Non-replacement construction method of reinforcing pipe jacking friction reduction slurry

A technology of anti-friction mud and construction method, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve problems such as unsatisfactory filling and reinforcement effects of cement slurry materials, unsuitable for large-section pipe jacking construction, and unfavorable control of ground subsidence, etc. , to achieve the effect of maintaining pressure, reducing pressure loss, and good reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

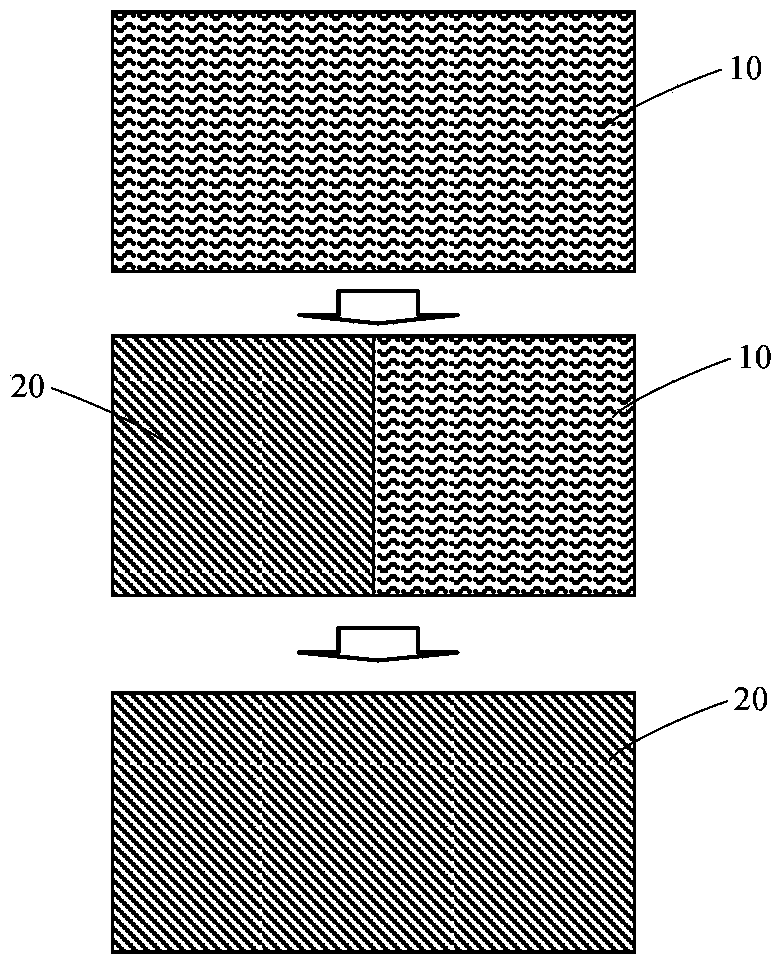

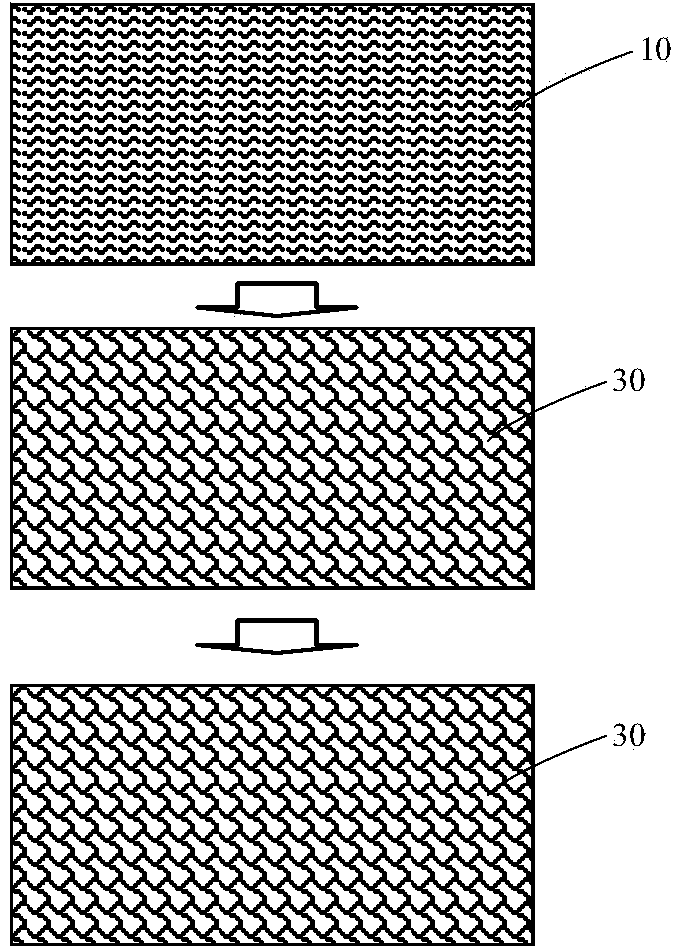

[0018] refer to figure 2 , shows the flow chart of the non-replacement construction method of the invention for strengthening the anti-friction mud for pipe jacking. The non-replacement construction method of reinforcing the anti-friction mud for pipe jacking of the present invention adopts a kind of solidified mud material, and does not need to replace the anti-friction mud during the construction process, and directly injects the solidified mud into the anti-friction mud, and is combined with the anti-friction mud After mixing, the strength is the same as that of the surrounding soil or higher than the strength of the soil, so as to reduce the disturbance of the ground during construction, and to a greater extent reduce ground settlement and tunnel leakage and waterproofing. The solidified slurry is mixed with cement, lime, and water in a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com