Packaging mold of ternary catalytic converter and packaging method thereof

A catalytic converter and packaging method technology, which is applied in the field of automotive exhaust system packaging, can solve problems such as cylinder positioning, large fit gap changes, missing welding and virtual welding, etc., to meet axial thrust detection, improve product quality, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings.

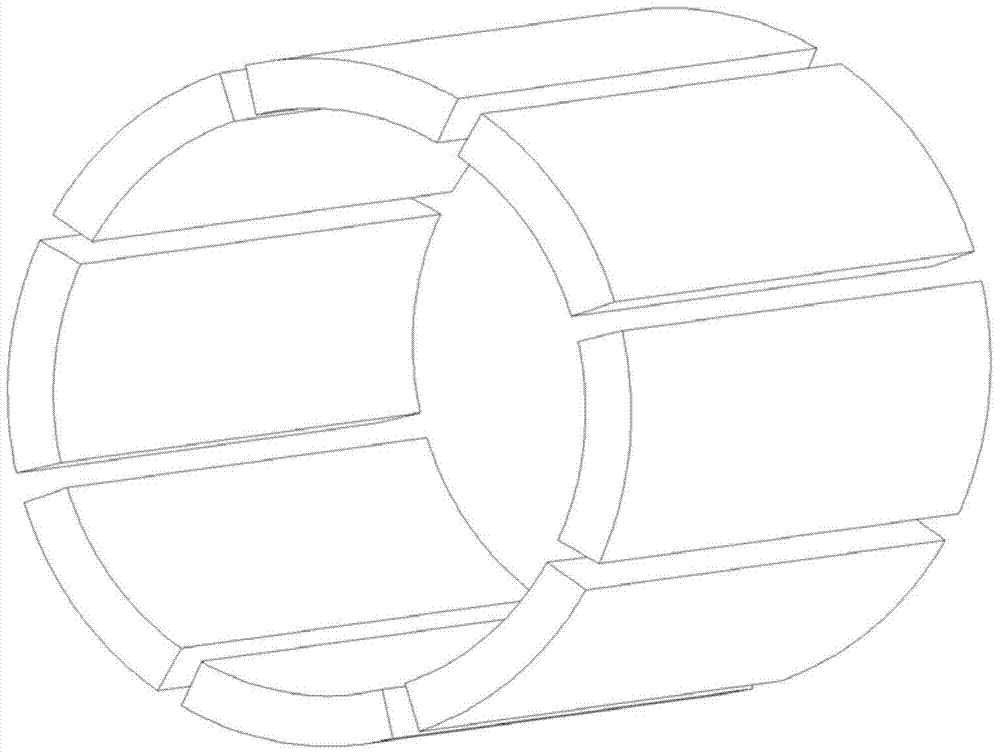

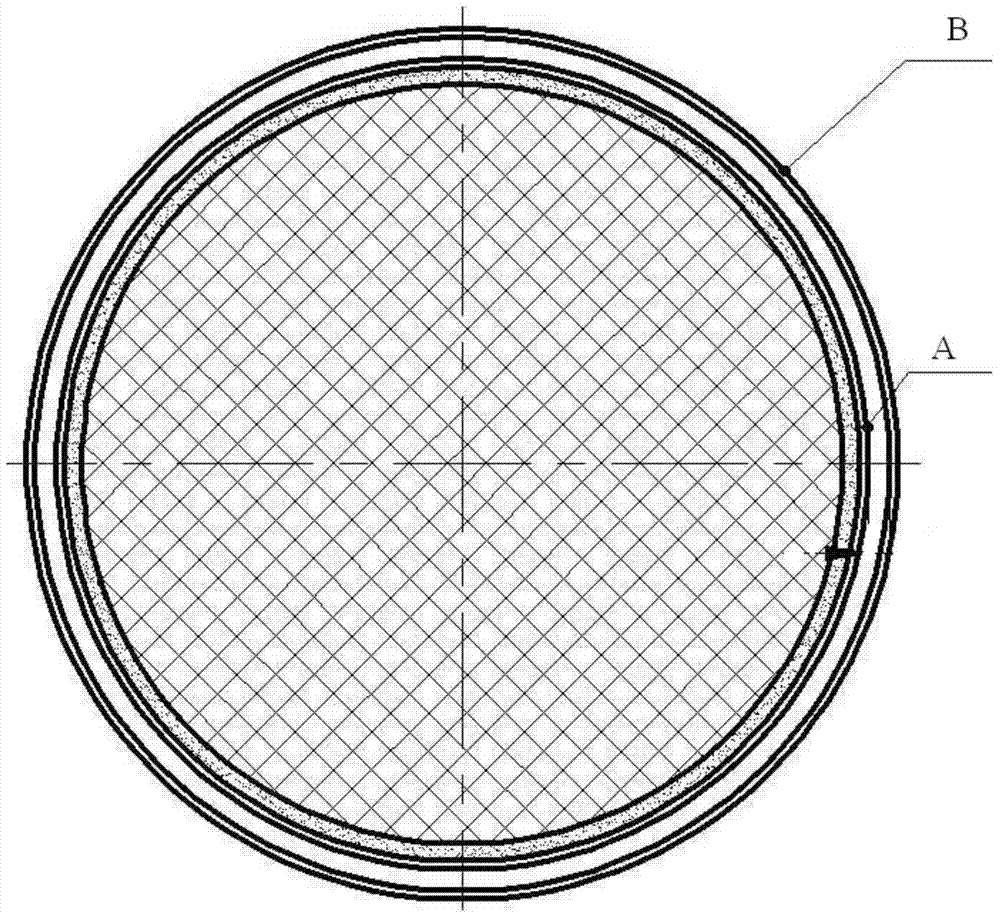

[0024] like image 3 As shown, the packaging mold of the three-way catalytic converter includes a cylindrical mold body, and the mold body is made up of 8 mold sheets of the same size; Figure 3a shown) and two-slot die pieces (such as Figure 3b As shown), the three-slot mold sheet 1 and the two-slot mold sheet 2 are placed in pairs; as Figure 3a As shown, the cross-section of the three-slot mold sheet is fan-shaped, and the inner and outer surfaces are arc surfaces respectively. Three parallel grooves are respectively arranged at the two ends and the middle of the inner surface, and each groove is respectively along the three grooves. The curved surface setting of the groove piece; such as Figure 3b As shown, the cross-section of the two-groove mold sheet is fan-shaped, and the inner and outer surfaces are arc surfaces respectively. Two parallel grooves are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com