Workshop following type environmental parameter monitoring system based on wireless sensor networks

A technology of wireless sensors and environmental parameters, applied in network topology, wireless communication, instruments, etc., can solve the problems of missing monitoring parameters and destroying product quality, and achieve the effect of expanding monitoring area, reducing the risk of omission, and ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

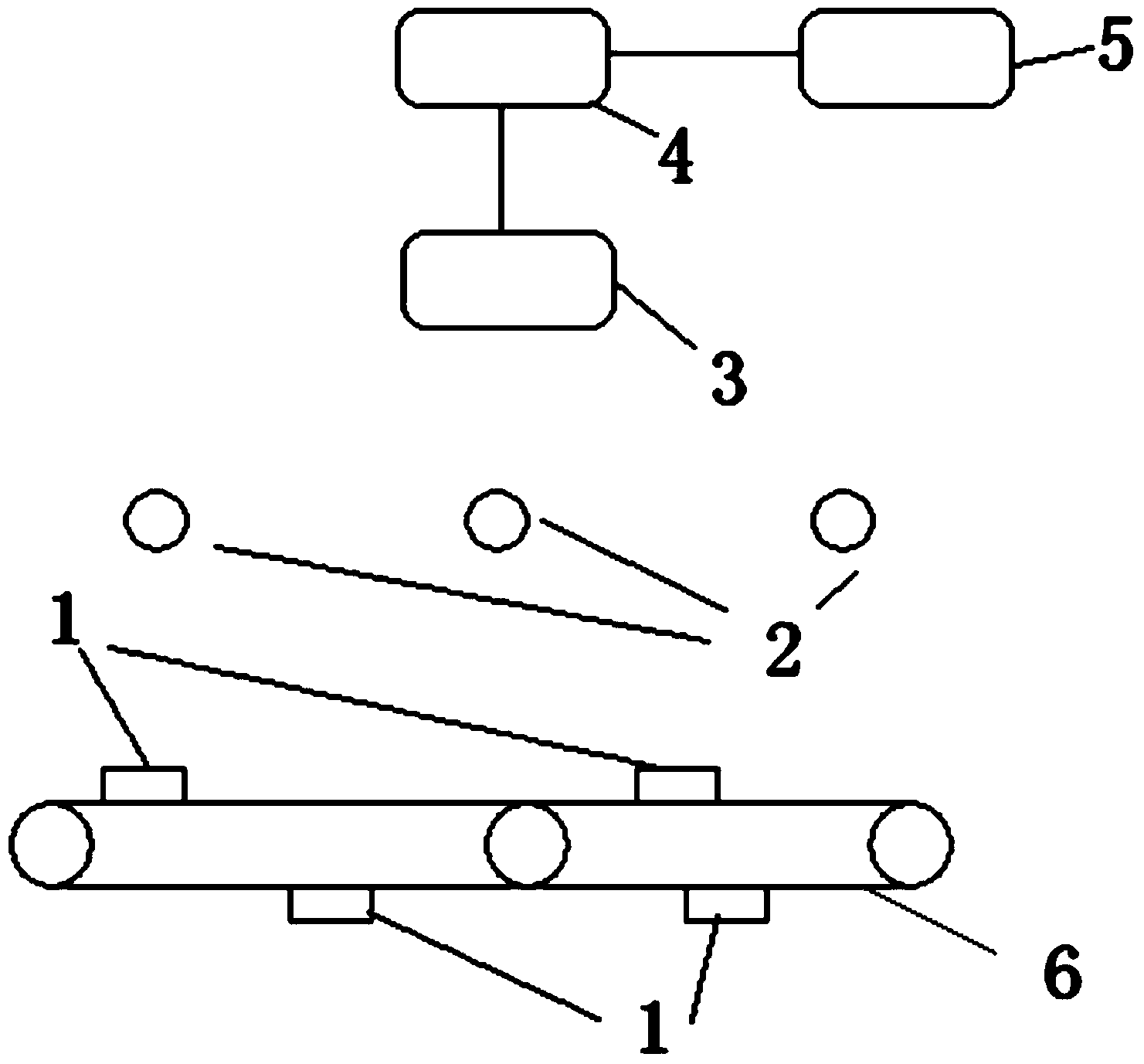

[0026] This embodiment provides a plant follow-up environmental parameter monitoring system based on a wireless sensor network, as shown in the schematic figure 1 As shown, each wireless sensor network in the system includes several sensor nodes 1 , several router nodes 2 , a coordinator node 3 , a host computer 4 and a field alarm device 5 . The sensor node 1 is installed on the conveyor belt 6 in the factory building, which can measure the ambient temperature in real time, with a monitoring accuracy of ±0.5°C and a range of -20°C-80°C; the sensor node 1 uses TDOA positioning technology, and the positioning accuracy is ±10cm; the sensor node 1 uses lithium Battery-powered, monitor once every 1 minute, if it does not exceed the allowable range, report the result every 10 times, if it exceeds, report immediately; sensor node 1 reports the result and sends data to router node 2 through the 2.4GHz low-power ZigBee wireless network , its communication distance can reach 500 meters...

Embodiment 2

[0028]This embodiment provides a plant-following environmental parameter monitoring system based on a wireless sensor network. The sensor node 1 is installed in a drug transport trolley, which can measure the ambient temperature and humidity in real time. The temperature monitoring accuracy is ±0.5°C, and the range is -20°C-80°C. ℃, humidity ±4.5%RH, range 0-100%RH (non-condensing); sensor node 1 uses MSD-MAP positioning technology, positioning accuracy ±50cm; sensor node 1 uses lithium battery power supply, monitor once every 1min, if not If it exceeds the allowable range, the result will be reported every 5 times of monitoring, and if it exceeds, it will be reported immediately; the sensor node 1 will send the data to the router node 2 through the 2.4GHz low-power ZigBee wireless network, and its communication distance can reach 300 meters (actual communication The distance is the measured distance between sensor node 1 and router node 2 in the transport trolley); router node...

Embodiment 3

[0030] This embodiment provides a plant-following environmental parameter monitoring system based on a wireless sensor network. The sensor node 1 is installed in an incubator for quick-frozen and cold food, and can measure the ambient temperature and humidity in real time. The temperature monitoring accuracy is ±0.5°C and the range is -20 ℃-80℃, humidity ±4.5%RH, range 0-100%RH (non-condensing); sensor node 1 uses MSD-MAP positioning technology, positioning accuracy ±50cm; sensor node 1 uses lithium battery power supply, sensor node 1 uses lithium Battery-powered, monitor once every 3 minutes, if it does not exceed the allowable range, report the result every 20 times, if it exceeds, report the result immediately; sensor node 1 reports the result and sends data to router node 2 through the 2.4GHz low-power ZigBee wireless network , its communication distance can reach 300 meters (the actual communication distance is the measured distance between sensor node 1 in the incubator a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com