Straight-edge machine suitable for bamboo and wood products

A technology for edge straightening machines and products, which is used in slotting machines, manufacturing tools, and mortising machines, etc. It can solve the problems of the influence of materials and cutting devices, the influence of the working environment, and the too deep grooves, so as to achieve firm positioning. , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

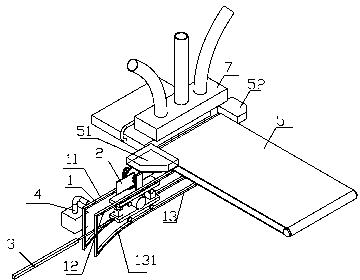

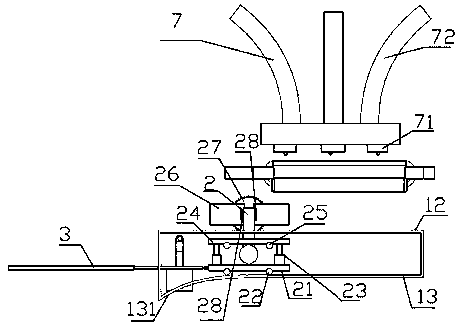

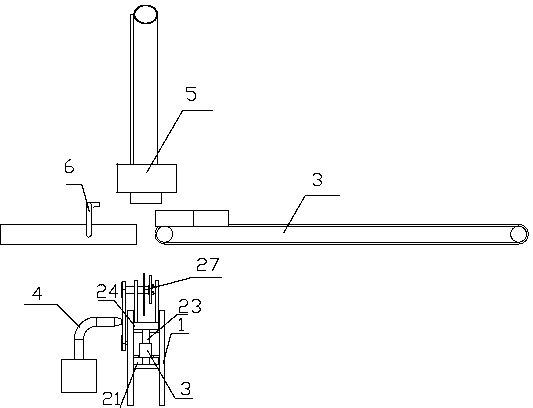

[0036] Example 1, such as figure 1 — Figure 5 Shown: a straight edge machine suitable for bamboo and wood products, including a frame 1, a conveyor table 5 for transporting bamboo and wood products, and a machine that can move on the frame 1 and cut bamboo and wood products on the conveyor table 5 Cutting device 2, this edge straightening machine also comprises the oil spraying device 6 that is used to spray lubricating oil and lubricating cutting device 2 and spraying position is on the side of cutting device 2 far away from bamboo and wood products, and this edge straightening machine also comprises can promote cutting device 2 in Transversal pusher 3 sliding on rail system 11. The frame 1 is provided with a track system 11 for the sliding of the cutting device 2, the track system 11 comprises an upper track 12 and a lower track 13 arranged below the upper track 11, the cutting device 2 comprises a base 21, is located on the base 21 and on the lower track 12 Roller one 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com