A method for grinding and polishing platinum vessels using an automatic platinum vessel grinding and polishing machine

A technology for grinding and polishing machines and utensils, which is applied in the field of polishing and polishing, and platinum utensils, so as to achieve the effect of saving expensive costs, improving work efficiency, polishing effect and high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

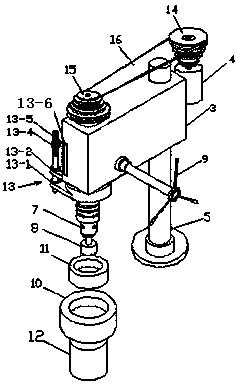

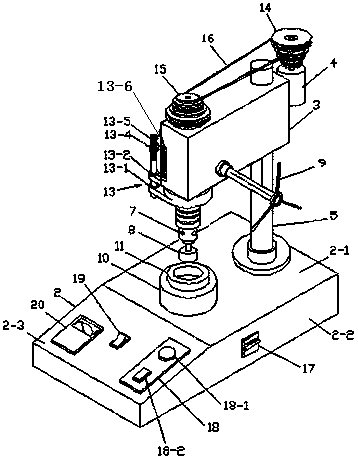

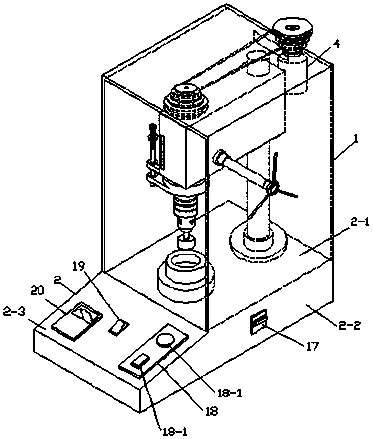

[0051] Such as Figure 1 to Figure 6 As shown, a method for grinding and polishing platinum utensils by using an automatic platinum utensil grinding and polishing machine. Grinding and polishing machine main shaft 6, lock head 7, polishing head 8, lifting joystick 9, fixed sleeve 10, crucible fixed sleeve 11, fixed sleeve motor 12, limiter 13, driving wheel 14, driven wheel 15 and belt 16;

[0052] The protective cover 1 is composed of two side plates, a top plate and a rear plate, and the protective cover 1 is fixedly connected with the workbench 2;

[0053] The workbench 2 includes an upper plate 2-1, a right side plate 2-2 and a control panel 2-3; the upper plate 2-1 serves as a base for fixing the fixed shaft 5 of the grinding and polishing machine, and the fixed shaft 5 of the grinding and polishing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com