Manufacturing process of permeable bricks capable of absorbing waste gas and permeable bricks produced by this process

A manufacturing process and a technology for absorbing waste gas, which is applied to pavements paved with prefabricated blocks, pavement details, buildings, etc., can solve problems such as high air pollution index, inability to plant a large number of green plants, poor self-purification ability of cities, etc., to improve decontamination Bacterial ability, mitigation of heat island effect, and stable contact mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

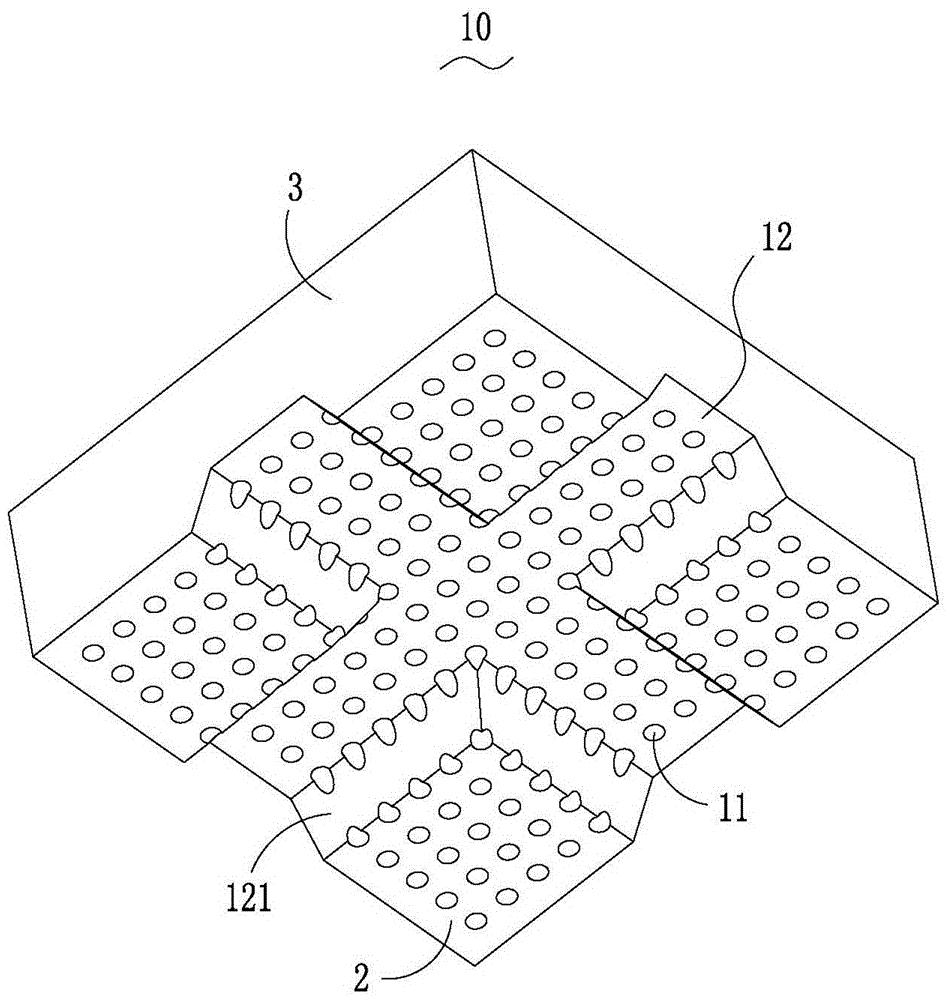

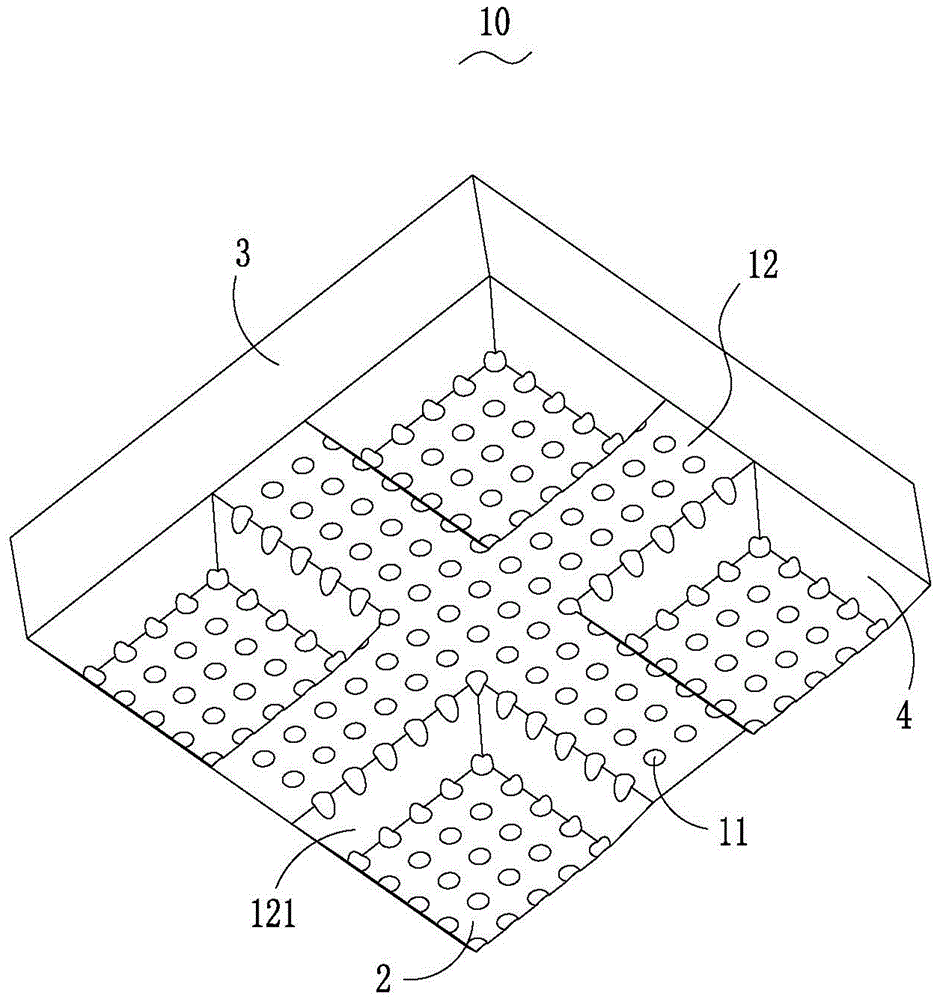

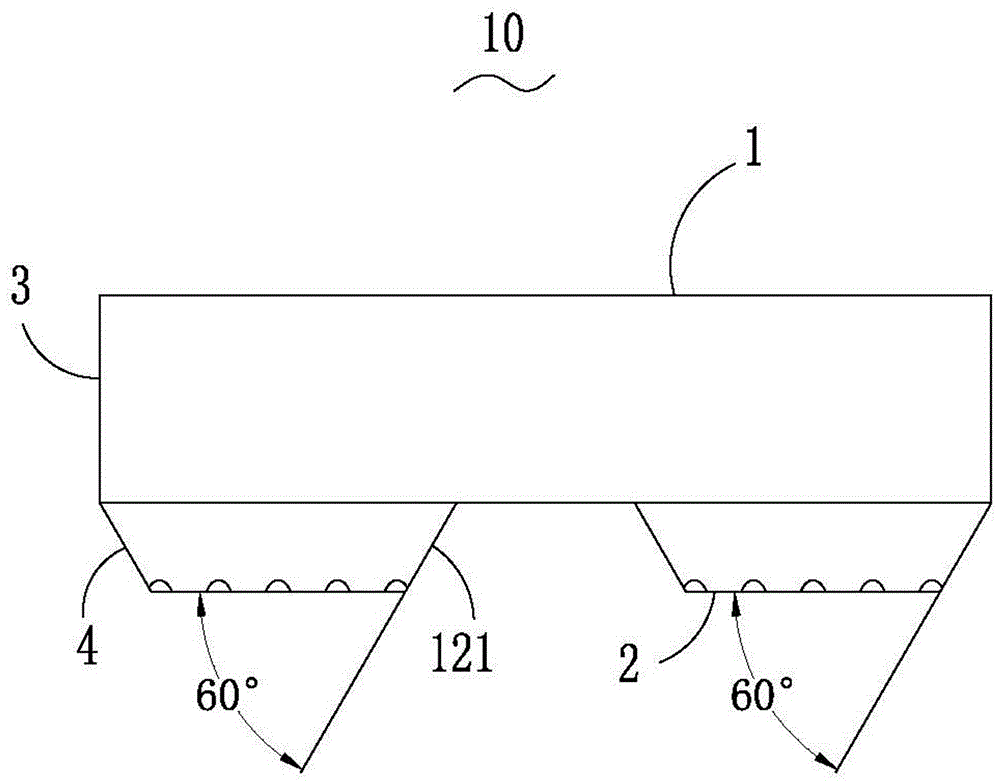

[0029] The following will combine the attached Figures 1 to 5 And the preferred embodiment is a more detailed description of the manufacturing process of a permeable brick capable of absorbing waste gas proposed by the present invention and the permeable brick produced by this process.

[0030] The invention provides a manufacturing process of a permeable brick capable of absorbing waste gas, which comprises the following steps:

[0031] 1. To make the bottom material, mix Portland cement, sandstone with a particle size of 3-8mm and activated carbon with clean water and stir evenly, and pour it into the molding machine as the base material of the permeable brick. The weight parts of each material for making the bottom material do not contain water The ratio is: Portland cement 330-380 parts, sand and gravel 1950-2050 parts, activated carbon 12-14 parts;

[0032] 2. To manufacture fabrics, mix Portland cement, sandstone with a particle size of 3-8mm, zinc oxide, diatomaceous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com