Wool leather fatliquoring agent and preparation method thereof

A fatliquoring agent and wool leather technology, applied in the field of wool leather fatliquor and its preparation, can solve the problems of the fatliquoring agent absorption effect (low absorption rate, waste of raw materials, environmental pollution, increasing the amount of the fatliquor, etc.) Smooth and moist hand, light leather color, good fatliquoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

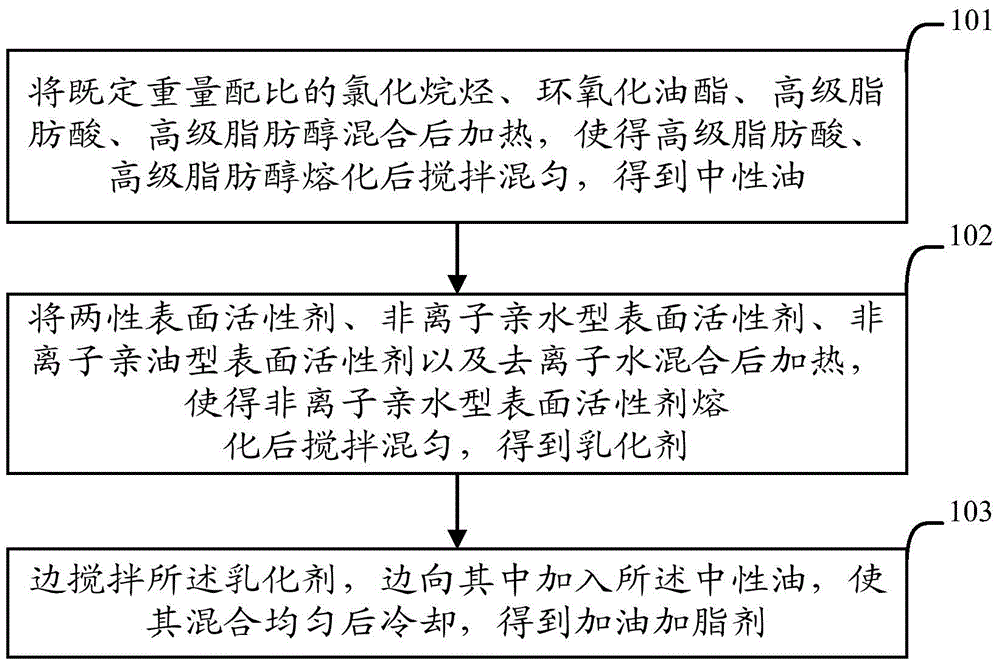

Method used

Image

Examples

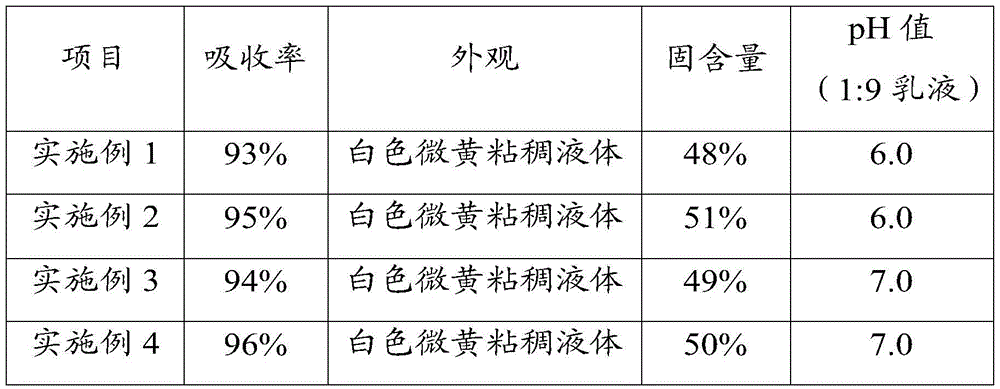

Embodiment 1

[0059] The wool leather fatliquoring agent provided by the embodiment of the present invention, according to parts by weight, its components include: 70 parts of neutral oil and 15 parts of emulsifier;

[0060] In neutral oil, by weight percentage: 8% chlorinated alkanes, 70% epoxidized oil esters, 22% higher fatty acids and higher fatty alcohols;

[0061] Chlorinated alkanes: composed of 25%-32% chlorine-containing synthetic cowshoe oil and 42-degree chlorinated paraffin in a weight ratio of 4:1; epoxidized oil esters: composed of epoxidized fatty acid methyl ester and epoxidized three Fatty acid glycerides are composed at a weight ratio of 4:1; higher fatty acids and higher fatty alcohols are equal in weight;

[0062] In the emulsifier, by weight percentage, it includes 50% of amphoteric surfactant, 20% of nonionic hydrophilic surfactant, and 30% of nonionic lipophilic surfactant;

[0063] More specifically, the higher fatty acid is: n-dodecanoic acid;

[0064] Higher fatt...

Embodiment 2

[0078] The wool leather fatliquoring agent provided by the embodiment of the present invention, according to parts by weight, its components include: 85 parts of neutral oil and 30 parts of emulsifier;

[0079] In neutral oil, by weight percentage: chlorinated alkanes 12%, epoxidized oil esters 65%, higher fatty acids and higher fatty alcohols 23%;

[0080] Chlorinated alkanes: composed of synthetic cowshoe oil containing 25%-32% chlorine and 42-degree chlorinated paraffin in a weight ratio of 7:3;

[0081] Epoxidized oil ester: composed of epoxidized fatty acid methyl ester and epoxidized triglyceride fatty acid in a weight ratio of 7:3;

[0082] Higher fatty acid and higher fatty alcohol equal weight;

[0083] In the emulsifier, by weight percentage, it includes 70% of amphoteric surfactant, 10% of nonionic hydrophilic surfactant, and 30% of nonionic lipophilic surfactant;

[0084] More specifically, the higher fatty acid is: n-dodecanoic acid;

[0085] Higher fatty alcoh...

experiment example 3

[0099] The wool leather fatliquoring agent provided by the embodiment of the present invention, in parts by weight, its components include: 77 parts of neutral oil and 23 parts of emulsifier;

[0100] In neutral oil, by weight percentage: chlorinated alkanes 8%, epoxidized oil esters 75%, higher fatty acids and higher fatty alcohols 17%;

[0101] Chlorinated alkanes: composed of synthetic cowshoe oil containing 25%-32% chlorine and 42-degree chlorinated paraffin in a weight ratio of 9:1;

[0102] Epoxidized oil ester: composed of epoxidized fatty acid methyl ester and epoxidized triglyceride fatty acid in a weight ratio of 9:1;

[0103] Higher fatty acid and higher fatty alcohol equal weight;

[0104] In the emulsifier, by weight percentage, it includes 60% of amphoteric surfactant, 15% of nonionic hydrophilic surfactant, and 25% of nonionic lipophilic surfactant;

[0105] More specifically, the higher fatty acid is: n-hexadecanoic acid;

[0106] Higher fatty alcohol: n-hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com