Inkjet printing method and device, and manufacturing method of display substrate

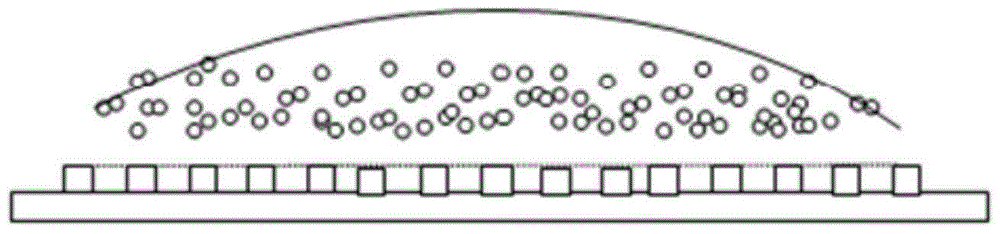

An inkjet printing equipment and display substrate technology, which is applied in printing devices, printing, semiconductor/solid-state device manufacturing, etc., can solve the problems of uneven film formation in the display area and different atmosphere concentrations, and achieve uniform and uniform film thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

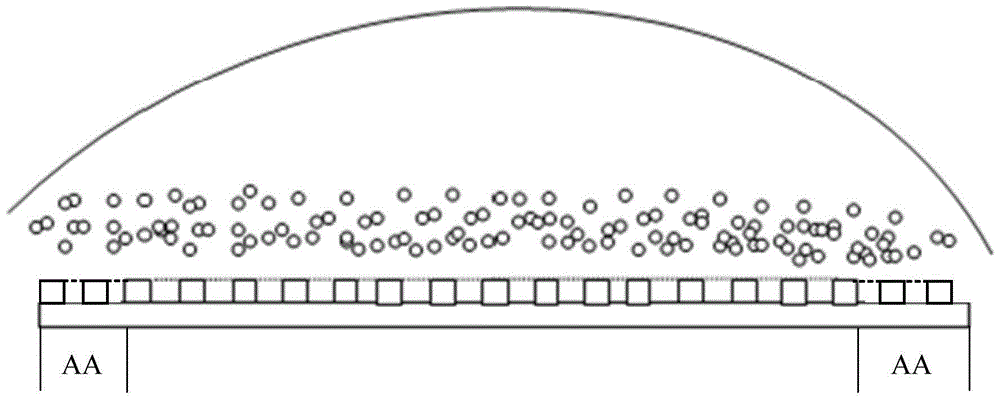

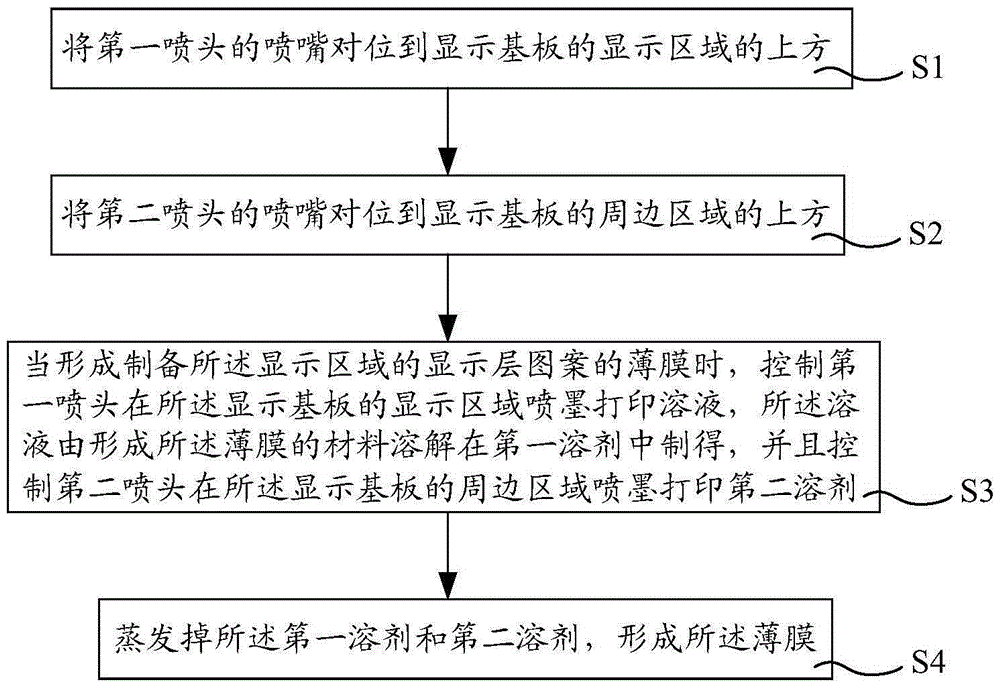

[0063] An embodiment of the present invention also provides a method for manufacturing a display substrate, the method includes the step of forming a thin film for preparing a display layer pattern in the display area on the display substrate, and using the inkjet printing method in Embodiment 1 to print on the display A thin film is formed on the substrate.

[0064] The thickness of the thin film formed by the inkjet printing method is uniform, which effectively improves the quality of the display substrate. At the same time, because the second solvent is used to print the peripheral area in the present invention, the peripheral area can be the area where the leads are originally arranged; in addition, since the second solvent is used to print the peripheral area in the present invention, the entire display substrate can In the case that the concentration of the atmosphere above is roughly the same, the size of the peripheral area can be much smaller than the printing area in...

Embodiment 3

[0067] Based on the same inventive concept, an embodiment of the present invention also provides an inkjet printing device for forming a thin film on a display substrate.

[0068] combine Figure 4 and Figure 6 As shown, the inkjet printing equipment includes:

[0069] The first nozzle 1 and the second nozzle 2;

[0070] The first alignment device 10 is used to align the nozzle 11 of the first shower head 1 above the display area BB of the display substrate 3;

[0071] The second alignment device 20 is used to align the nozzle 21 of the second shower head 2 above the peripheral area CC of the display substrate 3;

[0072] The control device 30 is used to control the first spray head 1 to ink-jet print a solution in the display area BB of the display substrate 3 when forming a thin film for preparing the display layer pattern of the display area CC. The solution is dissolved by the material forming the thin film. Prepared in a solvent, and control the second spray head 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com