Wind-resistance spherical supporting base of novel structure

A technology of wind-resistant bearings and new structures, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of plane friction pairs that are prone to failure, bulky and bulky structures, and short service life of wind-resistant bearings, and achieve stable and uniform load transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

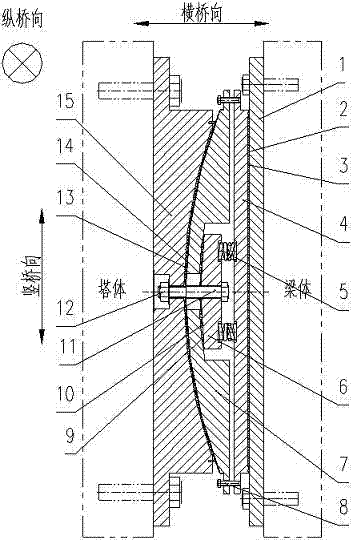

[0018] The present invention is illustrated with reference to the accompanying drawings and the given examples.

[0019] Such as figure 1As shown, a new type of wind-resistant support, the support has seat plate III (6), seat plate IV (7) and seat plate V (15); the seat plate IV (7) is a One side is an arc-shaped spherical surface, and the other side is a flat cylindrical steel plate; the middle part of the seat plate IV (7) has a groove; the bottom surface of the groove in the middle part of the seat plate IV (7) is an arc-shaped spherical The arc-shaped spherical surface on one side is concentric; the seat plate III (6) is a cylindrical steel plate with an arc-shaped spherical surface on one side and a plane on the other side, and the seat plate III (6) is located on the seat plate IV (7) In the middle groove, one side of the arc-shaped spherical surface of the seat plate III (6) fits closely with the bottom surface of the middle groove of the seat plate IV (7); the spheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com