New garbage treatment method

A technology of garbage disposal and a new method, which is applied in the field of sanitation, can solve the problems of secondary pollution of the environment, garbage is easily thrown out from the dislocation port between the container and the loading equipment outlet, and the docking of the container and the loading equipment is not in place, so as to prevent Unsafe accidents and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

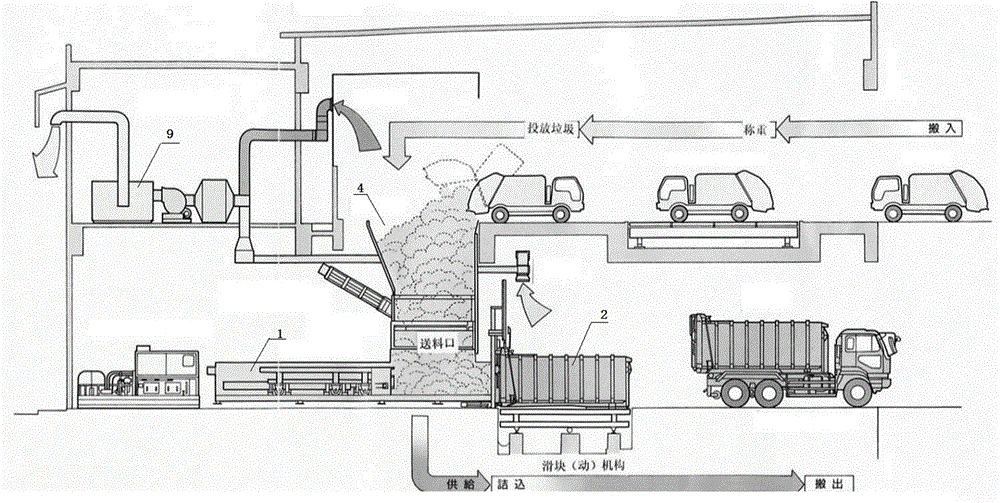

[0030] Such as image 3 It is the waste treatment process flow of the waste transfer station.

[0031] A new method for garbage disposal is characterized in that it comprises the steps of:

[0032] (1) Transport the garbage collected by the garbage collection vehicle to the garbage transfer station, and weigh the collected garbage when entering the station;

[0033] (2) Pour the weighed garbage into the receiving trough, and remove dust and deodorize the garbage poured into the receiving trough; the method of dust removal and deodorization is to use a negative pressure fan to remove dust, deodorize, and spray dust. The sewage formed in the receiving tank by spraying is discharged.

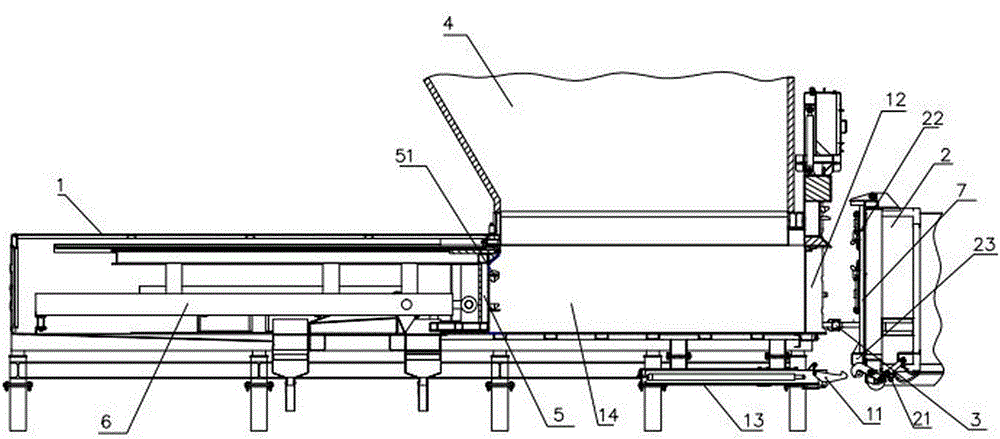

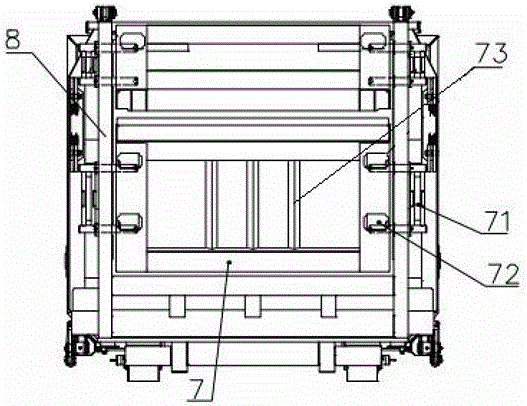

[0034] (3) Move the container body of the transshipment garbage to the loading equipment, so that the push plate on the loading equipment and the sealing plate on the container are butted together to form a composite push head;

[0035] In this step, moving the container body of the transshipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com