Epoxy resin composition and reactive type flame retardant thereof

A technology of reactive flame retardants and epoxy resins, applied in the direction of phosphorus organic compounds, etc., can solve problems such as heat generation, fire hazards, and inability to effectively export light, and achieve the best light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

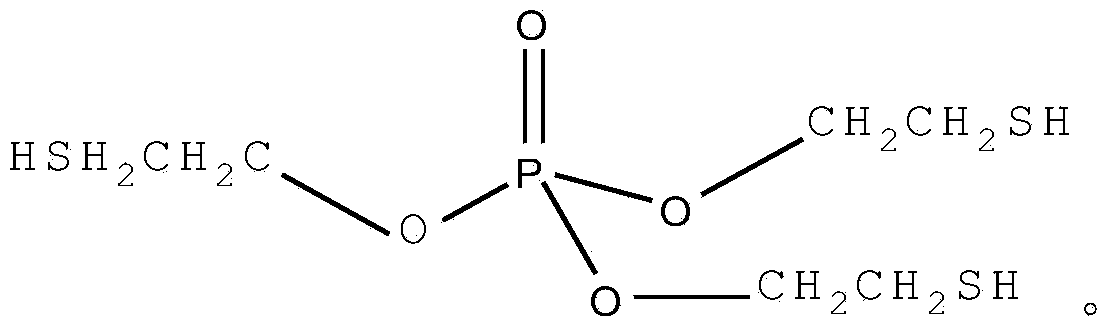

[0028] Embodiment 1: Sodium hydrosulfide method prepares trimercapto ethyl phosphate (A)

[0029] Add 9g (0.03mol) of trichloroethyl phosphate to the three-necked flask, and add 100ml of sodium hydrosulfide aqueous solution (about 0.9mol / L) dropwise therein under the stirring environment of 300r / min, react at constant temperature for 3h, then cool down to room temperature. Extract with 30ml of chloroform, fractionate the extract (chloroform and product) under reduced pressure, and separate the chloroform to obtain trimercaptoethyl phosphate.

Embodiment 2

[0030] Embodiment 2: Sodium hydrosulfide method prepares trimercapto ethyl phosphate (B)

[0031] Add 9 g (0.03 mol) of trichloroethyl phosphate to the three-necked flask, and add 100 ml of sodium hydrosulfide aqueous solution (about 1.5 mol / L) dropwise therein under a stirring environment of 300 r / min, react at constant temperature for 3 h, and then cool down to room temperature. Extract with 30ml of chloroform, fractionate the extract (chloroform and product) under reduced pressure, and separate the chloroform to obtain trimercaptoethyl phosphate.

Embodiment 3

[0032] Embodiment 3: sodium hydrosulfide method prepares trimercapto ethyl phosphate (C)

[0033] Add 9 g (0.03 mol) of trichloroethyl phosphate to the three-necked flask, and add 100 ml of sodium hydrosulfide aqueous solution (about 2.1 mol / L) dropwise therein under a stirring environment of 300 r / min, react at constant temperature for 3 h, and then cool down to room temperature. Extract with 30ml of chloroform, fractionate the extract (chloroform and product) under reduced pressure, and separate the chloroform to obtain trimercaptoethyl phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com