Hopper type material distribution device for sealed calcium carbide furnace and automatic control method

A material distribution device, calcium carbide furnace technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of harsh site environment, physical and mental health effects, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

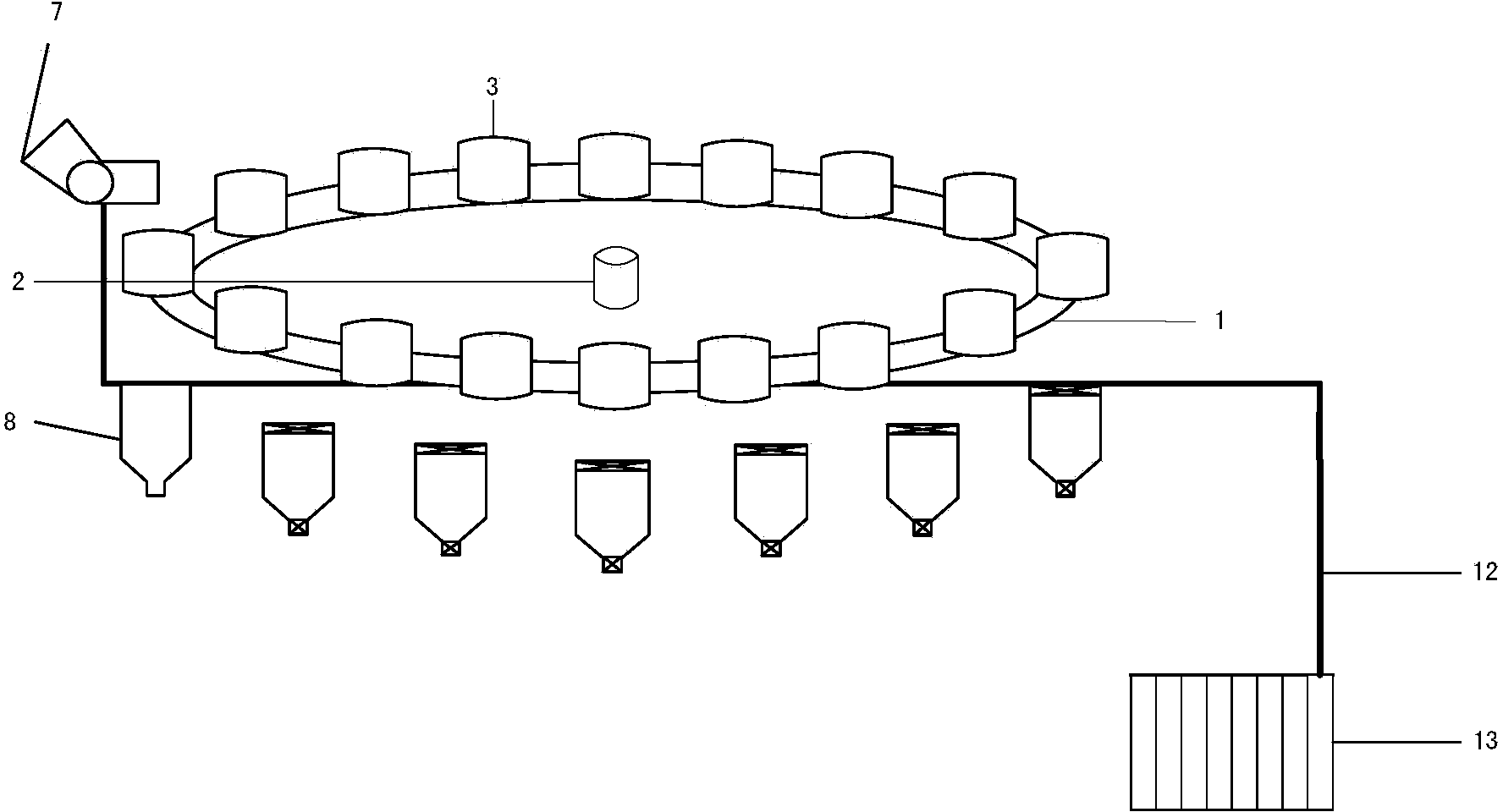

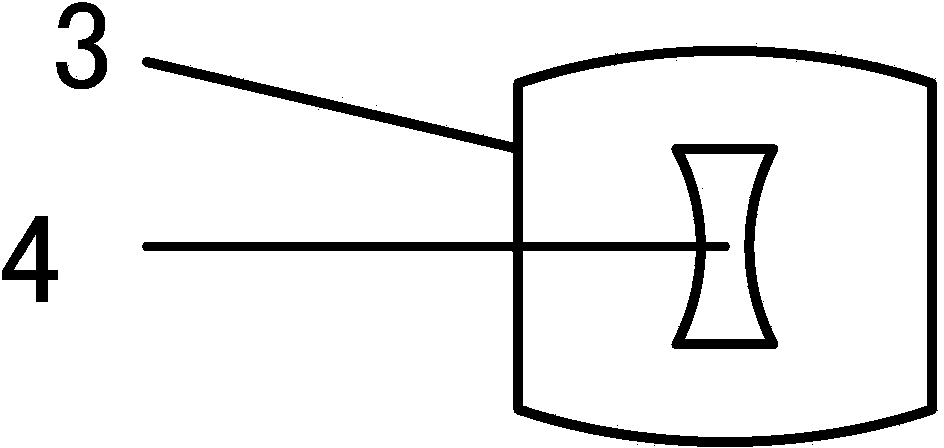

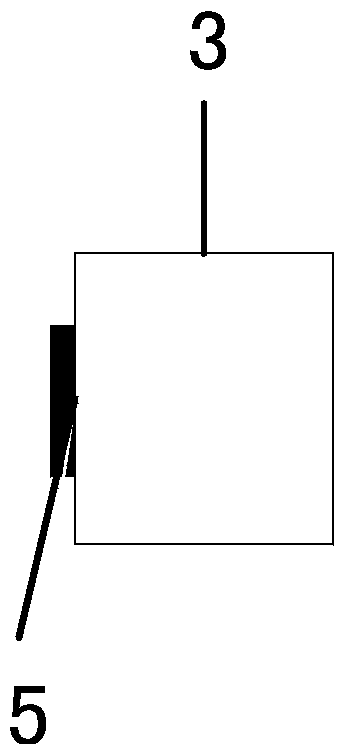

[0034] Such as figure 1 As shown, the hopper-type automatic distributing device for a closed calcium carbide furnace of the present invention includes an annular rotating device 1 on which an AC motor 2 is installed, and the AC motor 2 can be used to automatically control the start-up of the annular rotating device 1 Stop and rotate speed, also be fixed with several storage hoppers 3 that can turn over automatically on the annular rotating device 1.

[0035] The method for realizing its flipping is: a hydraulic cylinder connected to the bottom of the storage hopper 3 is installed at the bottom of the storage hopper 3 close to the center of the ring rotation device 1, and the bottom of the storage hopper 3 is away from the center of the ring rotation device 1 through the rotating shaft. When the storage hopper 3 needs to be turned over, the PLC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com