Metal material rapid forming method and device based on free falling body

A technology of metal materials and free fall, which is applied in the direction of safety devices, metal processing equipment, process efficiency improvement, etc., can solve the problems that metal materials cannot be processed and formed, so as to suppress natural convection and buoyancy, reduce work intensity, and effectively Conducive to the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment provides a method and device for rapid prototyping of metal materials based on free fall, which can realize rapid prototyping of metal materials under the condition of supernormal solidification.

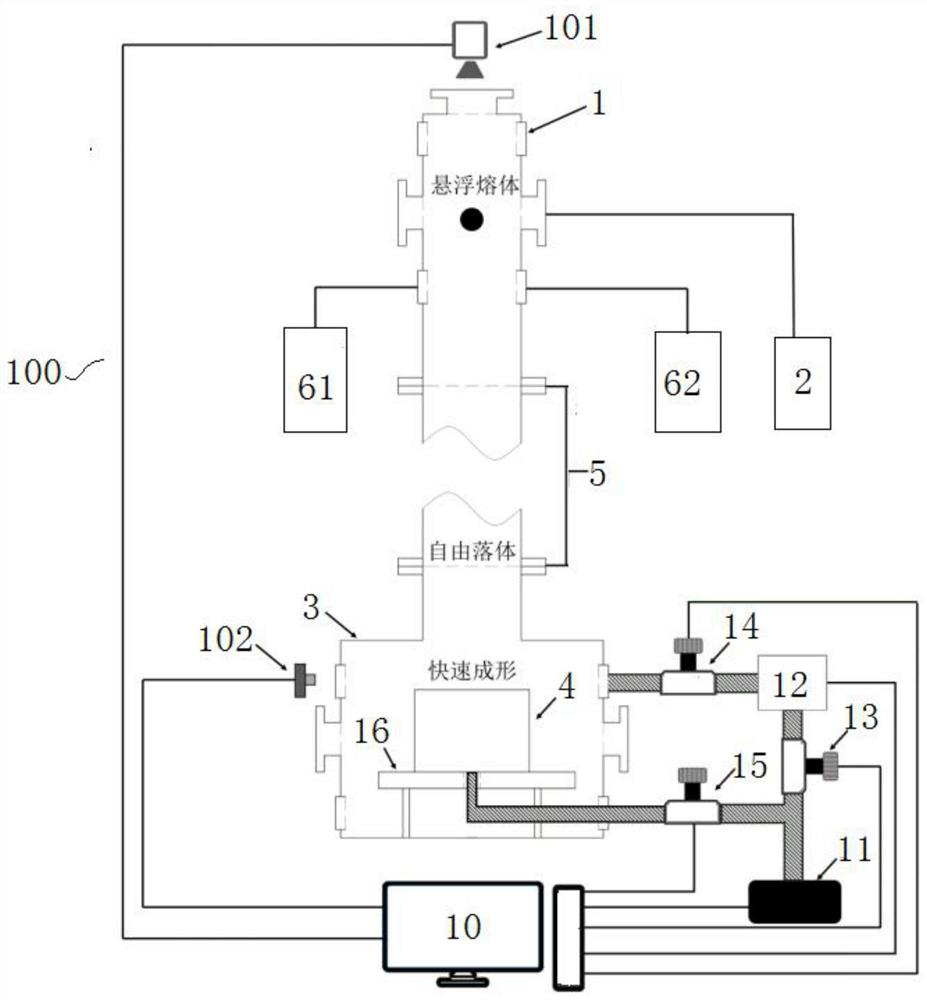

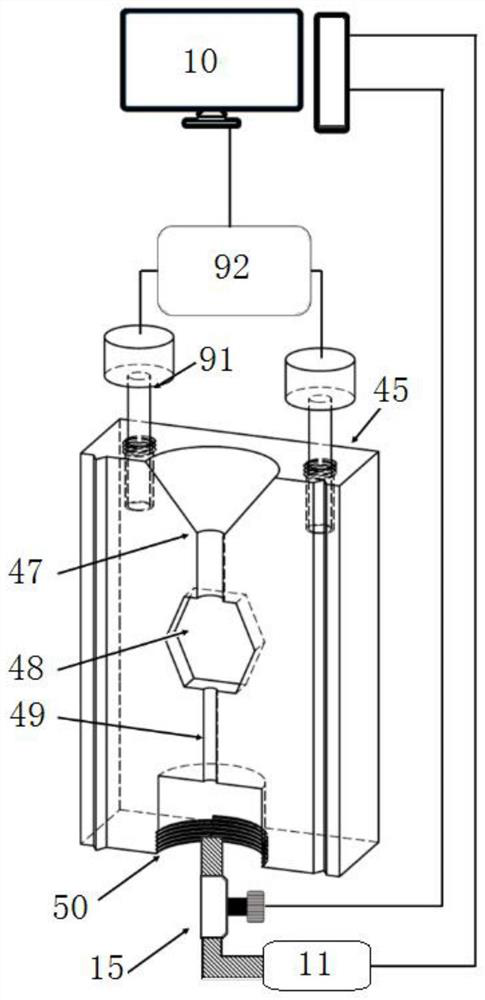

[0077] Such as Figure 1~6 As shown, this embodiment provides a rapid prototyping device 100 for metal materials based on free fall, specifically a rapid prototyping device for supernormally solidified metal, which includes:

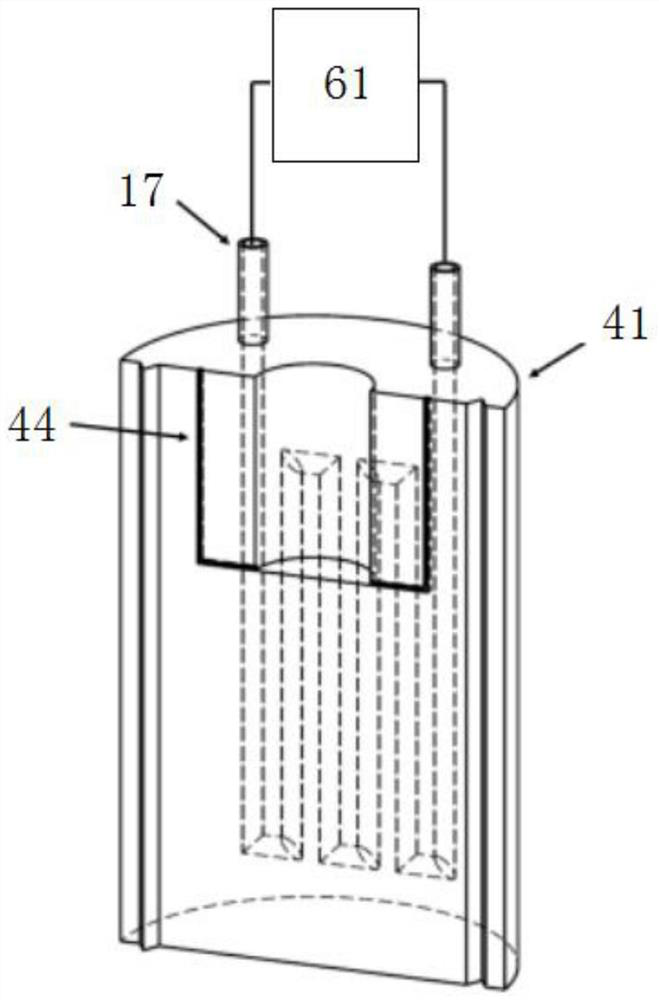

[0078] The first vacuum chamber 1 , the intermediate vacuum chamber 5 and the second vacuum chamber 3 are sequentially arranged in communication from top to bottom. Among them, the first vacuum chamber 1 is preferably a cylindrical vacuum chamber with a diameter of 500-2000 mm, which is mainly used for the suspension melting of the metal material (metal ball) to be processed, and realizes the non-container state of the metal melt; the intermediate vacuum chamber 5 is preferably a diameter of The 500-2000mm cylindrical vacuum chamber is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com