Rail exchanging work vehicle for railway

A technology for working vehicles and railways, applied in the directions of roads, tracks, laying tracks, etc., can solve problems such as easy tipping of working trolleys, and achieve the effects of low cost, simple structure of working devices, and avoidance of tipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

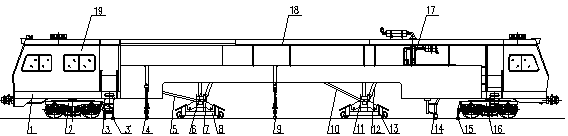

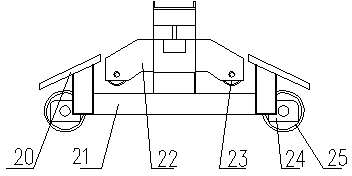

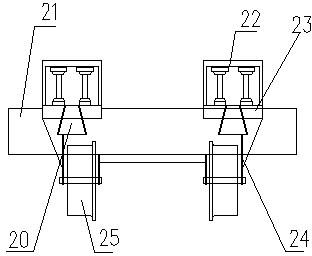

[0022] In the present invention figure 1 , figure 2 , image 3 , Figure 4 In the embodiment of the present invention, a power system 17, a shed 18 and a driver's cab 19 are installed on the vehicle frame 1, and a console, a vehicle control and a video monitoring system are arranged inside the cab 19, the engine provides power for the whole vehicle, and the console and The video monitoring system is used for vehicle running and monitoring; the first bogie 2 and the second bogie 16 are assembled from the bogie frame, wheel set, axle gearbox and hydraulic motor respectively, and the first bogie 2 is installed on the vehicle frame 1 The bottom front frame, the second rear bogie 16 is installed on the rear end frame at the bottom of the frame 1, the second bogie 16 is equipped with a rail guard 15, and the rail guard 15 is used to prevent the bogie 16 from going off-line and falling off the track; . A new rail clamp 3 and an old rail clamp 3' are installed at the rear of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com