A kind of oil, mud, water separation device

A separation device and separation tank technology, applied in the field of mud, water separation device and oily mud oil, can solve the problems of large pollution of the environment, waste of water resources, low liquid temperature, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

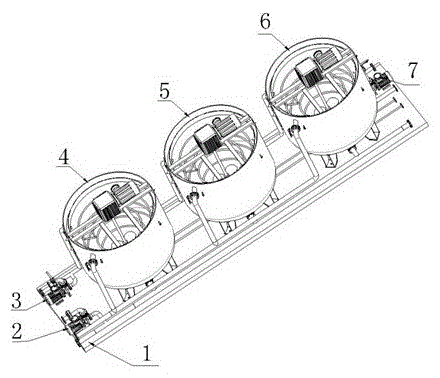

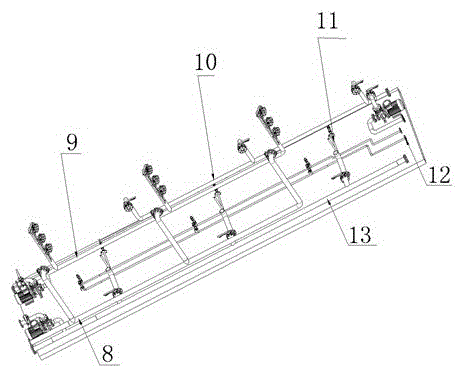

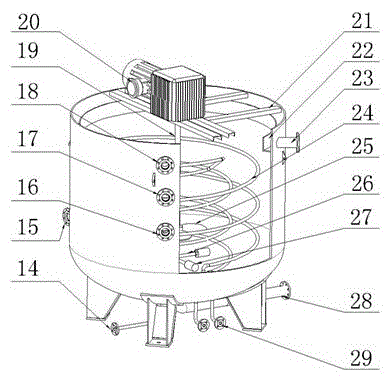

[0025] like Figure 1-9 As shown, an oil, mud and water separation device is characterized in that it includes a base 1, a separation tank, a connecting manifold, a mud discharge pump 2, a water collection pump 3 and a mud lift pump 7, and the base 1 is arranged on the The lower part of the separation device, the connecting manifold mainly includes an oil collection manifold 8, a water collection manifold 9, a liquid inlet manifold 10, an air flotation manifold 11, a heating manifold 12, and a mud discharge manifold 13. The separation Pool includes 1 # Separation pool 4, 2 # Separation pool 5 and 3 # Separation pool 6, and each separation pool is provided with pool steam air flotation nozzle 14, pool body liquid inlet nozzle 15, pool body water outlet nozzle, stirring shaft 19, agitator 20, agitator support 21, oil collection tank 22 , tank body oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com