High-tension test apparatus for automobile ignition coil

An automobile ignition coil and high-voltage test technology, which is applied in the direction of mechanical equipment, engine ignition, spark ignition controller, etc., can solve the problem that the rubber sleeve is easy to age and harden, the insulation performance of the ignition coil cannot be judged, and the reliability of the ignition system is affected. The use of spark plugs Lifespan and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

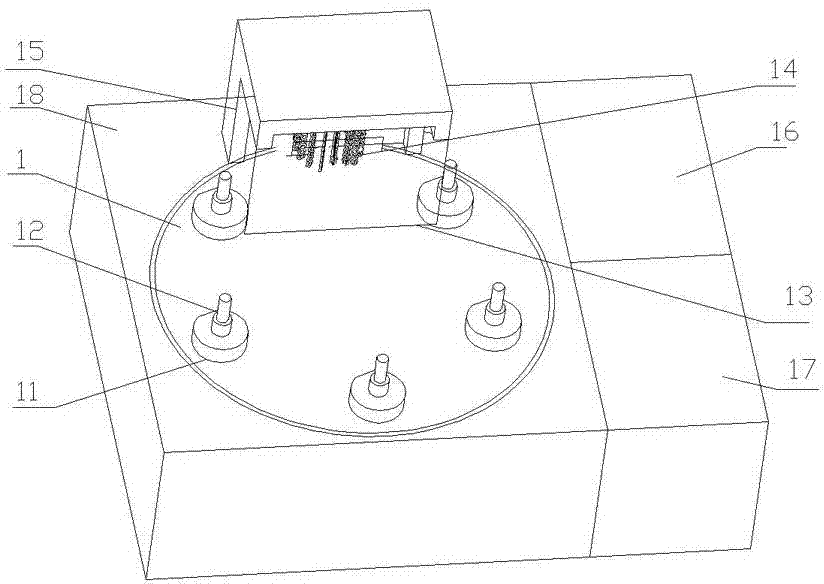

[0024] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a high-voltage test equipment for an automobile ignition coil of the present invention. A kind of automobile ignition coil high-voltage test equipment, the equipment is provided with a base 18; the center of the base 18 is provided with a turntable 1; the turntable 1 is circular; A plastic tube 11 is embedded inside; the plastic tube 11 is equipped with conductive copper columns 12; the conductive copper columns 12 are evenly distributed on the periphery of the turntable 1; the turntable 1 is also provided with a fixed door cavity 15.

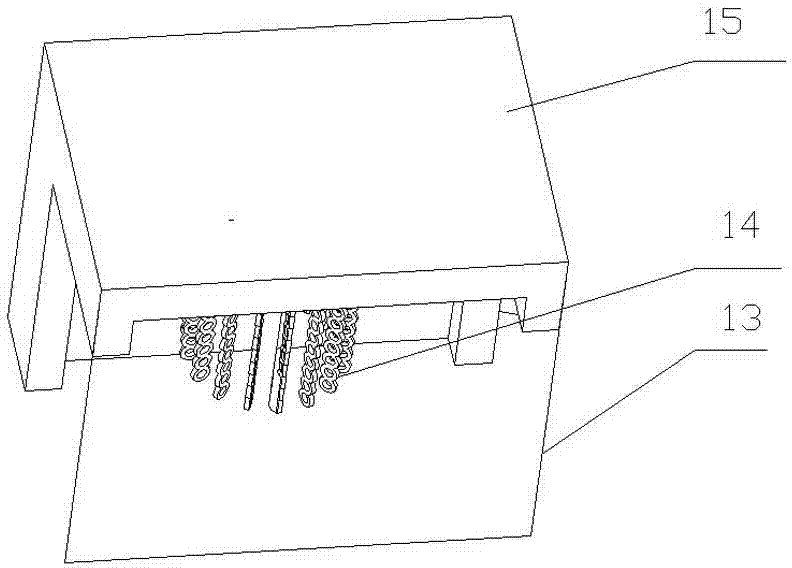

[0025] Please refer to figure 2 , figure 2 It is a schematic diagram of the position structure of the fixed door cavity, the conductive chain, and the glass baffle in the high-voltage test equipment for the automobile ignition coil of the present invention. The fixed door cavity 15 is fixed on the base 18; the fixed door cavity 15 is internally connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com