Check sealing structure for smoke exhaust equipment

A sealing structure and flue gas technology, which is applied in the direction of mechanical equipment, exhaust gas exhaust devices, lighting and heating equipment, etc., can solve the problems of not being blown open, elastic seals and exhaust tube ports stuck tightly, and smoke cannot be discharged, etc., to achieve The effect of ensuring indoor air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

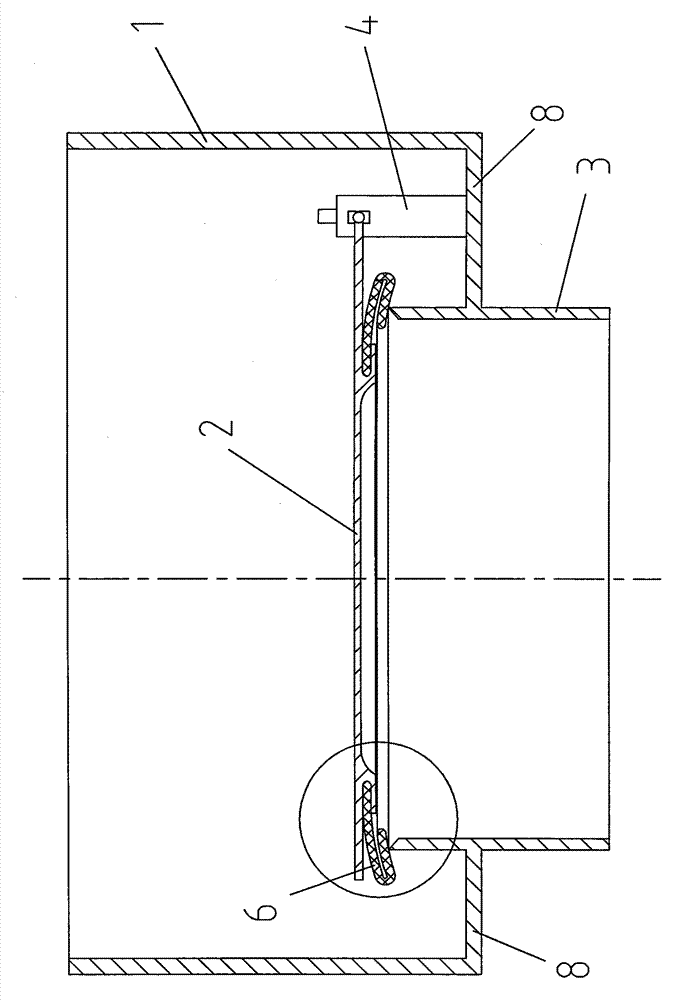

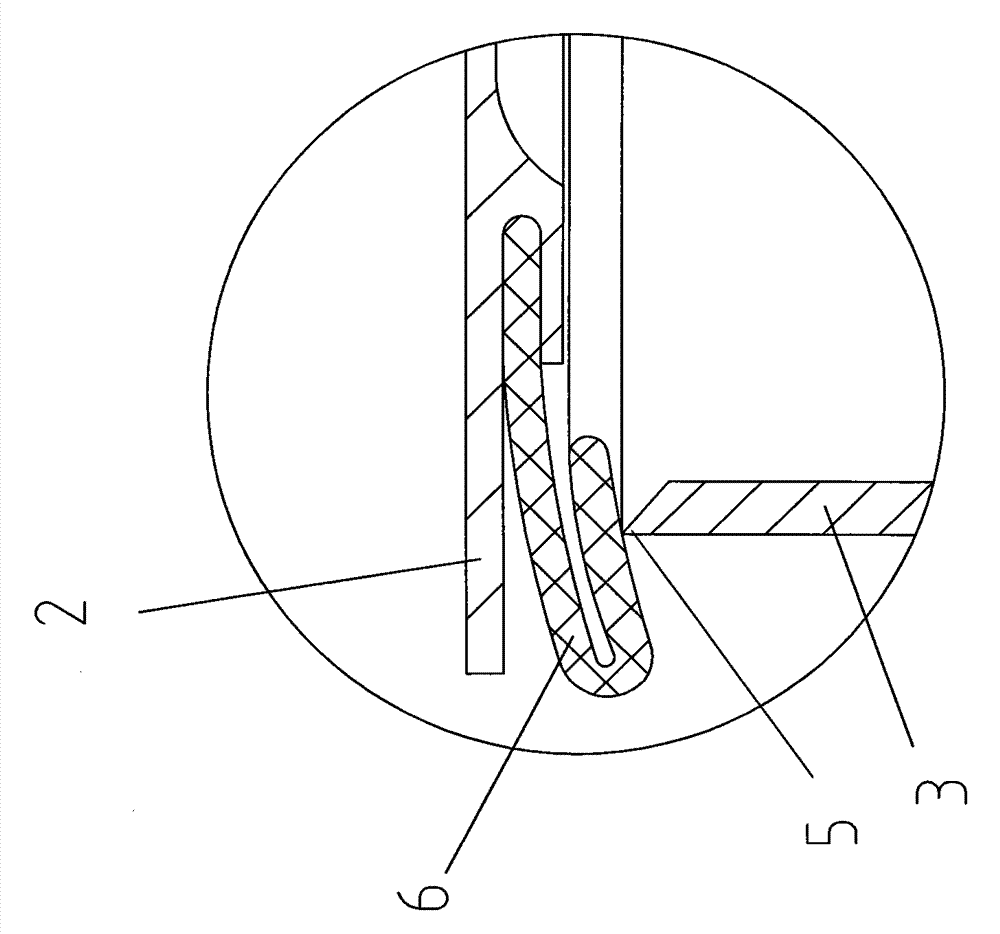

[0010] Embodiment 1: as figure 1 , 2 As shown: 1 is the valve body, 3 is the discharge cylinder, the discharge cylinder 3 is located inside the valve body 1, and the discharge cylinder 3 and the valve body 1 are connected by a connecting plate 8 . The inner side of the upper port of the discharge cylinder 3 is processed with a slope to form a top edge 5. 2 Check plate, one side of the check plate 2 is connected to the bracket 4 through a rotating shaft, and the bracket 4 is fixedly connected to the connecting plate 8 or the valve body 1 by screws or bonding. The valve body 1 and the discharge tube 3 are in the shape of a cylinder or a square tube or other shapes, and the connecting plate 8, the discharge tube 3 and the valve body 1 can be of an integral structure. The check plate 2 is plate-shaped. A groove is processed on the periphery of the non-return plate 2, and the annular elastic seal 6 is set in the groove, that is, the inner side of the elastic seal 6 is placed ins...

Embodiment 2

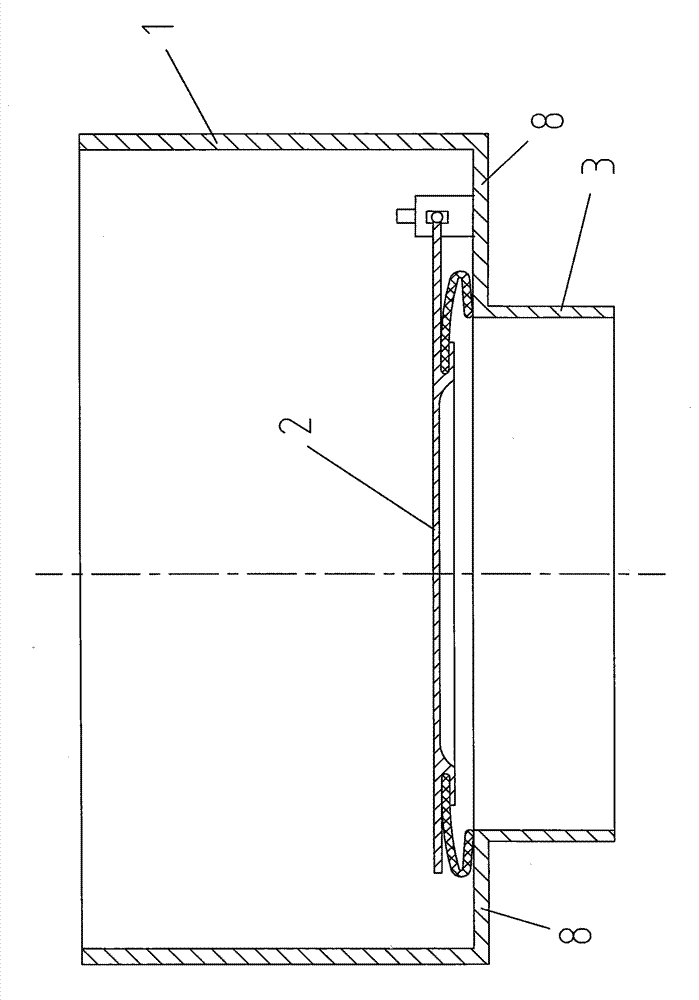

[0011] Embodiment 2: as image 3 As shown: The difference from Embodiment 1 is that the port of the discharge cylinder 3 is flush with the connecting plate 8 to form a plane, and the elastic sealing member 6 can directly contact the plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com