Pressure pipe with formed connecting head

A pressure pipe and pressure technology, which is applied in the direction of pipes/pipe joints/pipe fittings, connections that use fluid pressure for packing seals, pipes, etc., can solve cumbersome problems, reduce the formation of upset forging wrinkles, and improve the use of strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

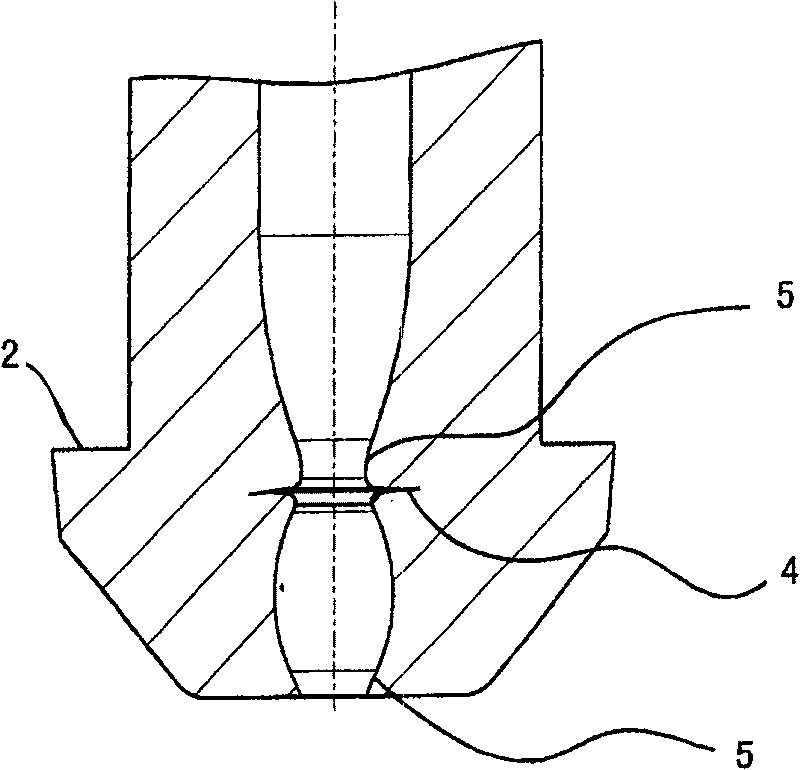

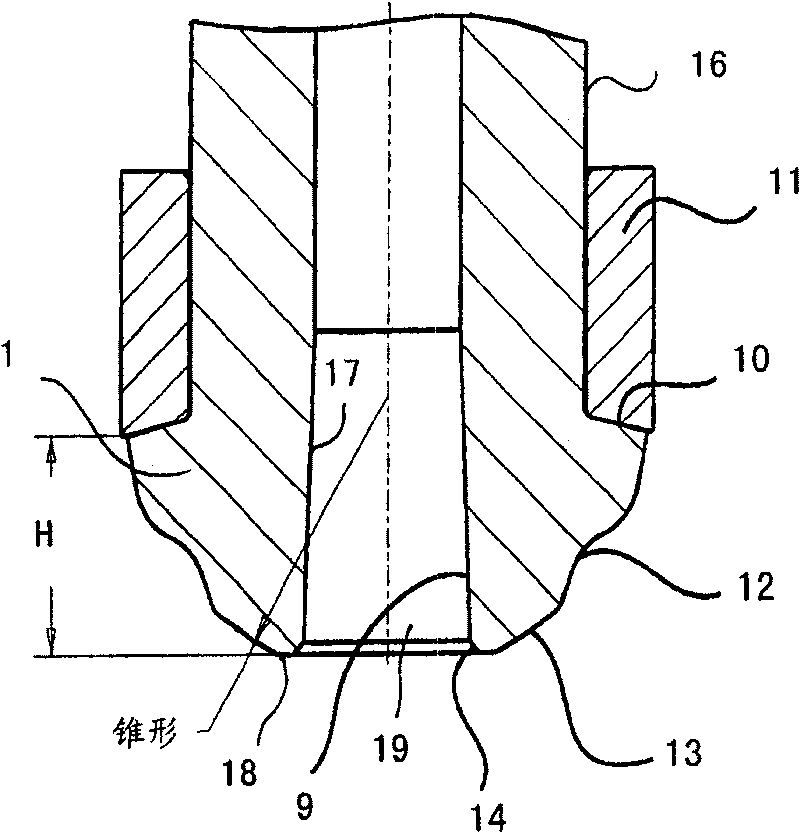

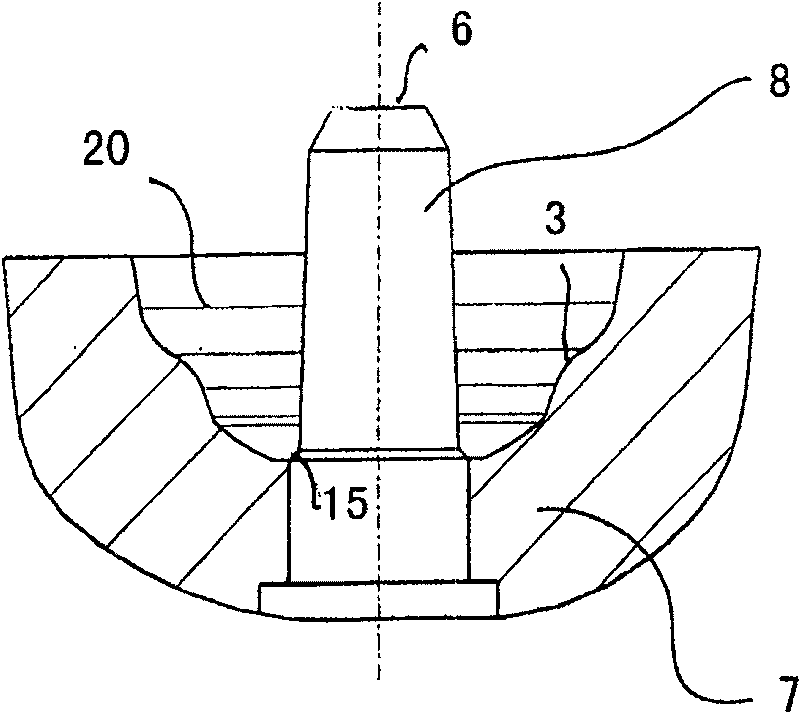

[0028] figure 2The pipe end of the fuel injection pipe with connection 1 and pipe 16 is shown. The beveled pressure shoulder 10 bears on a pressure ring 11 which is required for tightening, for example using a union nut (not shown). The envelope surface of the frusto-conical joint has both a concave arc 12 and a sealing surface 13 . The sealing surface 13 serves to seal the pressure pipe against a counterpart from the injection system (not shown). An inner cone 9 is formed in the region of the joint on the inner surface 17 of the pressure tube. The inner cone 9 forms a tube opening 19 on the top surface 18 . The pressure shoulder 10 forms an angle of greater than 90° with the outer surface of the pressure tube 16 . This angle is preferably between 100° and 110°. The loading of the pressure ring 11 is favorable in this angular range. The height H of the joint also has an effect on the formation of upset folds and should lie in the range of 0.5 to 1.0 times the outer diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com