Paddy field single-side ridge building machine

A technology for building ridges and ridges, which is applied to farming machines, agricultural machinery and tools, and applications. It can solve problems such as the lack of consistency of ridges, waste of human resources, and impact on the firmness of ridges, and achieve simple and convenient rotation adjustment. Reliable, novel and reasonable structure design, saving labor resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

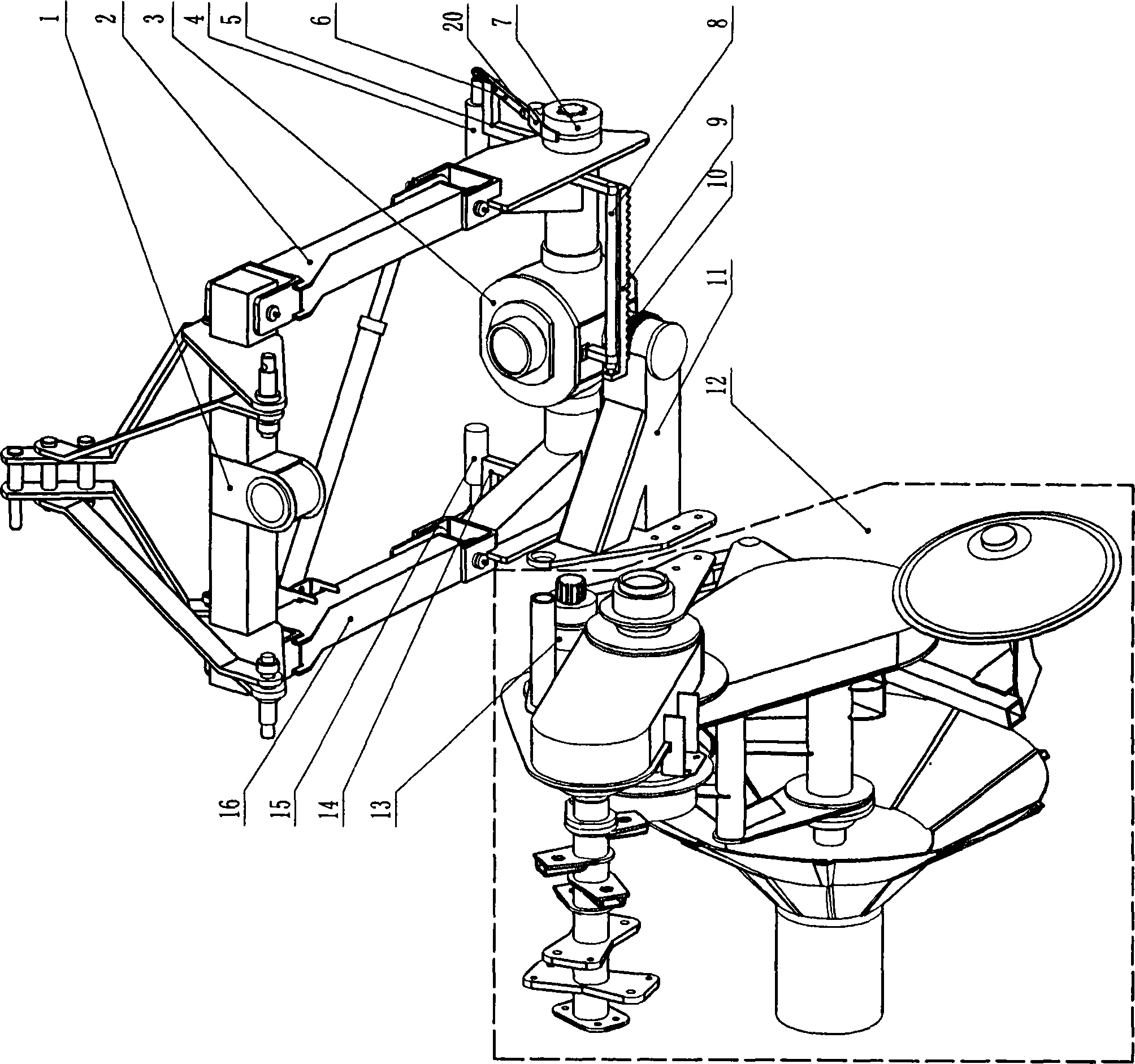

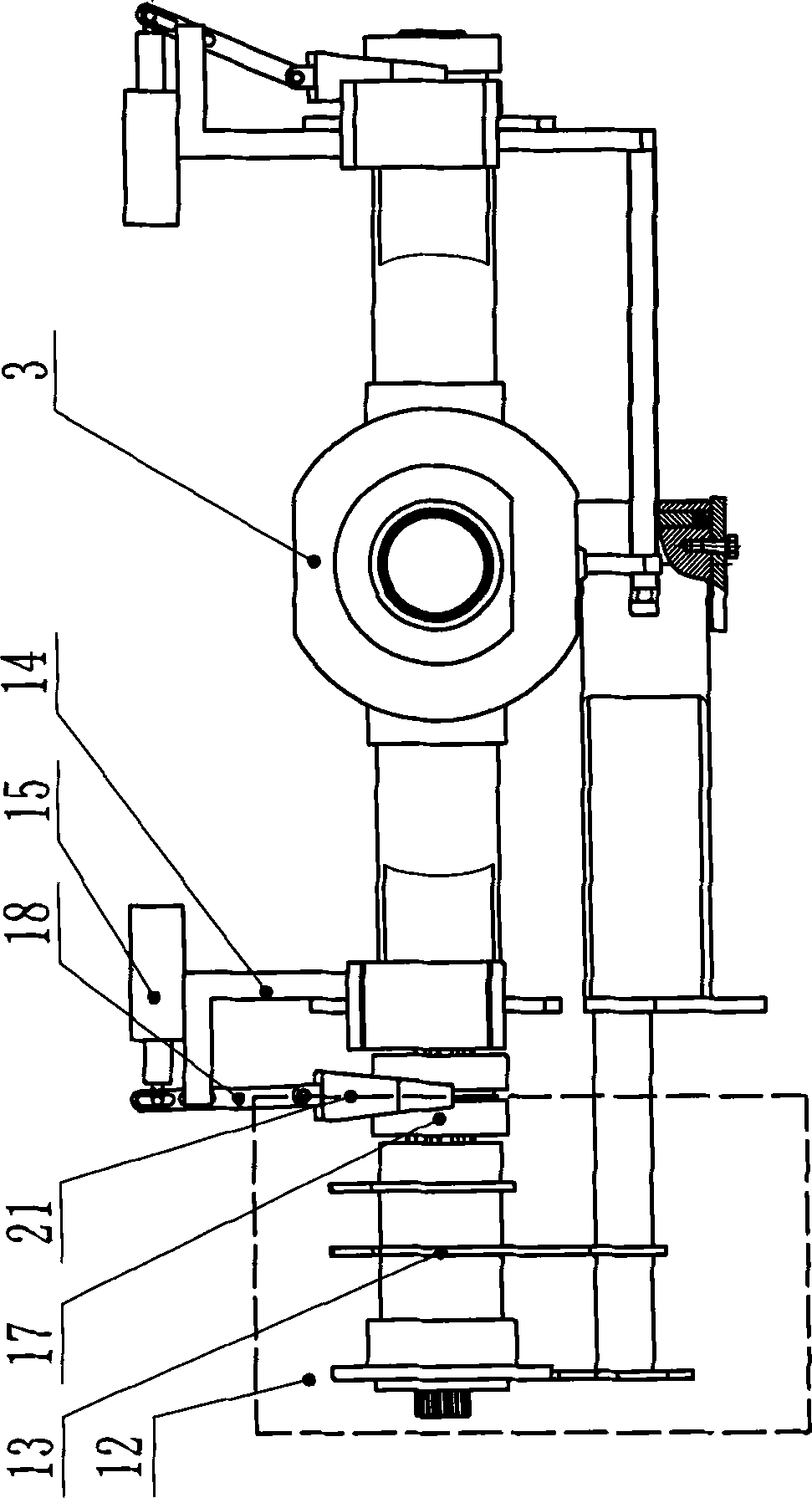

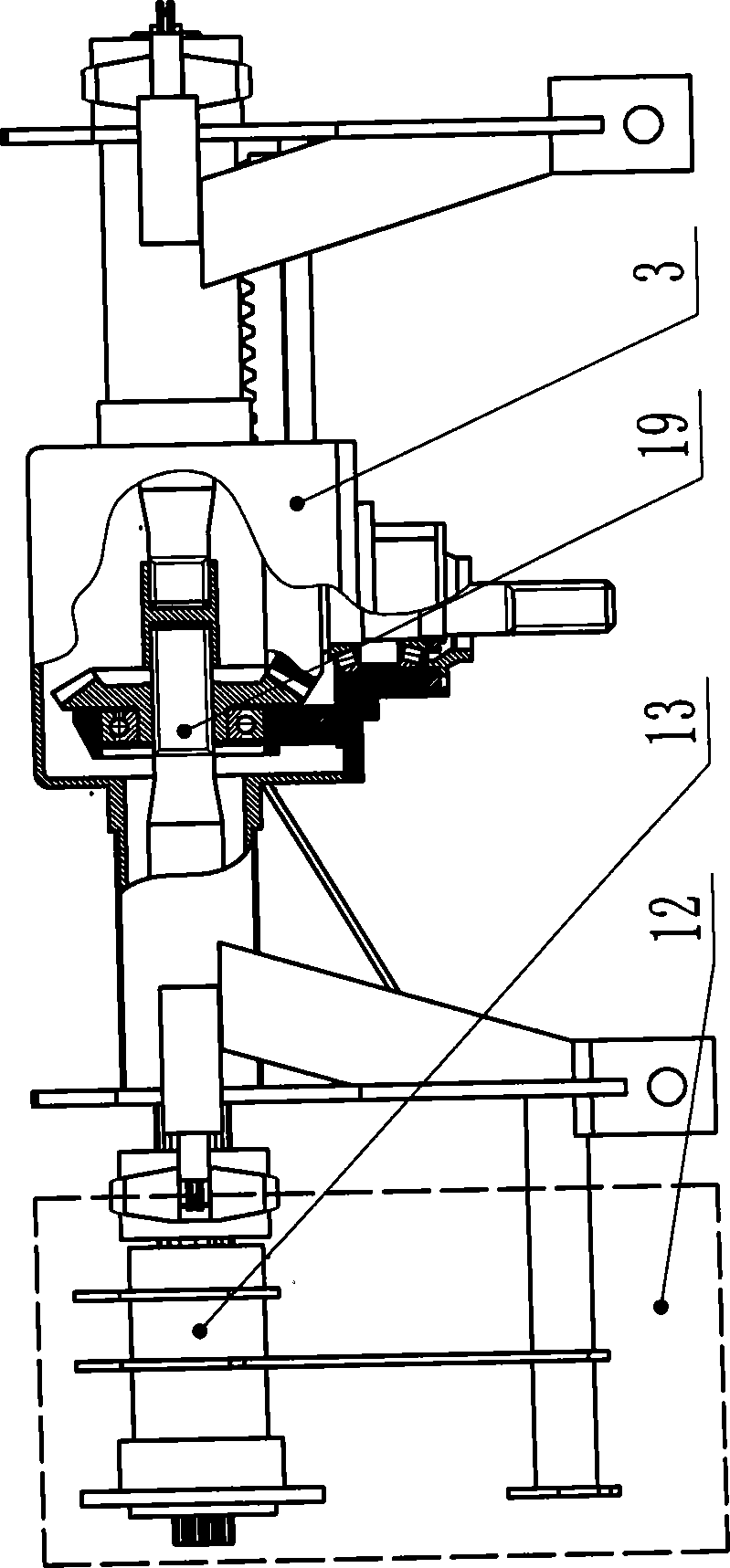

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A paddy field single-side ridge building machine includes a traction suspension frame 1 and a rotary tillage ridge construction operation assembly 12, and a left longitudinal beam 16 and a right longitudinal beam 2 are hingedly installed on the left and right sides of the traction suspension frame 1 respectively. On the left longitudinal beam 16 and the right longitudinal beam 2, between the left and right longitudinal beams 16 and 2, a double bevel gear reversing gearbox 3 is supported and installed, and on the left and right sides of the double bevel gear reversing gearbox 3 The left bracket 14 and the right bracket 5 are respectively mounted symmetrically on the upper part, and the left two-way driving oil cylinder 15 and the right two-way driving oil cylinder 4 are respectively fitted on the left bracket 14 and the right bracket 5 symmetrically, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap