Cable well safety operation monitoring system and monitoring method based on network communication technology

A technology for network communication and safe operation, applied in the field of safe operation monitoring of cable wells, can solve the problems of imperfect monitoring function of safe operation of cable wells, single monitoring parameters, etc., and achieve the effects of reliable performance, strong compatibility and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

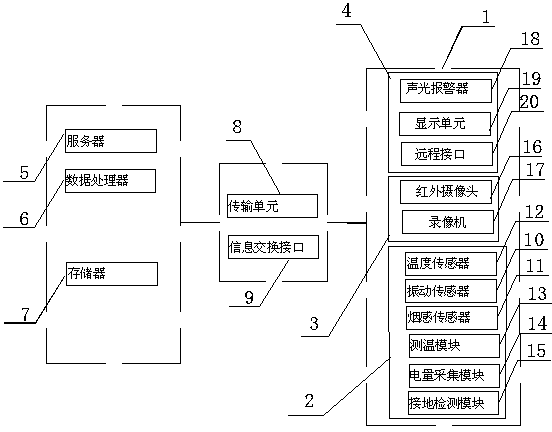

[0024] Such as figure 1 As shown, the cable well safety operation monitoring system and monitoring method based on network communication technology include an on-site module 1 installed in the cable well and a control module 2 remotely connected to the on-site module. The on-site module and the control module are connected through a network communication device 3 connections, the local module 1 includes an acquisition unit 2, a monitoring unit 3 and an alarm unit 4, the control module 2 includes a server 5 and a data processor 6 connected thereto, and a memory 7, and the network communication device includes a transmission unit 8 and an information exchange interface 9.

[0025] The acquisition unit includes an environmental information acquisition unit and a cable operation information acquisition unit. The environmental information acquisition unit includes a vibration sensor 10, a smoke sensor 11, and a temperature sensor 12 distributed in the cable shaft. The cable operati...

Embodiment 2

[0032] The cable well safety operation monitoring system and monitoring method based on network communication technology are different from Embodiment 1 in that the infrared camera is installed with a preset pan / tilt, and the load-bearing of the pan / tilt is considered when selecting, that is, the support of the protective cover. Total weight, emergency LED lighting and temperature control and alarm devices are installed in the outer protective cover to ensure the safe operation of the instrument. The user can set multiple pre-selected observation positions for the preset pan / tilt, which is convenient for the device to work on the power equipment automatically or manually. status monitoring.

[0033] At the same time, since the infrared image does not conform to the human visual system, the monitoring device can also add a visible light camera, use the fusion technology of visible light and infrared image, through image registration and data fusion, to obtain a composite image w...

Embodiment 3

[0038] The cable shaft safety operation monitoring system and monitoring method based on network communication technology are different from Embodiment 1 or 2 in that the temperature measurement module for measuring the core temperature at the cable joint is made of bimetallic temperature measurement material, and the temperature measurement module includes The temperature-sensing bimetal, single-chip microcomputer, analog-to-digital conversion chip and signal filter device mainly express the temperature signal in the form of a current signal, and then send it to the single-chip microcomputer for sampling after filtering, amplification and analog-to-digital conversion. Since the temperature measurement module will be interfered by a lot of clutter or power frequency noise during the temperature sampling process, a low-pass filter can be set to ensure the accuracy of the signal, and then the filtered signal will be amplified to achieve subsequent processing module call.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com