Bayes-method-based spaceflight valve part fault diagnosis method in machining process

A technology for parts processing and fault diagnosis, which is used in program control, instrumentation, computer control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

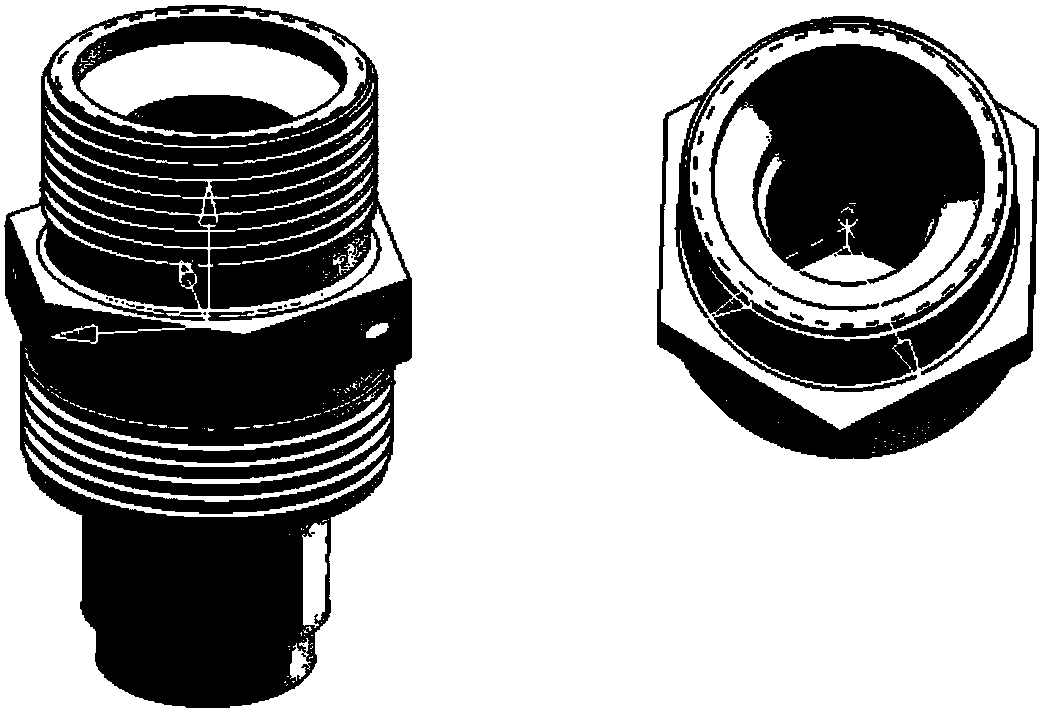

[0052] The technical scheme of the present invention will be further described below with reference to the accompanying drawings, taking the mean value control diagram of a certain type of bushing parts as an example.

[0053] like Figure 1 to Figure 7 Shown, the inventive method comprises the following steps:

[0054] The first step: Obtain the control chart of the machining process data of aerospace valve parts.

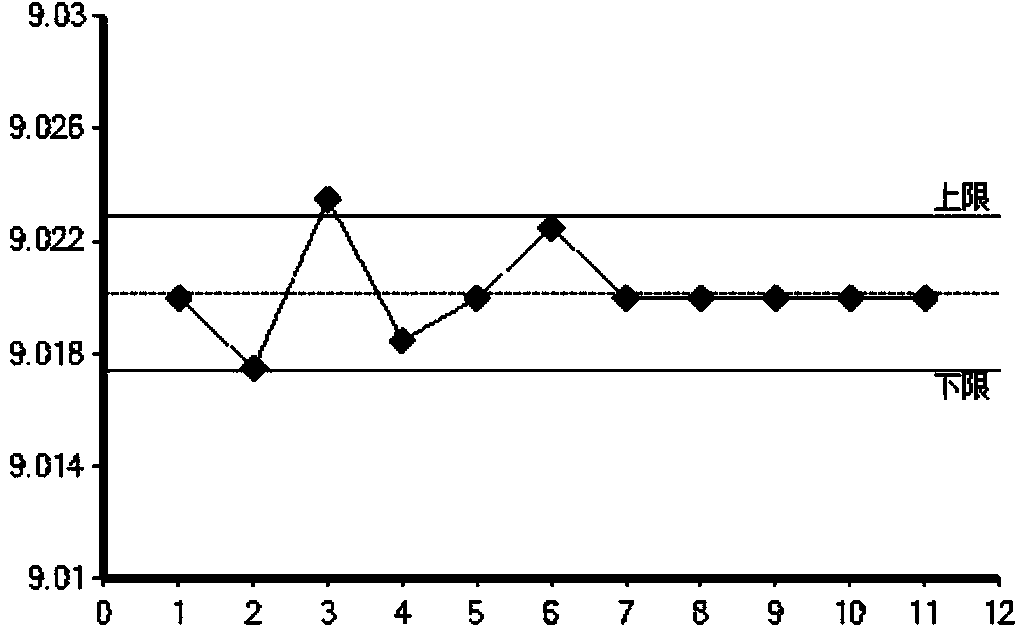

[0055] Through the quality monitoring of the key process (inner hole φ9mm) in the bushing process, the processing data of the key process is measured in time series, and they are drawn into four types of control charts. Here, the mean value control chart is taken as an example. like figure 2 shown.

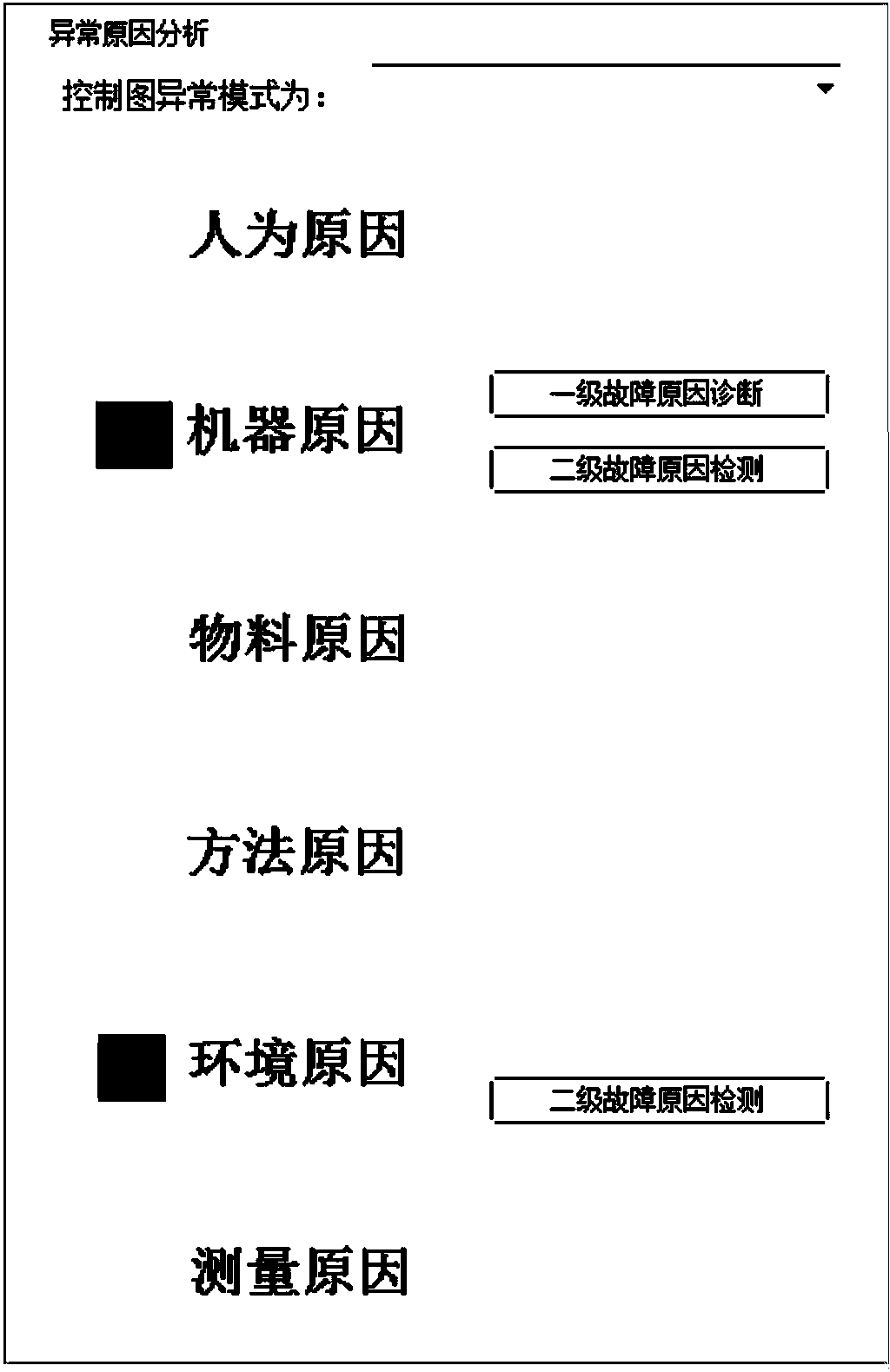

[0056] The second step: pattern recognition of aerospace valve parts processing control diagram.

[0057] There are 6 abnormal modes of the control chart, which are: mean increasing or decreasing trend, data points beyond the control limit, mean value shifting up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com