High-alumina slag system for blast furnace smelting

A blast furnace smelting and high-aluminum slag technology, which is applied in the field of iron and steel metallurgy and ironmaking, can solve the problems of increased fuel ratio, large slag amount, and comprehensive smelting cost in blast furnace smelting, and achieves the effect of increasing the utilization ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

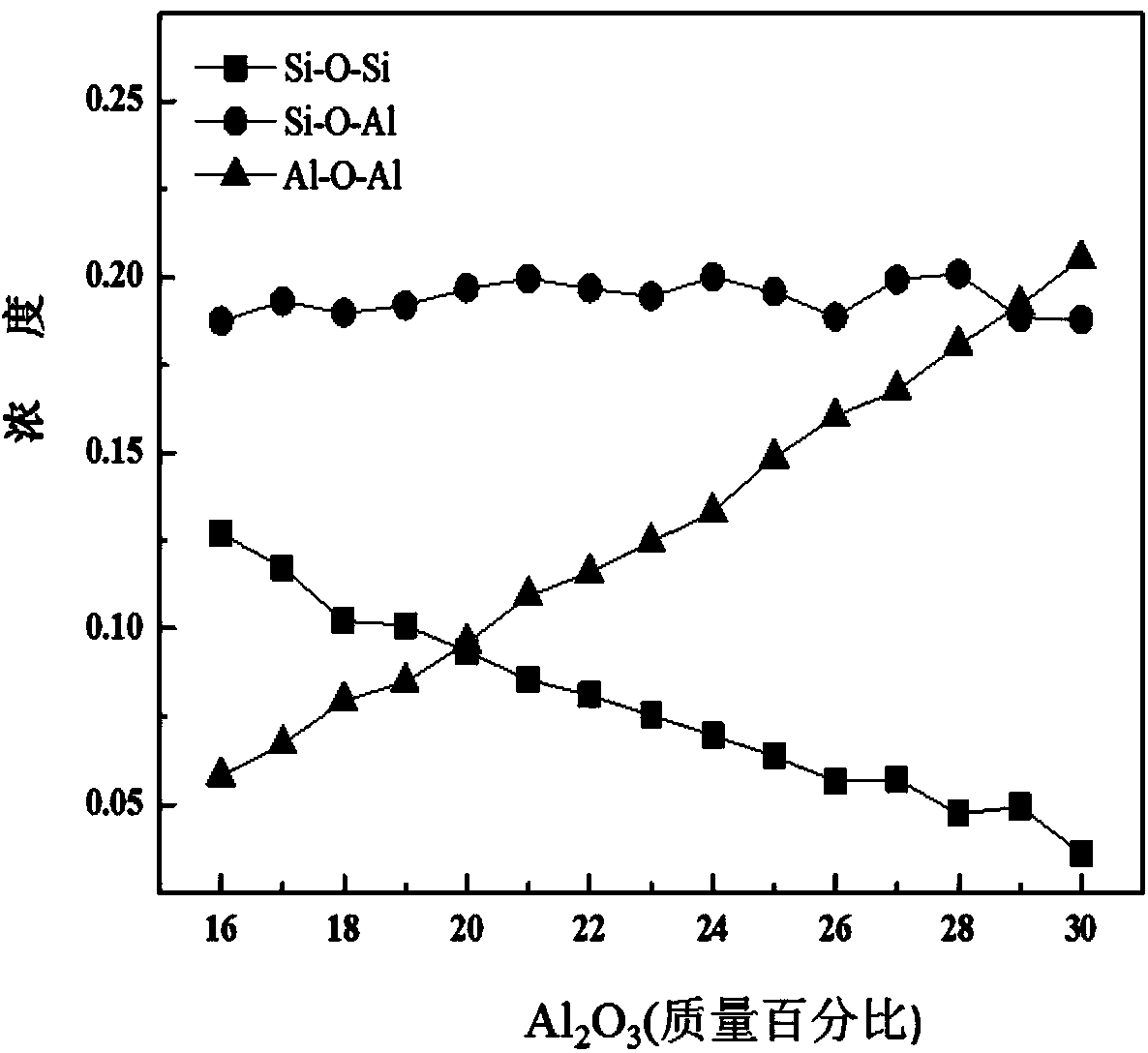

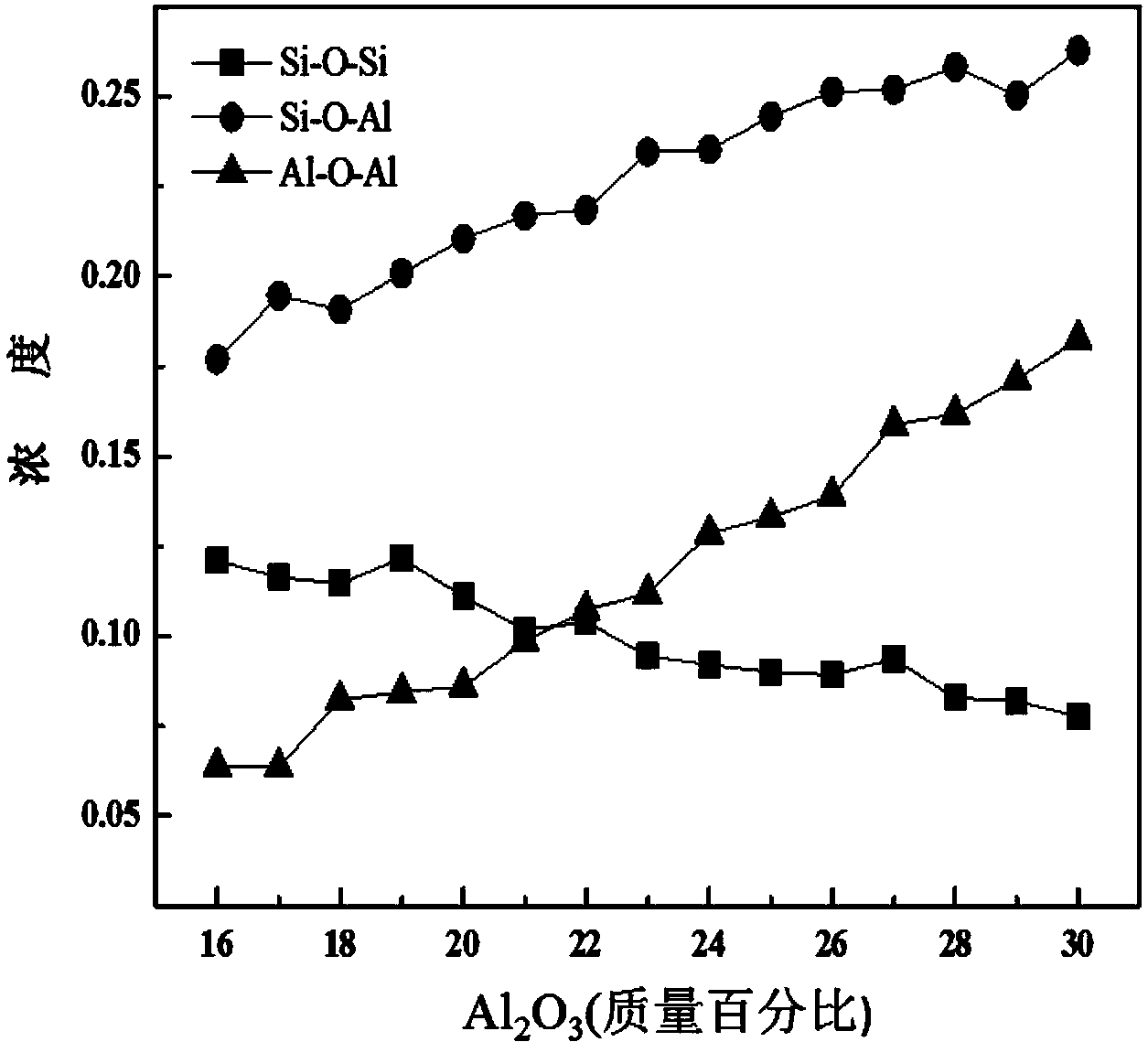

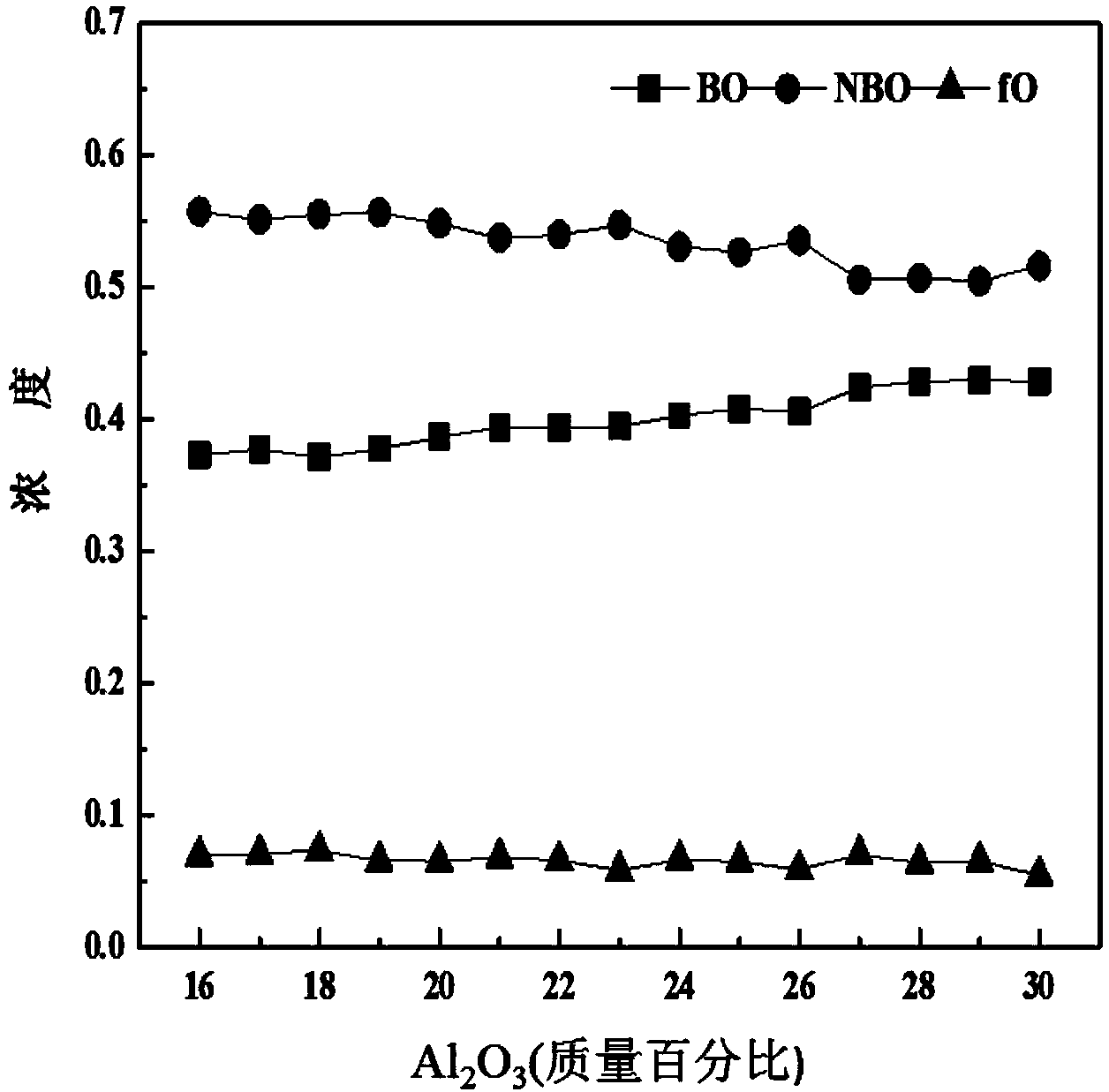

[0031] Using the same blast furnace conditions, during the normal smelting of the blast furnace 2 o 3 Generation of SiO 2 "High aluminum slag system (see Table 1) and increasing Al while maintaining the traditional binary alkalinity 2 o 3 Carry out experiment at the slag system (seeing table 2) of different percentages, measure the viscosity under different temperatures, draw temperature-viscosity figure, respectively as Figure 5 and Figure 6 shown, from Figure 5 It can be seen that, with the Al in the slag 2 o 3 As the content increases, the viscosity of the slag in the high temperature zone is basically the same as that of the normal production blast furnace. From Figure 6 It can be seen that in the slag Al 2 o 3 When 2 o 3 = 24% when the viscosity-temperature curve appears an inflection point, 24%2 o 3 In the range of 2 o 3 An increase in the content will cause the viscosity of the slag to be too high and make the operation of the blast furnace difficult, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com