Metal structure corrosion protection and reinforcement method

A metal structure and corrosion protection technology, applied in chemical instruments and methods, anti-corrosion coatings, lamination, etc., can solve problems such as economic damage, corrosion of metal structures of facilities and equipment, and affect the normal operation of facilities and equipment, and achieve good reinforcement. The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

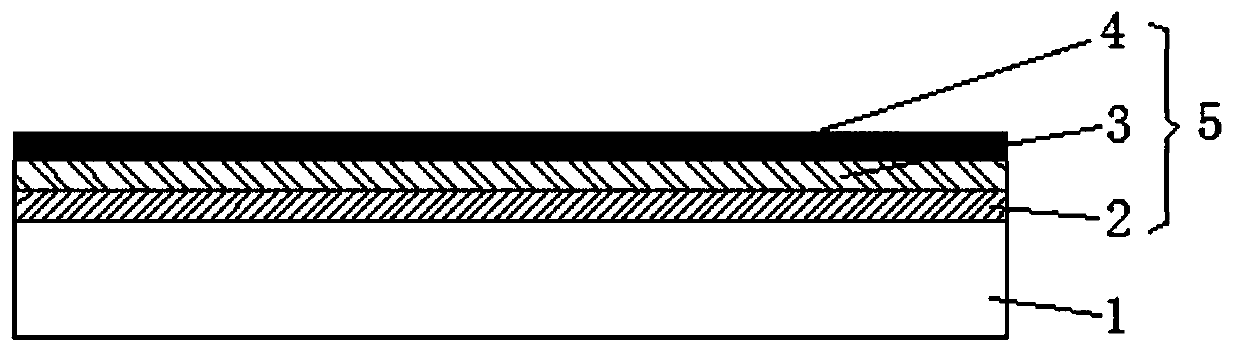

[0037] combined with figure 1 , the present invention provides a metal structure corrosion protection and reinforcement method, the method is suitable for metal substrate 1 corrosion protection and reinforcement, first metal substrate 1 is surface treated, then soaked with epoxy resin cut glass fiber cloth, soaked A good glass fiber cloth is laid on the surface of the metal base 1. After curing, putty or anti-corrosion primer is applied by scraping, and finally an anti-corrosion top coat is applied.

[0038] For the planar structure in metal matrix 1, the specific steps are as follows:

[0039] 1) Carry out surface treatment to the metal substrate 1, adopt mechanical grinding or sandblasting anti-corrosion to remove the loose metal oxide layer on the surface, apply silane coupling agent, and protect the surface treatment area to prevent it from being polluted.

[0040] 2) Select a suitable epoxy resin and mix it according to a certain ratio to ensure uniform mixing and avoid ...

Embodiment 2

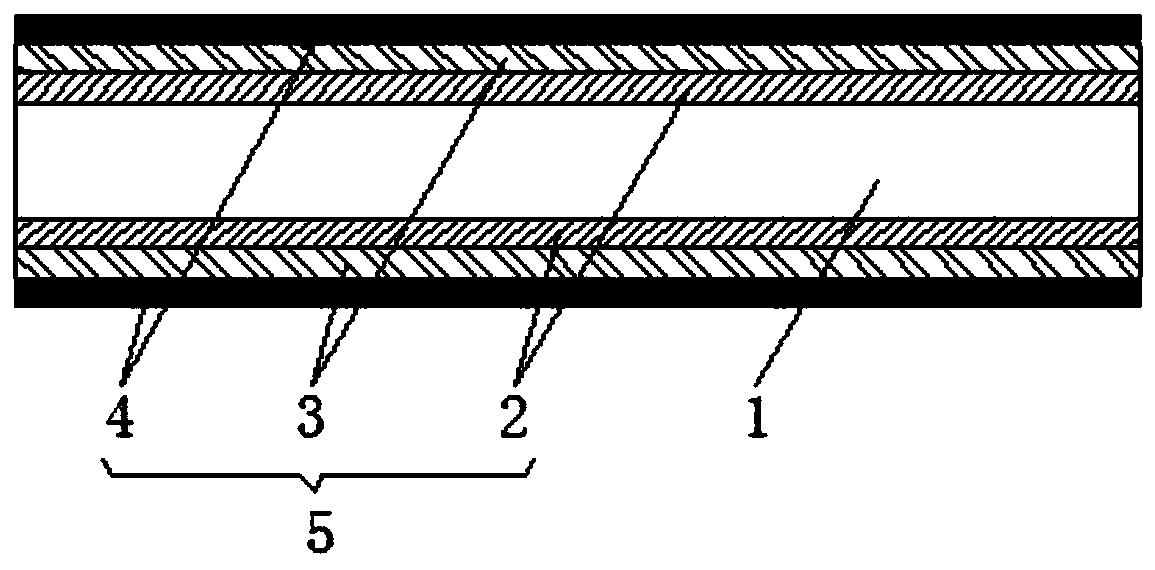

[0055] combined with figure 2 , the present invention provides a metal base 1 corrosion protection and reinforcement method, the method is applicable to the metal base 1 corrosion protection and reinforcement, first metal base 1 is surface treated, then soaked with epoxy resin cut glass fiber cloth, the The soaked glass fiber cloth is laid on the surface of the metal substrate 1. After curing, putty or anti-corrosion primer is scraped and coated, and finally the anti-corrosion top coat is applied.

[0056] For the planar structure in metal matrix 1, the specific steps are as follows:

[0057] 1) Carry out surface treatment to the metal substrate 1, adopt mechanical grinding or sandblasting anti-corrosion to remove the loose metal oxide layer on the surface, apply silane coupling agent, and protect the surface treatment area to prevent it from being polluted.

[0058] 2) Select a suitable epoxy resin and mix it according to a certain ratio to ensure uniform mixing and avoid m...

Embodiment 3

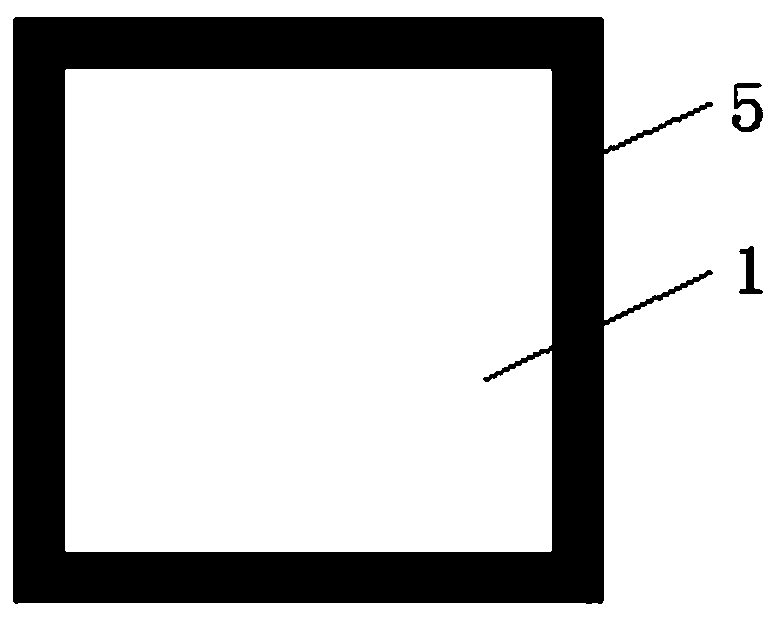

[0070] Embodiment 3 is the same as Embodiment 1, except that for the columnar body or similar structure in the metal substrate 1, it is wrapped with glass fiber cloth by the method of step 1)-step 8), and then the primer is applied , topcoat to form a comprehensive anti-corrosion reinforcement layer, such as image 3 , 4 shown.

[0071] In the present invention, the silane coupling agent is selected from one or more of KH550, KH560, and KH570.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com