Device for measuring heat conductivity coefficient of liquid on basis of transient plane source method

A technology of transient plane and thermal conductivity, applied in the direction of material resistance, etc., can solve the problems of high liquid thermal conductivity measurement results and increased data dispersion rate, and achieve the effects of suppressing natural convection, high output power, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

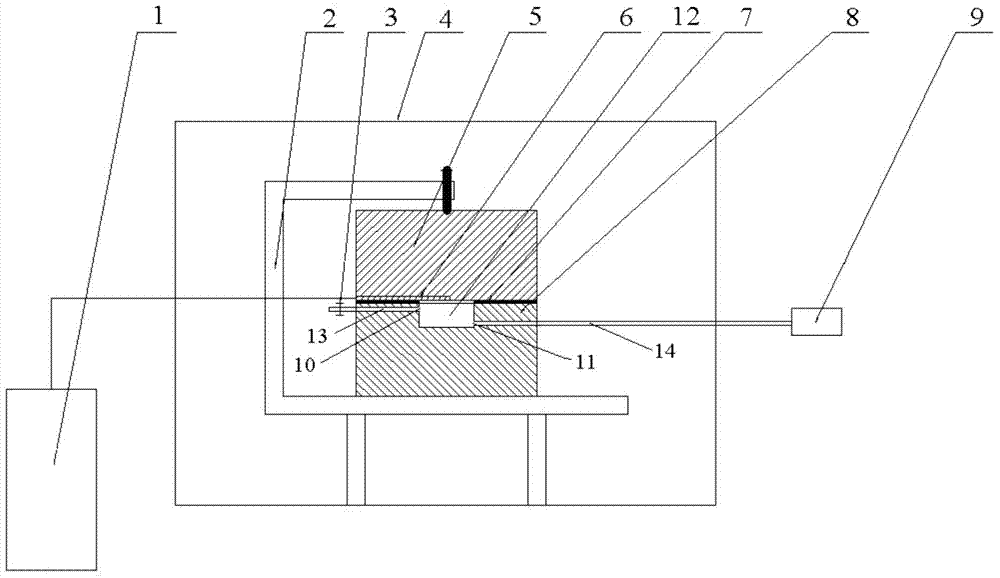

[0017] Specific Embodiment 1: This embodiment is a device for measuring liquid thermal conductivity based on the transient plane heat source method, including a computer 1, a sample holder 2, a valve 3, a sample chamber 4, a solid standard sample 5, a probe 6, and a gasket 7 , aluminum alloy 8 and liquid injector 9, liquid pool 12, first plastic tube 13 and second plastic tube 14;

[0018] The sample chamber 4 is provided with a sample holder 2, and the aluminum alloy 8 is arranged on the sample holder 2; the upper end of the aluminum alloy 8 is provided with a liquid pool 12; the two ends of the liquid pool 12 are provided with a first small hole on the wall of the pool 10 and the second small hole 11; one end of the first plastic tube 13 communicates with the first small hole 10, and the other end of the first plastic tube 13 communicates with the valve 3; one end of the second plastic tube 14 communicates with the second small hole 11 is connected, and the other end of the ...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 2 is that the length of the groove with a depth of 25 μm is equal to the length of the probe 6 . Other steps are the same as in the second embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the tip of the probe 6 is above the center of the liquid pool 12 . Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com