Design method of arc bevel gear tooth surface based on different tooth profile angular spherical tooth profile

A technology of tooth profile angle and bevel gear, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., and can solve the problem that gears cannot meet the requirements of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

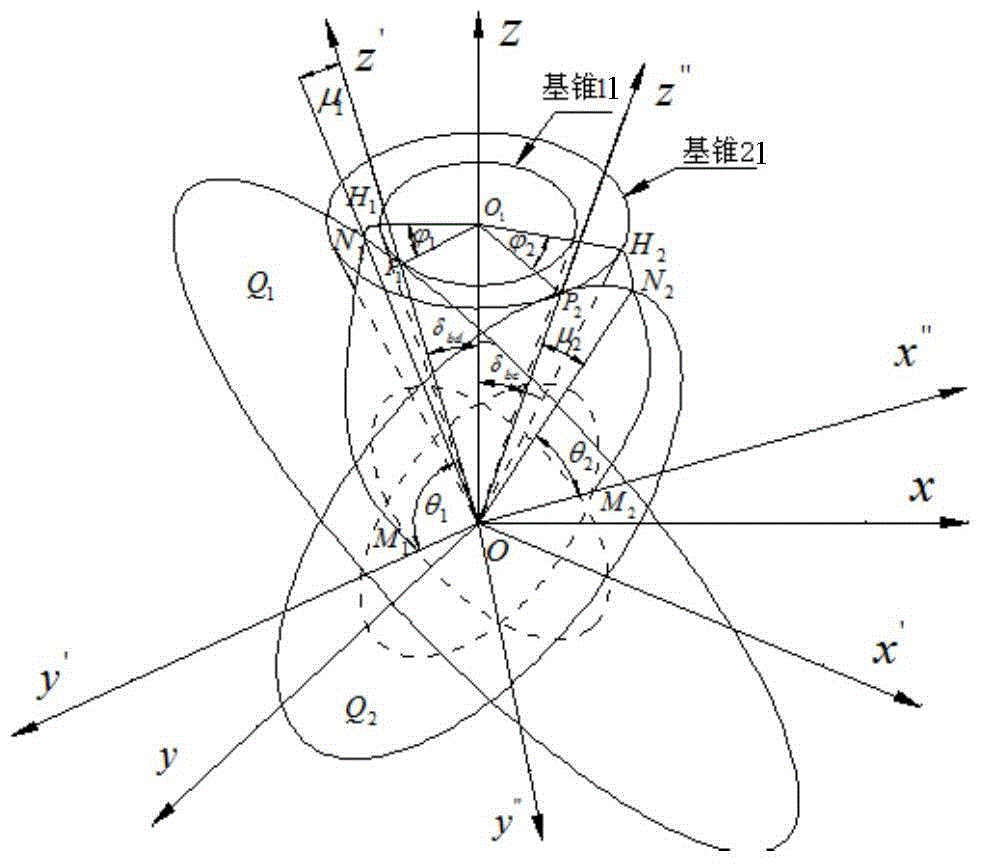

[0040] Arc bevel gears based on different tooth profile angles have different tooth profile angles on both sides, the section at the root of the tooth becomes thicker, and the tooth thickness, tooth tip fillet, and tooth root fillet of the driving side and the non-driving side change. Therefore, it is very necessary to propose a calculation method for the design and calculation of the circular bevel gear tooth surface based on different tooth profiles and angular spherical tooth profiles.

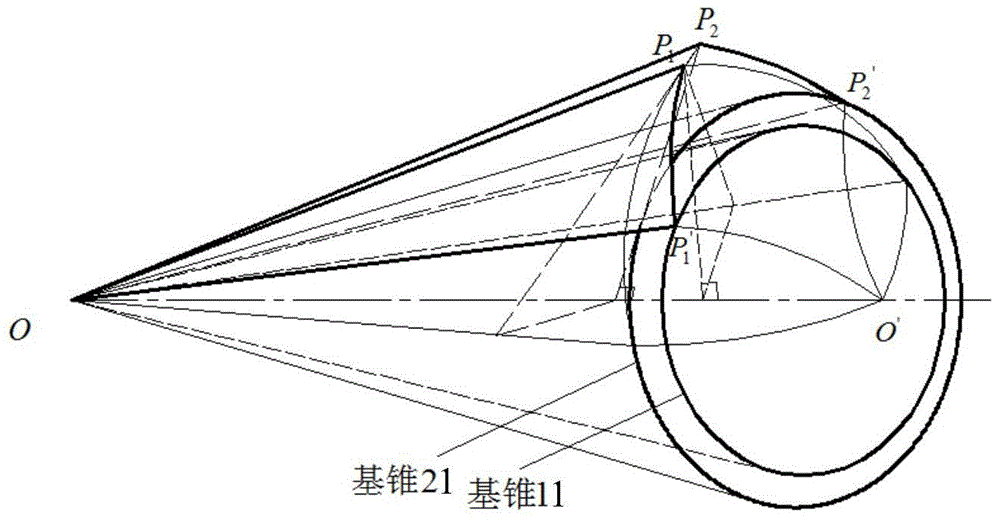

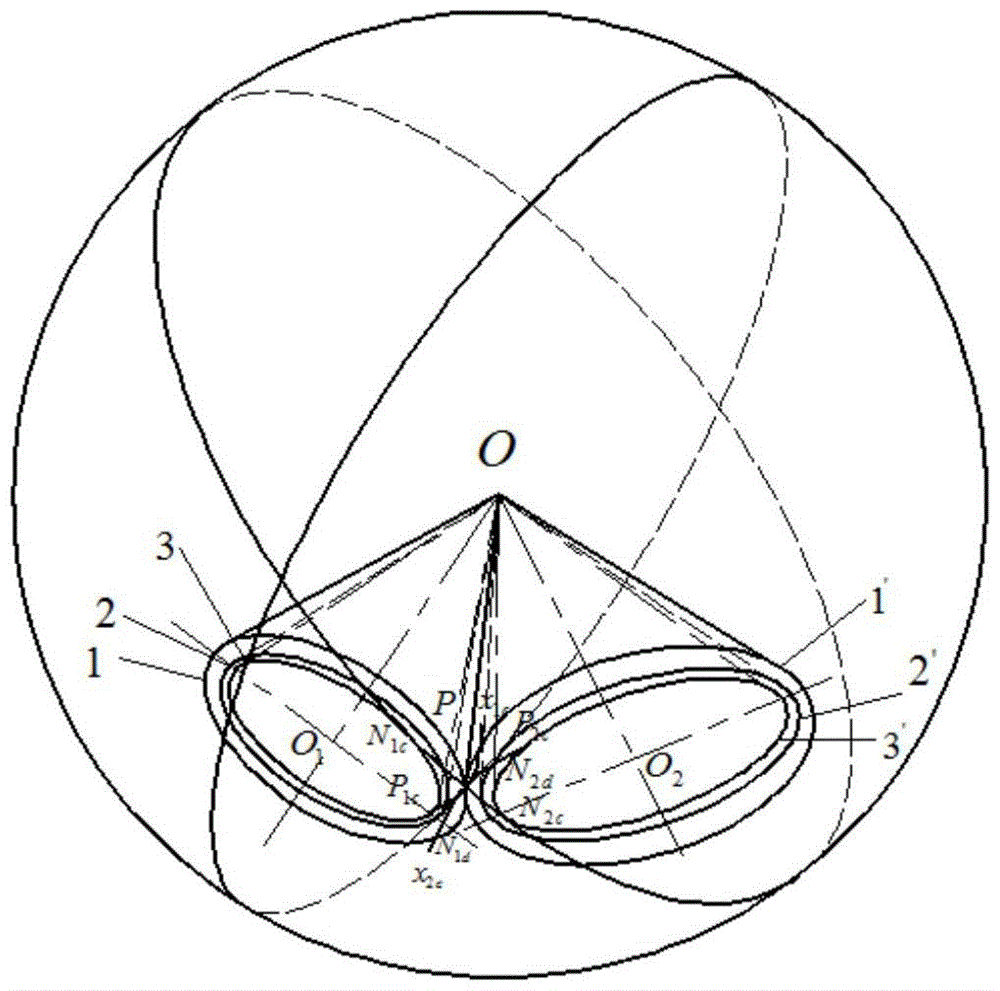

[0041] Arc bevel gears with different tooth profile angles have two different base circles. The two base cones have two different meshing planes, which perform pure rolling along their respective meshing surfaces. The two base cones have a common pitch cone and mesh with each other. The two conical surfaces of a pair of bevel gears with different tooth profiles are tangent. Such as figure 1 As shown, the drive side tooth surface base cone OP 1 'O' and non-drive side tooth flank OP' 2 O' ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com