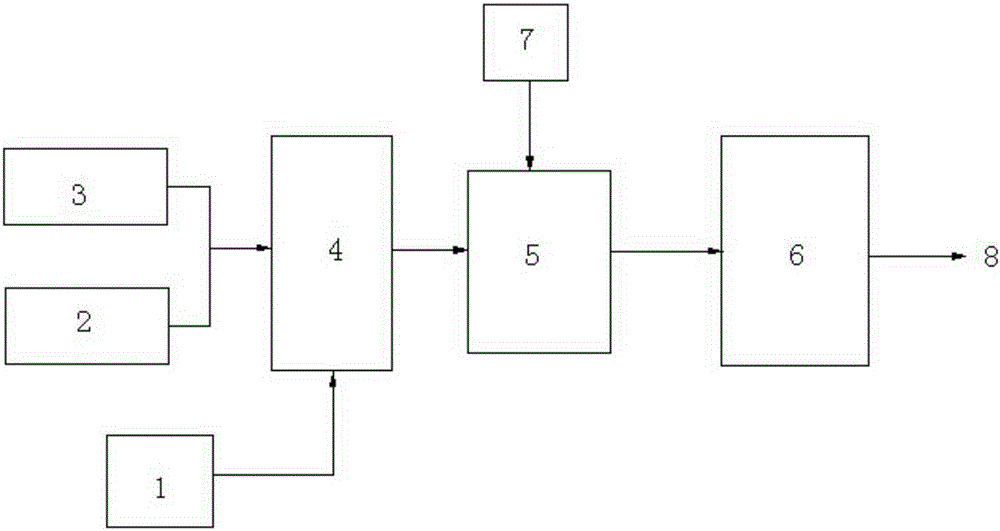

A method for microwave-enhanced iron-carbon combined with microwave oxidation to treat oily wastewater

A microwave catalytic oxidation, iron-carbon technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as ineffective COD removal and failure to meet national oily wastewater discharge standards , to achieve the effect of improving microwave utilization, shortening reaction time and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the process of the present invention, a certain oily wastewater is processed, and the reaction conditions are as follows: first, the iron-carbon is pretreated: the first step is to rinse the activated carbon with tap water for 4 hours, and after rinsing, the activated carbon is dried and sealed; Soak in oily wastewater for 30 minutes, first make the adsorption of pollutants by activated carbon reach saturation, and then use industrial alkali and dilute hydrochloric acid to clean the oil stains and oxides adhering to the surface of iron filings in sequence, then wash them with tap water, dry them, and seal them for later use. use; then, mix the pretreated iron-carbon at 8:2, add 25% of the waste water into the waste water after mixing, pH 2.5, microwave output power 400W, reaction time 8 minutes; In the medicine separation and precipitation process, the aluminum-iron composite flocculant and polymer flocculant are added according to the wastewater volume of 0...

Embodiment 2

[0032] According to the flow process of the present invention, a certain oily wastewater is processed, and the reaction conditions are as follows: first, the iron carbon is pretreated: the first step is to rinse the activated carbon with tap water for 4 hours to prevent the interference of carbon black and other impurities, and dry the activated carbon after washing , seal; treat waste water with relevant oily waste water before use for 30 minutes, first make the adsorption of activated carbon on pollutants reach saturation, the second step is to clean the oil and oxides adhering to the surface of iron filings with industrial alkali and dilute hydrochloric acid in turn, and then use Wash with tap water, dry, and seal for use; then, mix the pretreated iron-carbon at 9:1, add 20% of the waste water into the waste water after mixing, pH 2.5, microwave output power 450W, The reaction time is 10 minutes; the microwave effluent enters the dosing separation and precipitation process, ...

Embodiment 3

[0036] According to the process of the present invention, a certain oily wastewater is processed, and the reaction conditions are as follows: first, the iron-carbon is pretreated: the first step is to rinse the activated carbon with tap water for 4 hours, and after rinsing, the activated carbon is dried and sealed; Soak in oily wastewater for 30 minutes, first make the adsorption of pollutants by activated carbon reach saturation, and then use industrial alkali and dilute hydrochloric acid to clean the oil stains and oxides adhering to the surface of iron filings in sequence, then wash them with tap water, dry them, and seal them for later use. use; then, mix the pretreated iron-carbon according to 8.5:1.5, and add 30% of the waste water into the waste water after mixing, pH 2, microwave output power 500W, reaction time 15 minutes; microwave effluent enters dosing separation In the sedimentation process, the aluminum-iron composite flocculant and polymer flocculant are added ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com