Activated carbon fiber honeycomb filter and production method thereof

A technology of activated carbon fiber and production method, which is applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems that activated carbon cannot be used twice, affect the air purification effect, and cannot be regenerated, and achieves easy regeneration and wind resistance. Small, strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A kind of production method of active carbon fiber honeycomb filter screen, comprises the following steps:

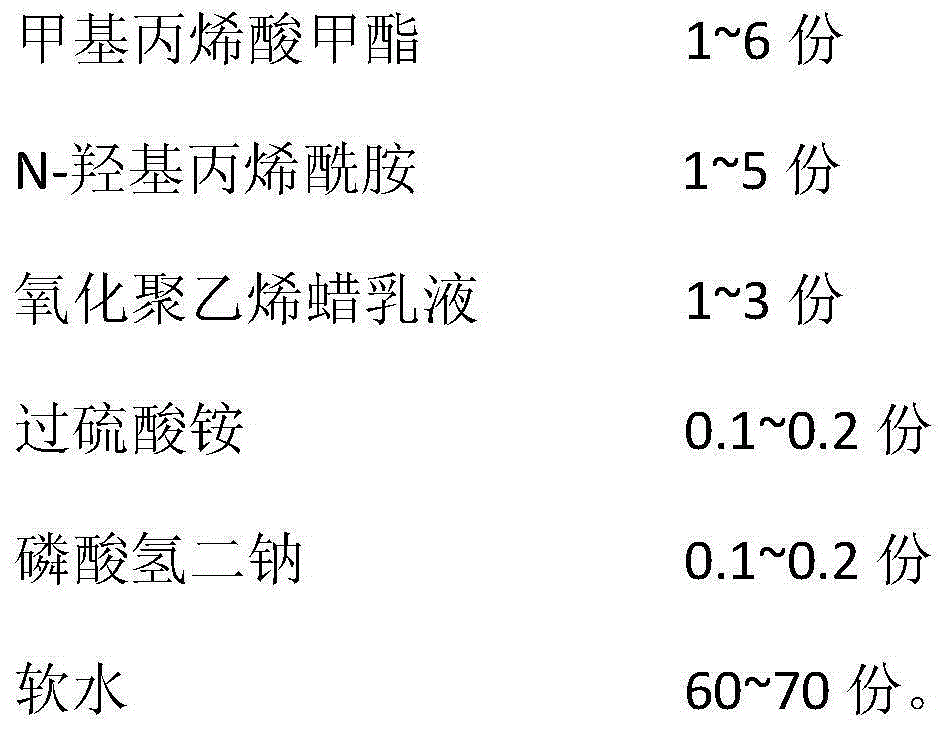

[0024] (1) Activated carbon fibers are impregnated or sprayed with a strengthening treatment agent (get wet), and then dried; the strengthening treatment agent is composed of the following components by weight:

[0025]

[0026]

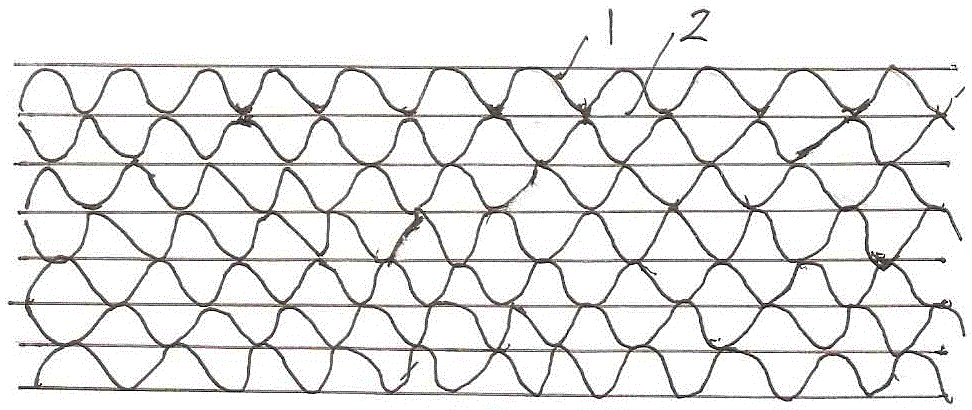

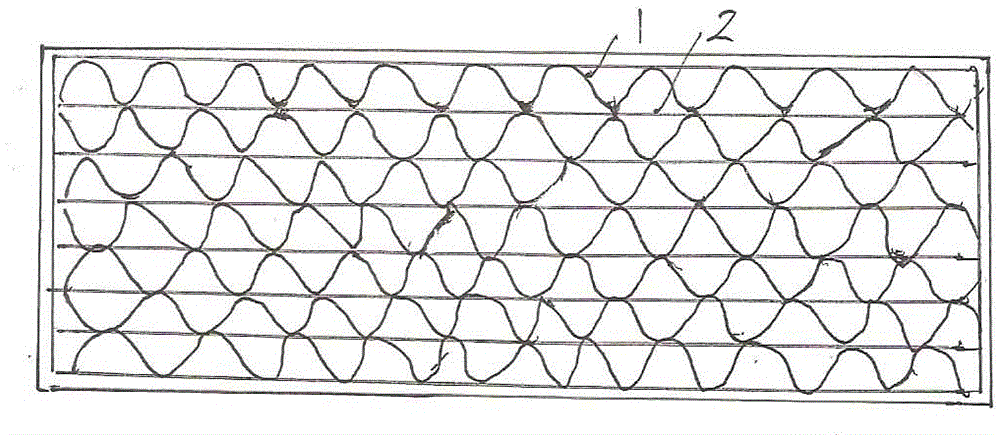

[0027] (2) Make activated carbon fiber into corrugated board 1 (with U-shaped or V-shaped wave structure) and flat board 2 with a shaping device, and laminate the corrugated board and flat board through the glue layer on the end surface of the corrugated board, and repeat the lamination several times to form a honeycomb Shaped composite, and can be cut into products of different specifications with a band saw machine;

[0028] (3) The honeycomb composite body is subjected to the treatment of removing the strengthening treatment agent; the product is obtained.

[0029] The setting temperature of the setting equipment is 160-180°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com