A space camera secondary mirror support structure

A bracket structure and space camera technology, applied in installation, optics, instruments, etc., can solve the problems of high obscuration ratio, poor temperature adaptability, heavy weight, etc., and achieve the effect of reliable and uniform connection and improved temperature adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

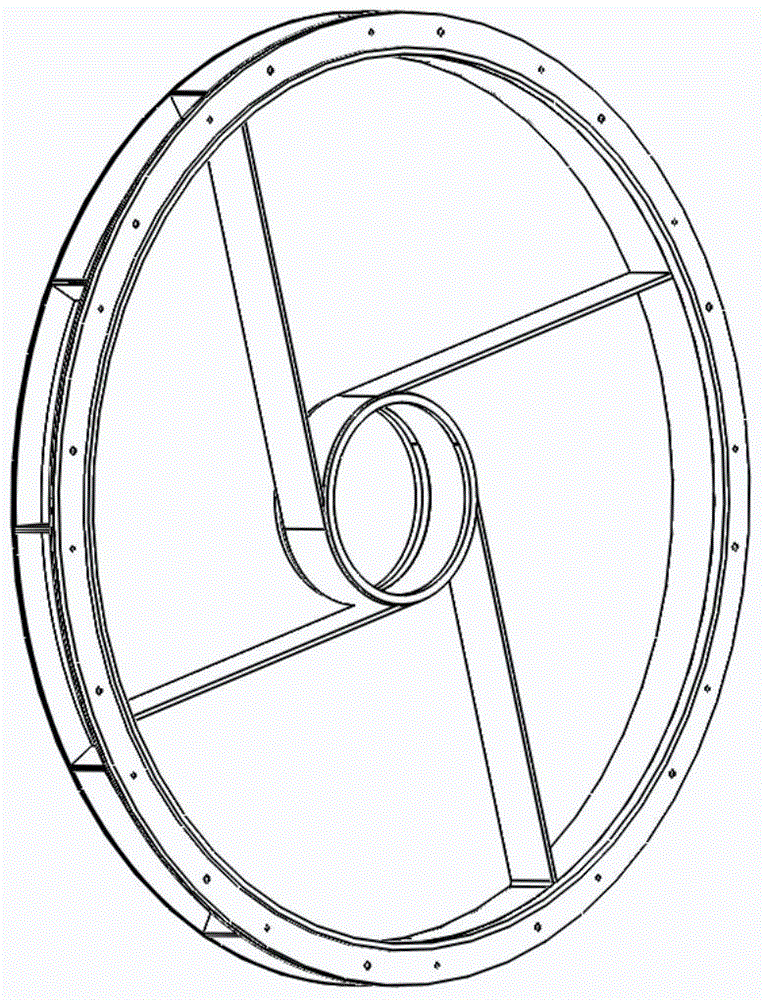

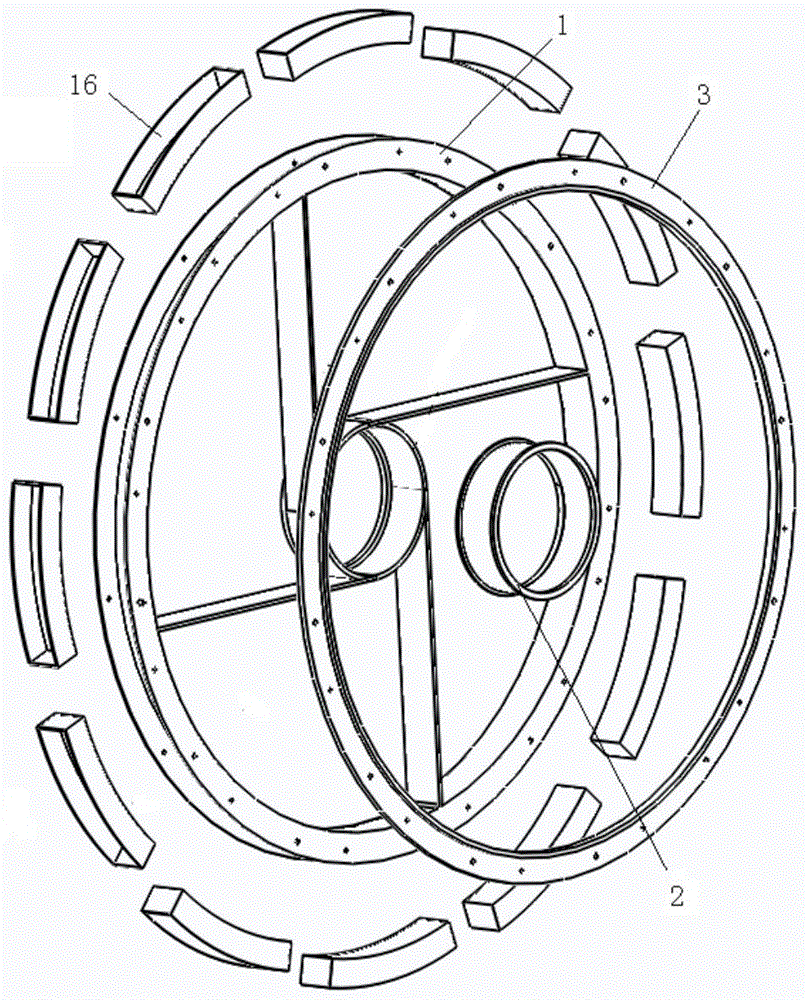

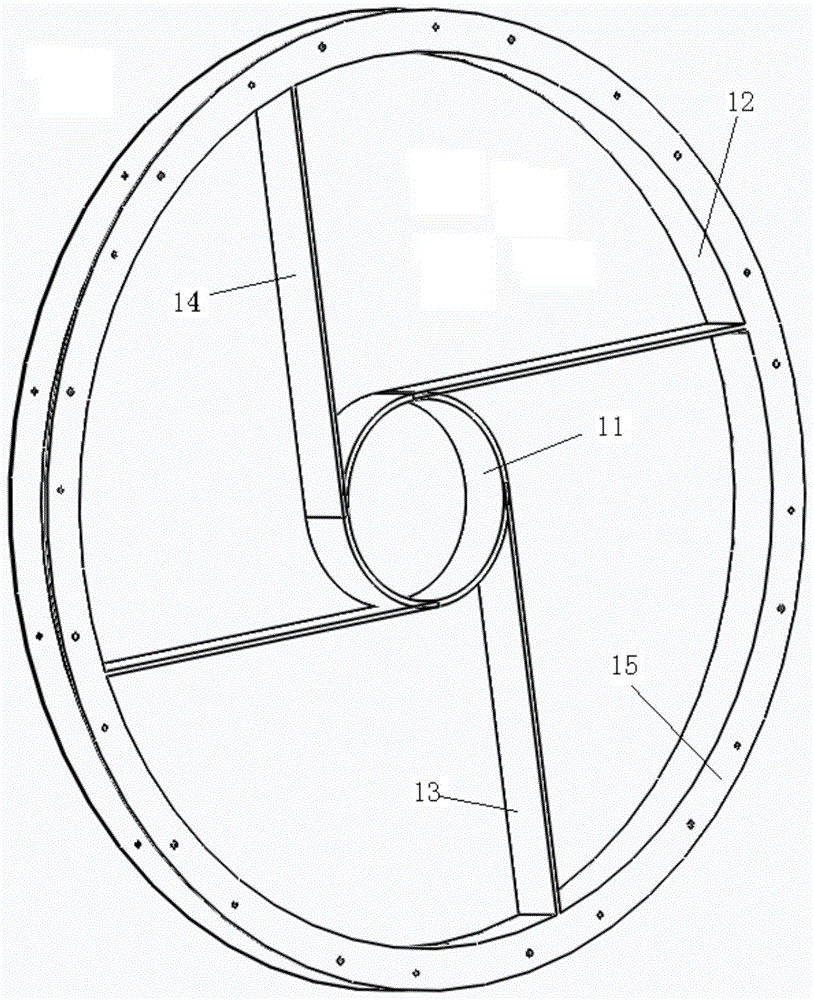

[0032] The invention includes a secondary mirror bracket 1, a metal insert 2 and a metal flange 3. The secondary mirror bracket 1 is laid by a high-modulus carbon fiber reinforced epoxy resin-based composite material laminate, and is formed by using different molds in the laying process Different structures are finally assembled together, sucked glue, and solidified in an autoclave. The material of secondary mirror bracket 1 is made of high modulus carbon fiber reinforced resin-based composite material, which solves the contradiction between high stiffness and light weight. Good vibration suppression effect and temperature stability.

[0033] The secondary mirror support in the present invention includes an inner ring 11, an outer ring 12, and a tangential rib 13 between the inner ring and the outer ring. The inner ring is formed by winding the metal insert 2 as a mandrel, and the prepreg The material forms four-wing tangential ribs. When the length of the four ribs changes d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com