Anti-thunder detection automatic wind-up device

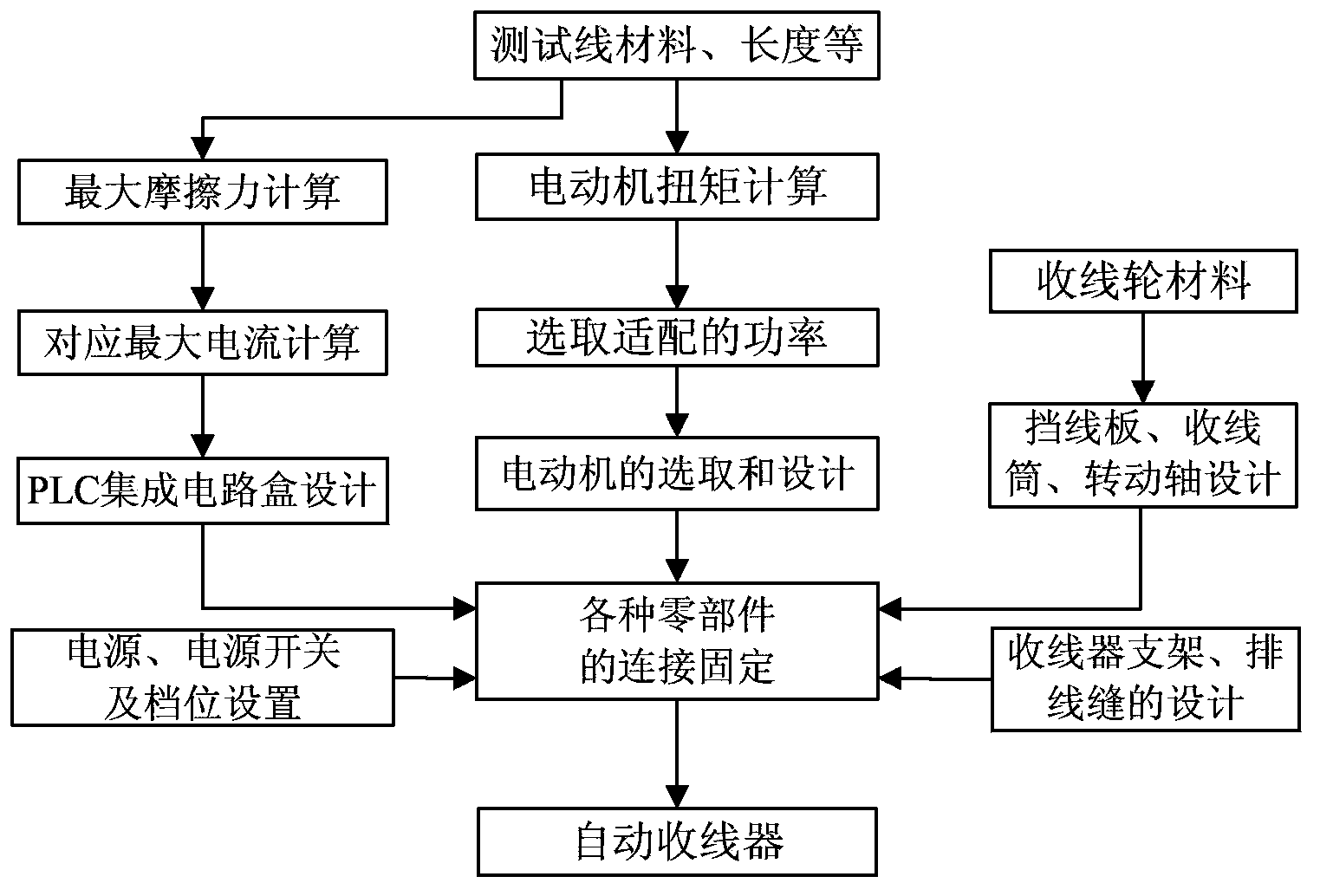

A wire take-up device and automatic detection technology, which is applied in the field of wire take-ups, can solve problems such as unsuitable for lightning protection detection work, automatic shutdown without setting, and foreign objects on the line without setting, so as to improve the efficiency of lightning protection detection and change time-consuming Effortless, easy-to-carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

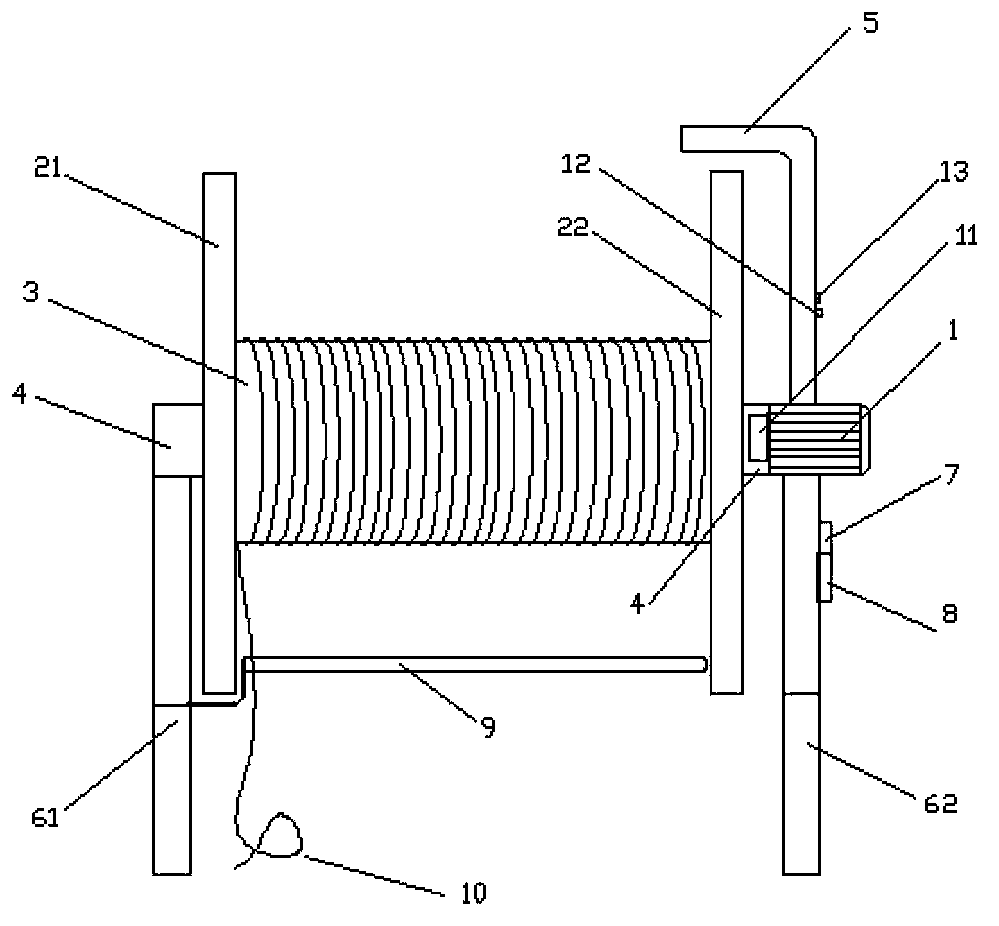

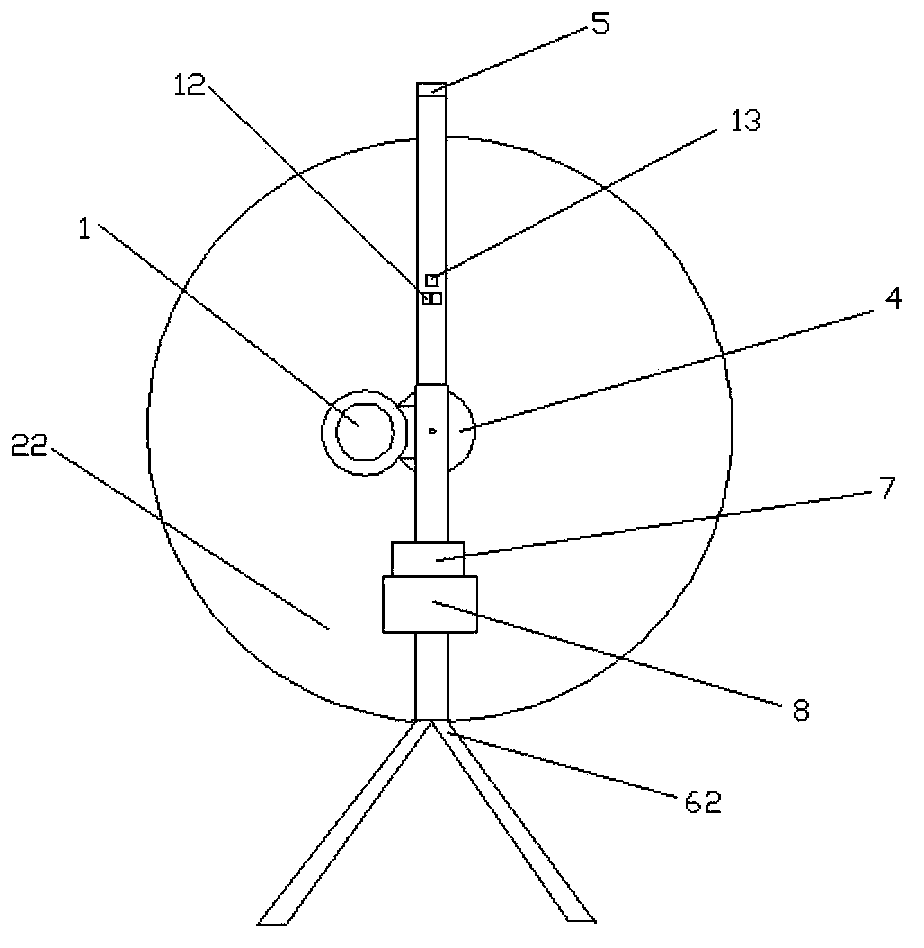

[0027] An automatic take-up device, such as figure 1 Said, including the first support 61, the second support 62, between the first support 61 and the second support 62, the take-up reel 3 and the take-up reel rotating shaft 4 are housed; A wire blocking plate 21 and a second wire blocking plate 22 . The motor 1 is fixed on the second bracket 62, and the take-up spool rotating shaft 4 and the motor rotating shaft 11 are connected together to form an integral body through a gear connection, wherein a PLC integrated circuit box 7 is also installed on the second bracket 62, and the PLC integrated The circuit box 7 is electrically connected to the motor 1 .

[0028] In lightning protection testing, many on-site environments are relatively complex, and there are many other equipment on site (such as fans on the roof, outdoor units of air conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com