Fast unclamping device realizing oil well drill clamping object directional explosion impact failure separation

A technology of object orientation and impact destruction, which is applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of increased construction cost, difficult to handle, prolonged time, etc., and achieves convenient construction technology, short operation time and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

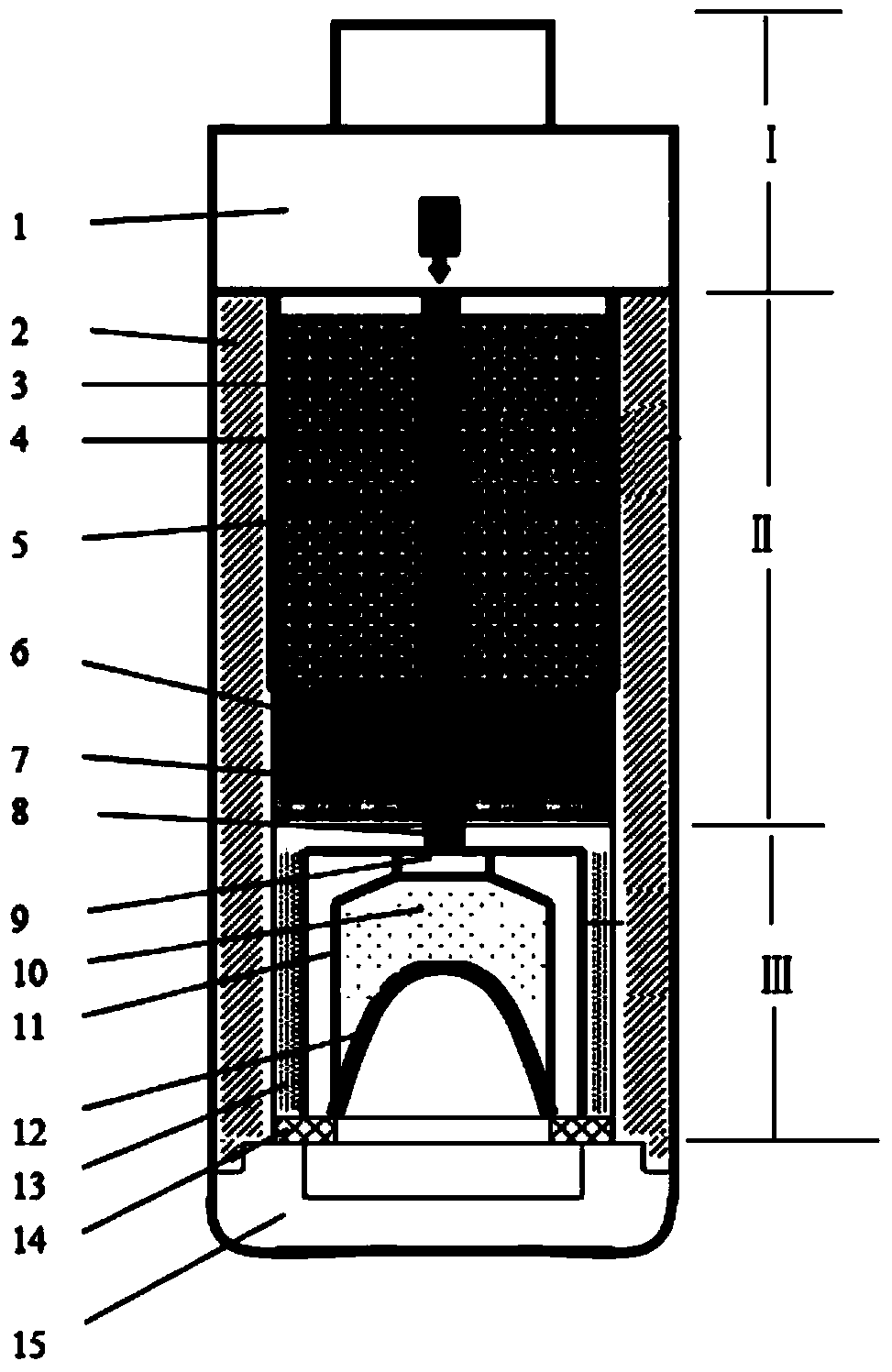

[0027] The present invention was successfully applied in the test and application process of a certain deep horizontal well stuck in Zhongyuan Oilfield, and achieved obvious effects. The drilling design of this well is composed of multi-stage casing cementing, and the vertical well section adopts 7〞, 5 1 / 2 "Casing completion (casing has been installed) is drilling into the horizontal section. During the drilling process, the three-cone bit was accidentally dumped and stuck in the vertical wellbore when the bit was replaced. The stuck bit could not go through and was worn out It can’t be washed off, and it takes more than a month to overhaul before and after, and the problem can’t be solved by various methods. According to the structure and state analysis of the stuck drill object, we finally designed the energy-gathering directional large-hole crushing device through many experiments and researches. The transmission process was applied in the unblocking test, and the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com