Soil cabin structure of shield machine

A technology of shield machine and soil tank, which is applied to earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as affecting the construction quality and progress of the project, easily forming mud cakes, affecting the discharge of slag, etc., and achieves easy installation. , the effect of high work efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

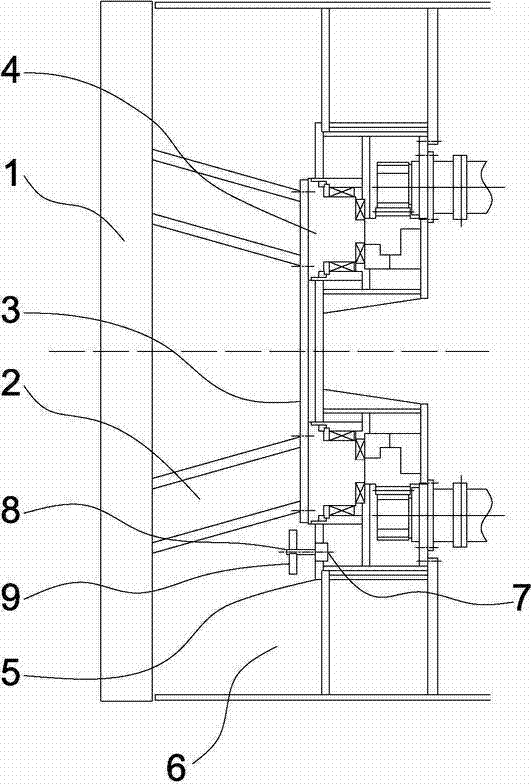

[0010] Such as figure 1 As shown, the soil cabin structure of a shield machine of the present invention includes a cutter head 1, a connecting arm 2, and a connecting flange 3. The cutter head 1 and the connecting flange 3 are disc-shaped, and the cutter head 1 Welded together with the connecting flange 2 through the connecting arm 2, the connecting flange 3 is fixedly connected to the force transmission ring 4, the outer periphery of the force transmission ring 4 is a bulkhead 5, and the bulkhead 5 and the cutter head 1 The space between forms the soil cabin 6, and the lower end of the bulkhead 5 is fixedly installed with a driving motor 7 at an appropriate position, and the side of the driving motor 7 facing the soil cabin 5 is connected with a drive shaft 8. A stirring wing 9 is fixed in the circumferential direction.

[0011] The drive motor 7 is enclosed and installed inside the bulkhead 5 .

[0012] When the dregs in the soil cabin 5 began to accumulate, the drive moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com