Method for optimizing cutting parameters considering machining energy efficiency

A technology of cutting parameters and energy efficiency, which is applied in the field of mechanical cutting and can solve problems such as increased energy consumption and the impact of solution results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

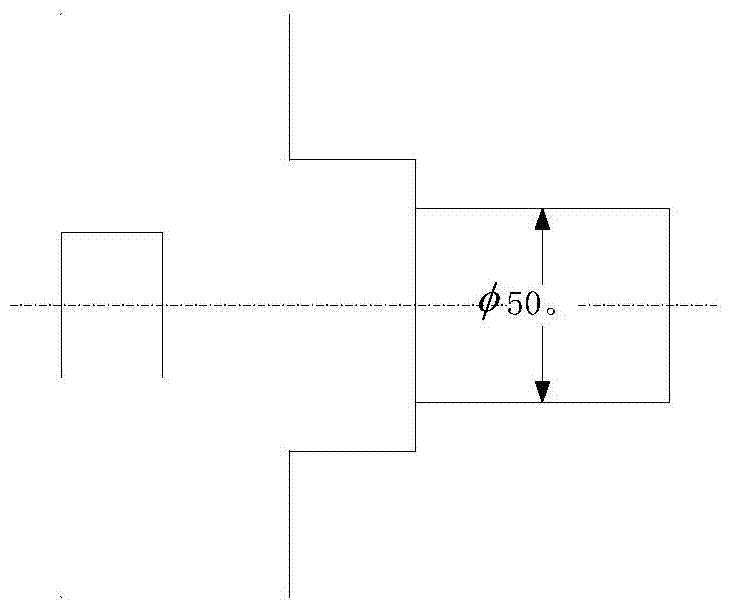

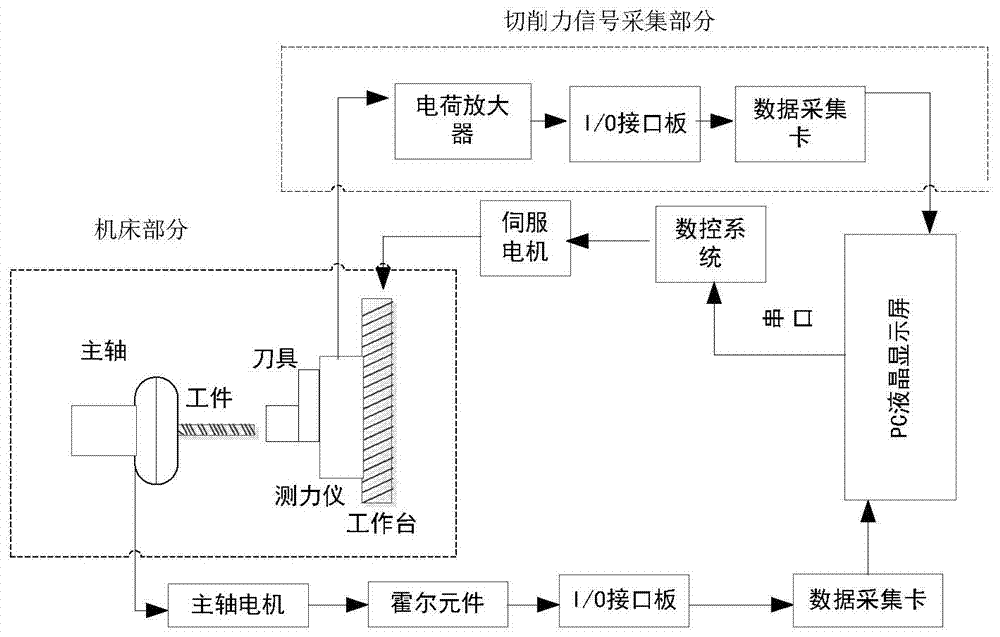

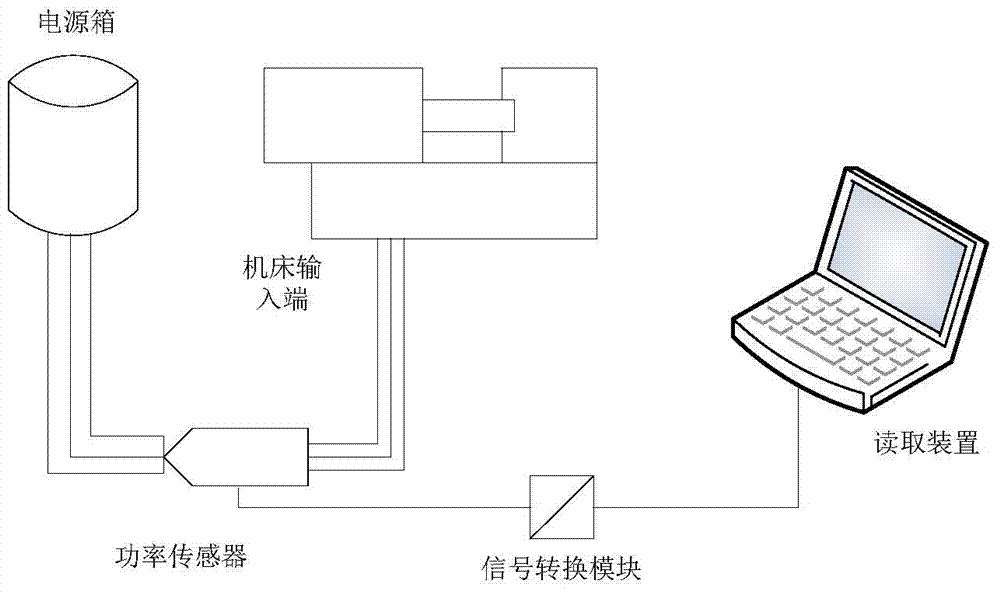

[0120] In order to verify the present invention, carry out cutting test by being equipped with Huazhong numerical control system CK60 numerical control lathe, workpiece (No. 45 hot-rolled steel) cutting length is 100mm, and diameter is 50mm, and cutting processing is as attached figure 1 shown. Using Kistler dynamometer and NI virtual instrument to collect cutting force signals, the three-dimensional cutting force can be obtained. The cutting force measuring device is attached figure 2 shown. Among them, the CNC lathe tool adopts the coated carbide tool MSSNR2525M12 with a leading angle of 45 degrees. In addition, both standby power and no-load power are measured by WB9128 three-phase power sensor, and the power measurement device is as attached image 3 shown.

[0121] In order to study the relationship between the no-load power of the machine tool and the spindle speed, 18 groups of experiments were carried out. The speed ranged from 145r / min to 1500r / min, which was main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com