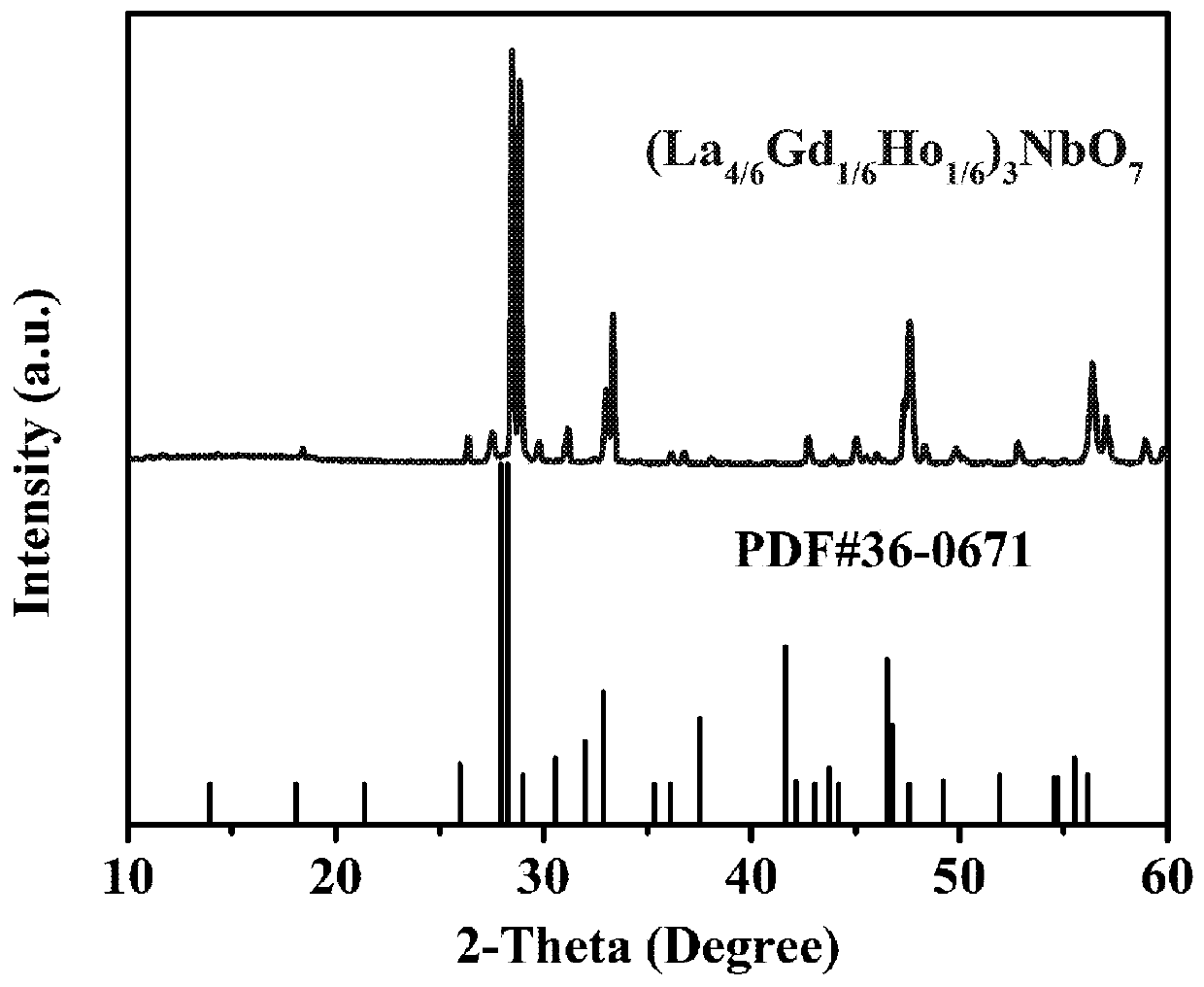

Three-rare-earth niobate ceramic and preparation method thereof

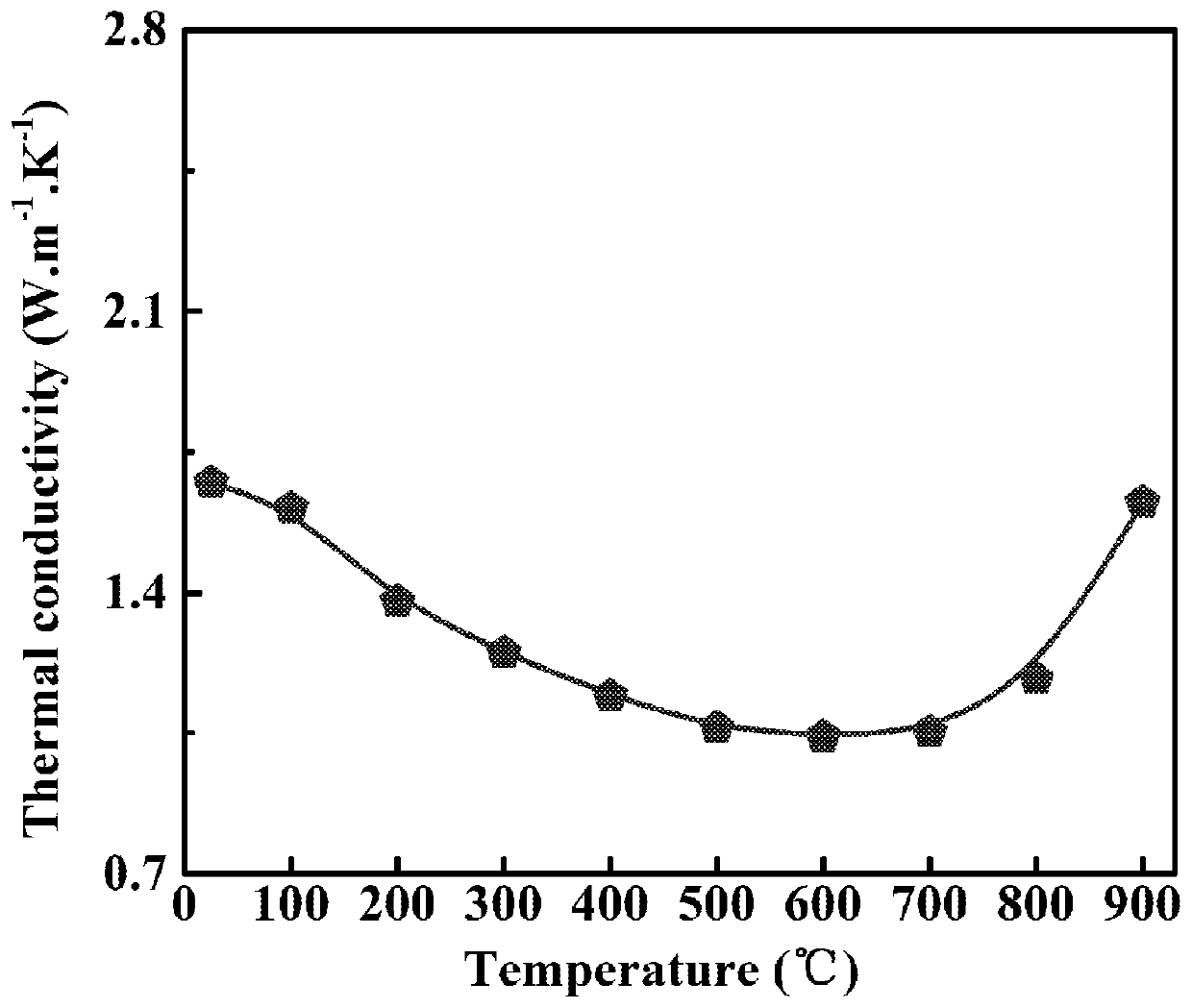

A niobate and ceramic technology, applied in the field of three rare earth niobate ceramics and their preparation, can solve the problem of high thermal conductivity, achieve the effects of low thermal conductivity, reduced thermal mismatch stress, and high thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the above-mentioned three rare earth niobate ceramics comprises the following steps:

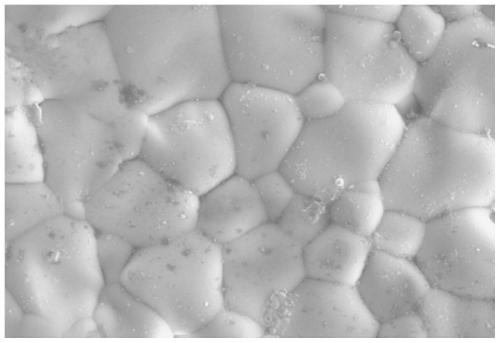

[0050] Step (1): Weigh La with a molar ratio of La:Gd:Ho:Nb of 3(1-x-y):3x:3y:1 (02 o 3 Powder, Gd 2 o 3 Powder, Ho 2 o 3 Powder and Nb 2 o 5 Powder, add distilled water or ethanol solvent for mixing, then add sintering aid TiO 2 Powder and ZrO 2 powder, where TiO 2 The molar mass of the powder is Nb 2 o 5 0.01 to 0.05 times the molar weight of the powder, ZrO 2 The molar mass of the powder is Nb 2 o 5 0.04 to 0.1 times the molar weight of the powder, and the above six powders (La 2 o 3 Powder, Gd 2 o 3 Powder, Ho 2 o 3 Powder, Nb 2 o 5 Powder, TiO 2 Powder and ZrO 2 The molar ratio of powder) to solvent is (3:1)~(5:1), and the grinder is used for grinding, and the powder A is obtained after drying; the grinder adopts a vertical laboratory sand mill, the model is WT0.3 , the grinding time is 24~48h, the speed of the grinder is 2000~3000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com