detected, the sample was stored at low temperature before detection, and water was used instead of buckwheat extract as a blank control;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com