A method for deep biological denitrification and COD removal of leachate

A technology of biological denitrification and leachate, which is applied in the field of deep biological denitrification and COD removal of leachate, can solve the problems of inability to guarantee water effluent and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

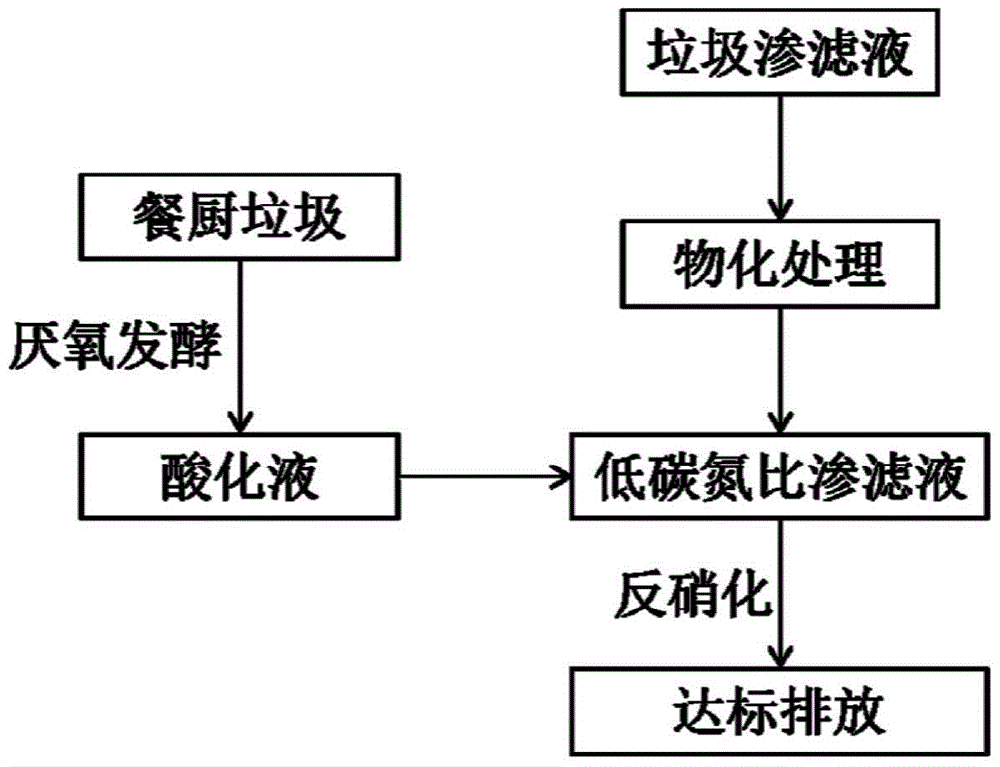

Method used

Image

Examples

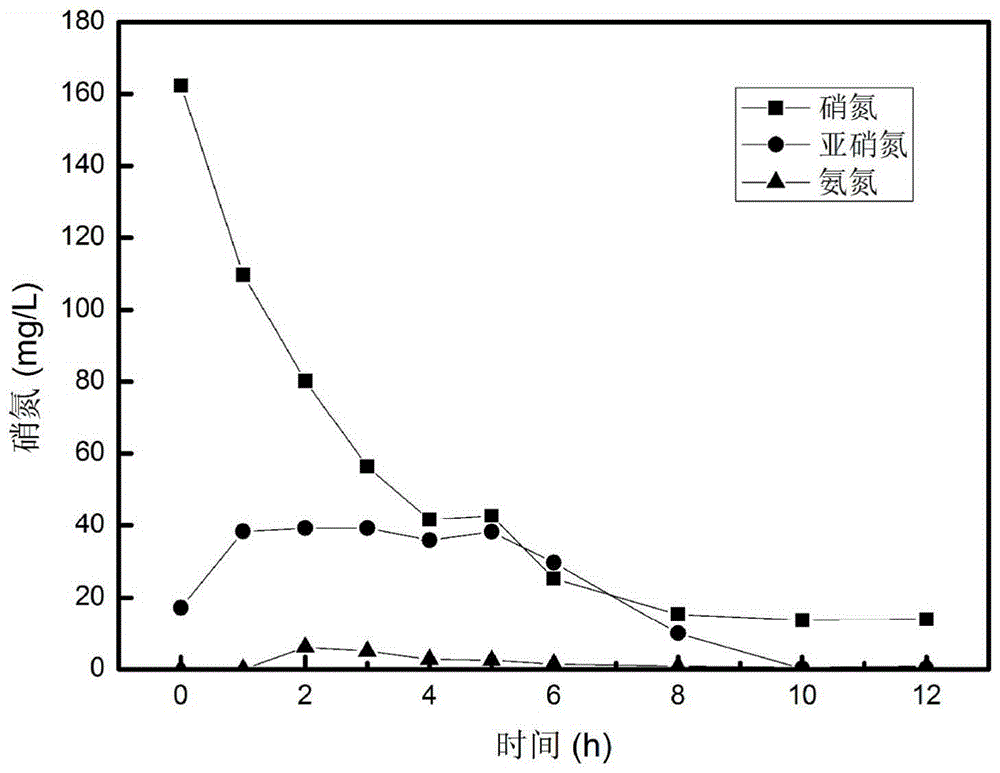

Embodiment 1

[0027] After pretreatment, the total nitrogen concentration of the leachate is about 160mg / L, most of which are nitrates, and the COD concentration is low. In the SBR reactor with an effective volume of 3L, add 35ml COD concentration of 80g / L food waste hydrolysis acidification solution, and the ratio of COD to total nitrogen is 5.8. After 12 hours of treatment, the total nitrogen concentration was below 15 mg / L, and ammonia nitrogen and nitrite nitrogen were not detected. COD effluent was 79.2mg / L.

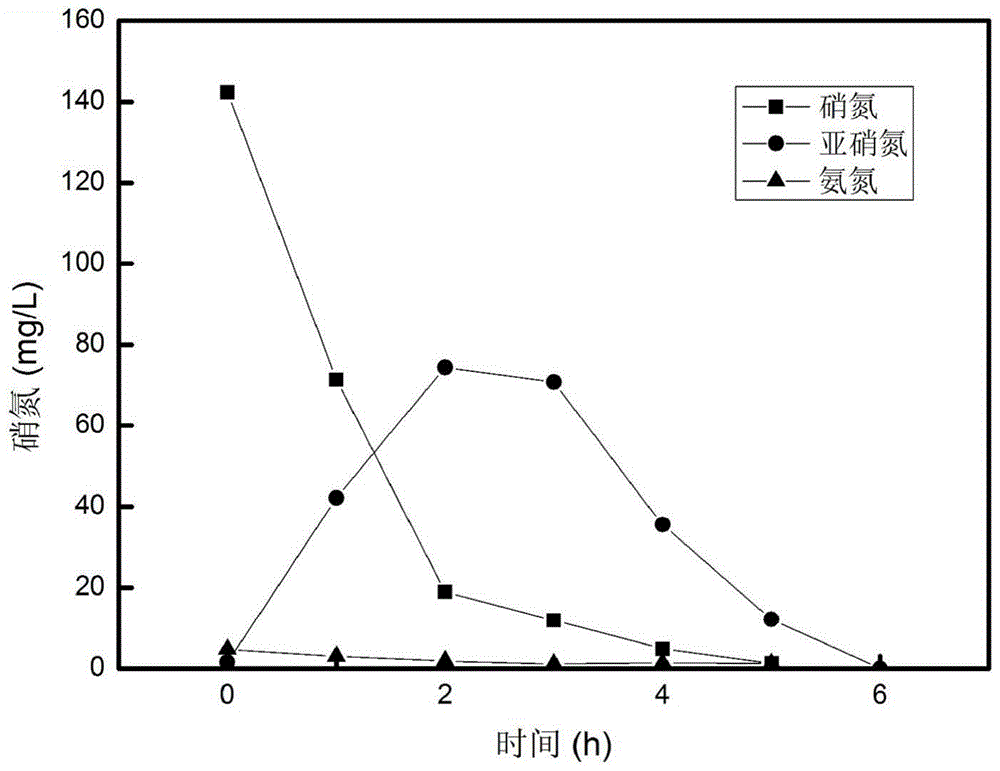

Embodiment 2

[0029] After pretreatment, the total nitrogen concentration of the leachate is about 145mg / L, most of which are nitrates, and the COD concentration is low. In the SBR reactor with an effective volume of 3L, add 28ml of food waste hydrolysis and acidification solution with a COD concentration of 80g / L, and the ratio of COD to total nitrogen is 5.1. After 6 hours of treatment, the total nitrogen concentration was below 5mg / L, and ammonia nitrogen and nitrite nitrogen were not detected.

Embodiment 3

[0031] After pretreatment, the total nitrogen concentration of the leachate is 145mg / L, most of which are nitrates, and the COD concentration is low. In the SBR reactor with an effective volume of 3L, add 38ml of food waste hydrolysis and acidification solution with a COD concentration of 80g / L, and the ratio of COD to total nitrogen is 7. After 12 hours of treatment, the total nitrogen concentration was below 15mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com