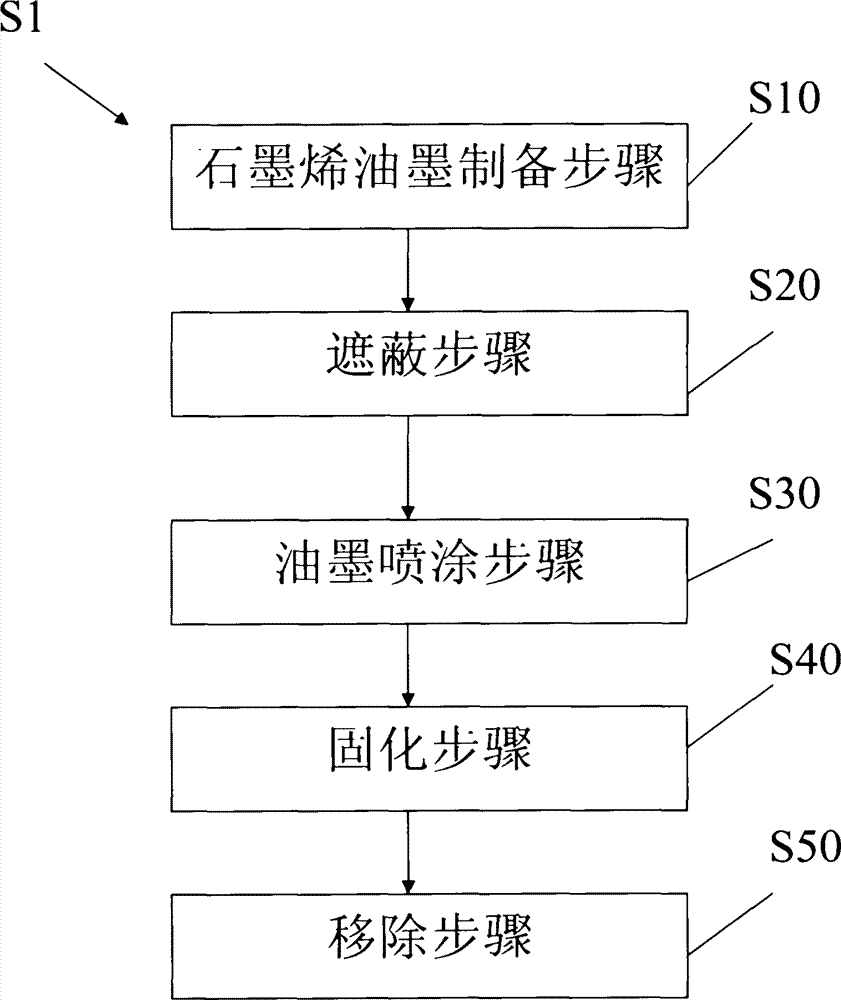

Graphene ink and method for manufacturing graphene pattern using the same

A technology of graphene and graphene sheets, which is applied in ink, household utensils, conductive pattern formation, etc., and can solve problems such as difficult to exert characteristics, bulky size, and negative effects of derivative products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in more detail in conjunction with the drawings and component symbols below, so that those skilled in the art can implement it after studying this specification.

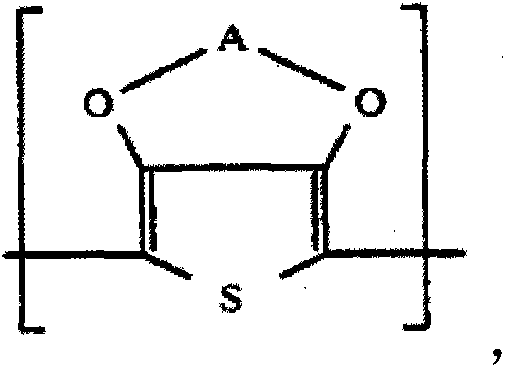

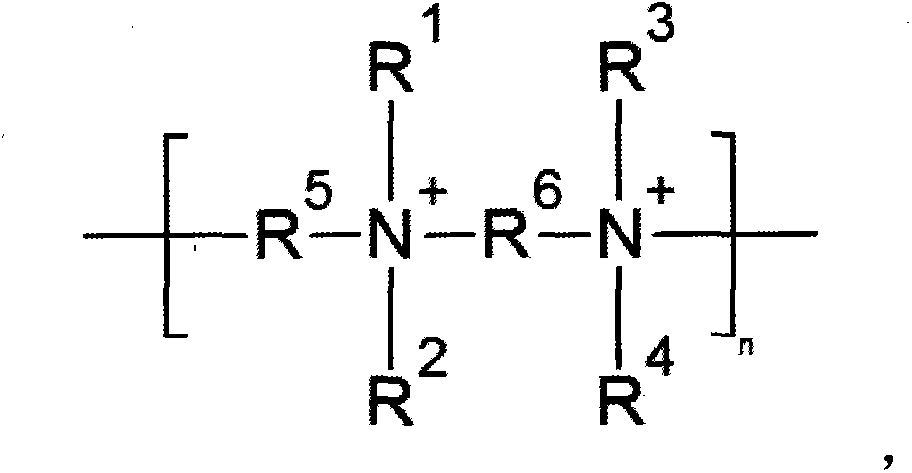

[0018] The graphene ink provided by the present invention includes: a dispersion solution, a polymer binder, and a plurality of graphene sheets, the dispersion solution accounts for more than 99wt% of the graphene ink, and contains at least one solvent, so that the dispersion The surface tension of the solvent is between 35mJ / m2 and 55mJ / m2; the polymer binder is dissolved in the dispersion solution to form a colloidal solution together, and the polymer binder accounts for 0.01-0.5wt% of the graphene ink ; The graphene sheet is fully dispersed in the colloidal solution, and the suspension concentration of the graphene sheet accounts for about 0.1-5wt% of the graphene ink, wherein the viscosity of the graphene ink is less than 100cp, and its surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com