A method for automatic detection of spring performance of railway vehicle brake valve

A railway vehicle, automatic detection technology, applied in the direction of elastic testing, measuring device, testing of mechanical parts, etc., can solve the problems of large error in test results, inconvenient data, and many human factors, so as to facilitate data management and eliminate human factors. factors, the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

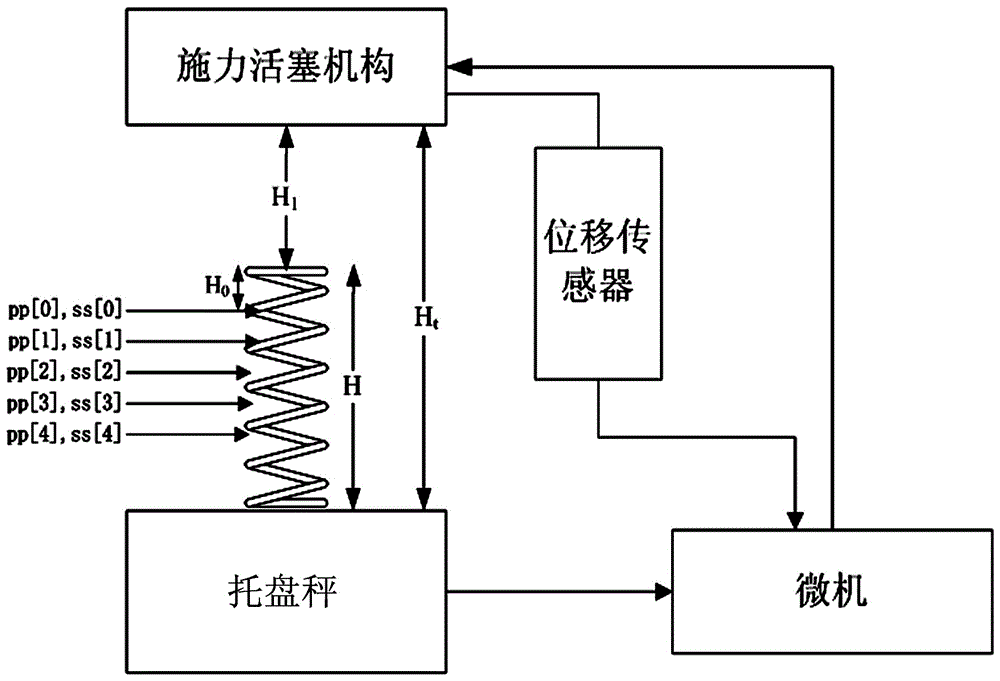

[0027] A method for automatically detecting spring performance of a railway vehicle brake valve, the method is realized by the following steps:

[0028] a. Select a pallet scale, a force-applying piston mechanism, a displacement sensor, and a microcomputer; the force-applying piston mechanism includes a piston that can reciprocate up and down, and a stepping motor for driving the piston; install the piston on the pallet Above the scale, install the displacement sensor on the output shaft of the stepping motor, connect the signal output end of the pallet scale, the signal output end of the displacement sensor, and the signal input end of the stepping motor to the microcomputer; then, measure the piston and distance between pallet scales;

[0029] b. Place the spring to be tested upright on the pallet scale; the microcomputer sends a command to the stepping motor, and the stepping motor drives the piston to move downward according to the command, and the pallet scale starts to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com