Multi-unit fume exhaust device

A fume exhaust device and multi-type technology, applied in heating methods, oil fume removal, household heating and other directions, can solve the problems of yellowing of roasted paste, inconvenient operation, large temperature fluctuation, etc., to improve quality, reduce waste, prevent The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

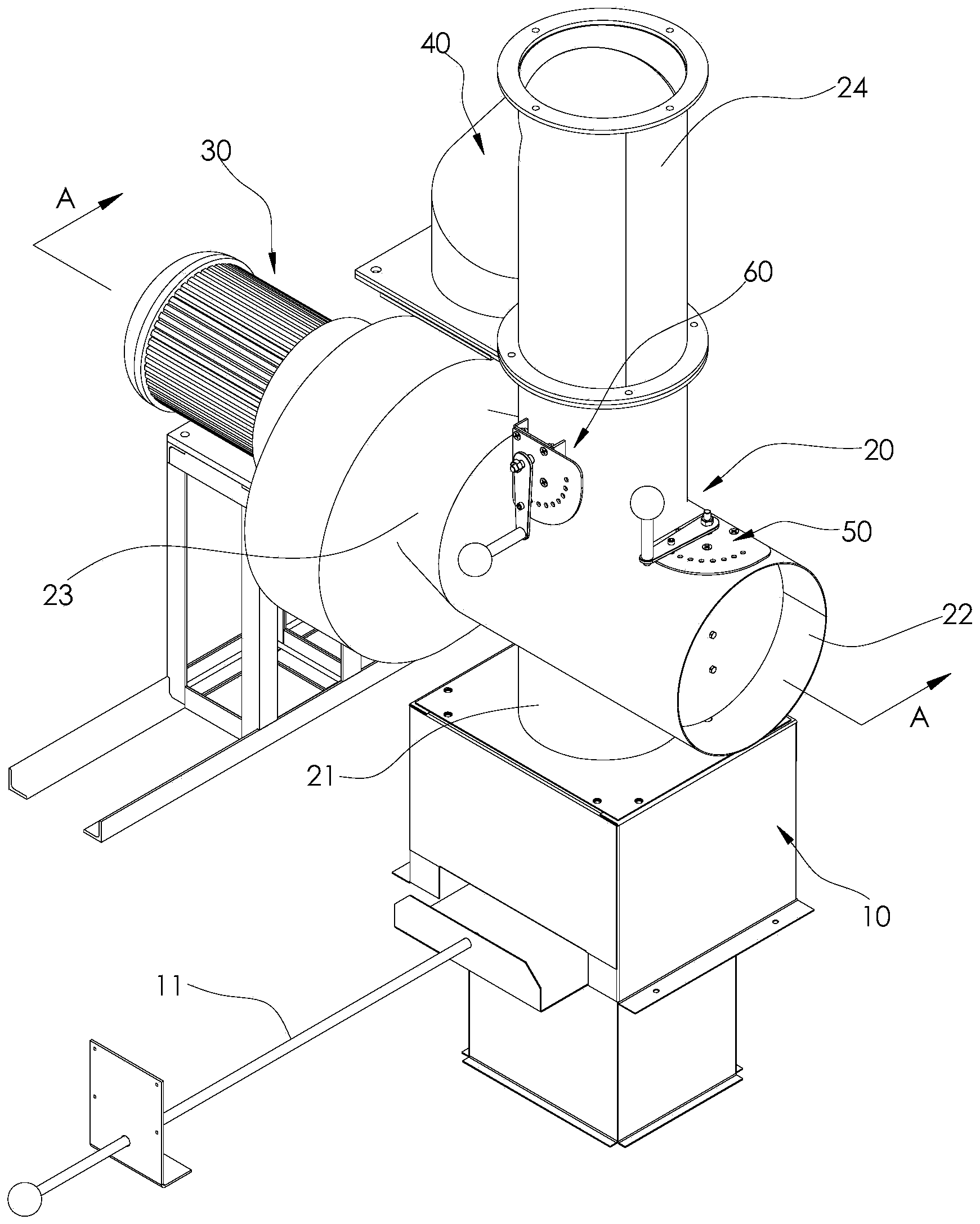

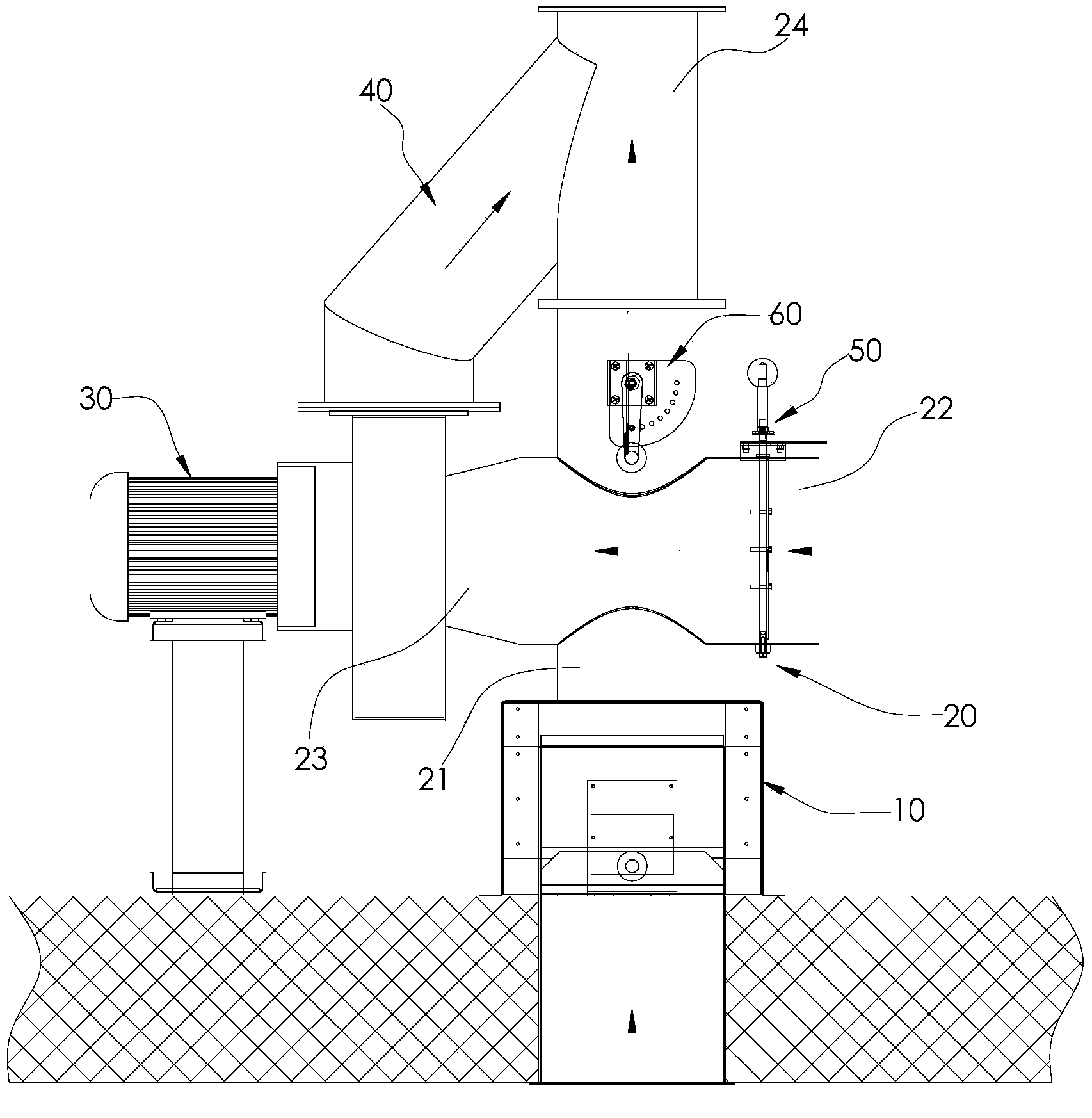

[0022] Such as figure 1 , 2 As shown, it is a multi-component smoke exhaust device of the present invention, which includes a four-way pipe 20, a first control valve 50, a second control valve 60, an induced draft fan 30 and a communication pipe 40, and the four-way pipe 20 has four The four joints are respectively the first joint 21 communicated with the smoke exhaust pipe of the oven, the second joint 22 communicated with the external environment, the third joint 23 facing the second joint 22, and the first joint 23 connected with the first joint. 21 is facing the fourth joint 24, wherein the first joint 21 is used to introduce the flue gas inside the oven into the inside of the four-way pipe 20, and the second joint 22 is used to transport the air in the external environment to the four-way pipe 20 , the fourth joint 24 is used to discharge the smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com