Treatment method of waste emulsion

A waste emulsion and treatment method technology, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high price, complex and bulky air flotation equipment, and low flux of ultrafiltration membrane , to achieve the effect of reducing infrastructure costs and improving demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

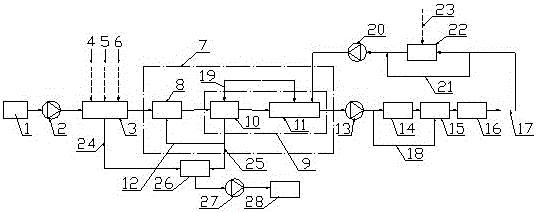

[0037] Example 1: In the physical and chemical workshop of a hazardous wastewater treatment center in Wuxi, the waste emulsion comes from various machinery factories, steel factories, and laboratories, and contains a large amount of organic oil and surfactant, as well as a small amount of organic matter. The waste liquid is treated by the method and device of the present invention, the treatment capacity is 7500t / y (25.0t / d), and the oil content in the effluent 17 after treatment is 20~50mg / L, reaching the "Comprehensive Wastewater Discharge Standard" GB8978- In 1996, the first category of water quality requirements, the solid waste treated by the sludge treatment device was sent to the hazardous waste disposal center for further treatment.

Embodiment 2

[0038] Example 2: The waste emulsion from the drawing workshop of a steel rope factory in Jiangyin has a COD as high as 30,000~50,000mg / L. The waste liquid is treated by the method and device of the present invention, and the processing capacity is 20.0t / d. The whole system Stable operation for 6 months, the oil content in the effluent 17 water quality is less than 10mg / L, meeting the first-class water quality requirements of the "Integrated Wastewater Discharge Standard" GB8978-1996, and the solid waste treated by the sludge treatment device is sent to hazardous waste disposal center for further processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com