Longitudinal extrusion forming high-pressure grouting device and high-pressure grouting production technique thereof

A high-pressure grouting and extrusion molding technology, used in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems affecting the occupational health and safety of operators, difficult to guarantee product quality, and occupational diseases of operators, so as to eliminate occupational diseases. , The performance of the whole machine is reliable, and the effect of reducing labor and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

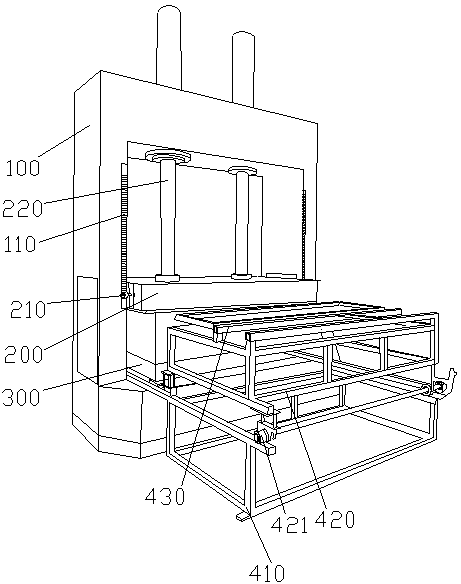

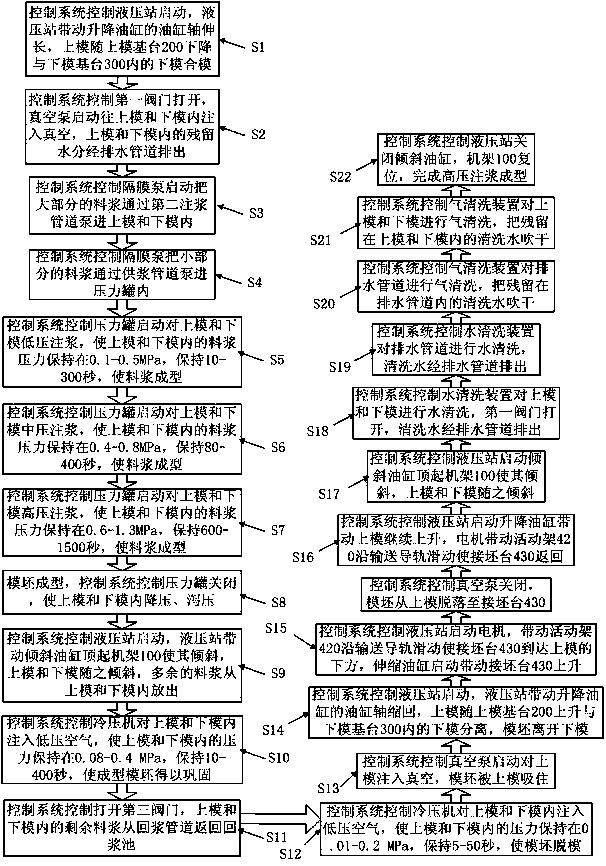

[0043] Such as figure 1 As shown, the high-pressure grouting equipment for longitudinal extrusion molding includes a frame 100, an upper mold abutment 200, an upper mold, a lower mold abutment 300, a lower mold, a pressure tank, a vacuum pump, a hydraulic station, a blanking machine, a motor, Lifting oil cylinder, tilting oil cylinder, telescopic oil cylinder, diaphragm pump, cold press and control system, the lifting guide rail 110 is arranged on the frame 100, the lifting pulley 210 is arranged on the upper mold base 200, and the upper mold base 200 passes through the guide The column 220 is connected to the top of the frame 100, the upper mold is fixed in the upper mold base 200, the lifting cylinder is connected with the upper mold b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com