Dynamic test method for gas intrusion resistance of oil and gas well working fluid

A technology of dynamic testing and working fluid, which is applied in the field of experimental research and testing, can solve problems such as increased safety risks, no test method for anti-air intrusion ability, etc., and achieve the effect of enhancing applicability, reducing maintenance cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

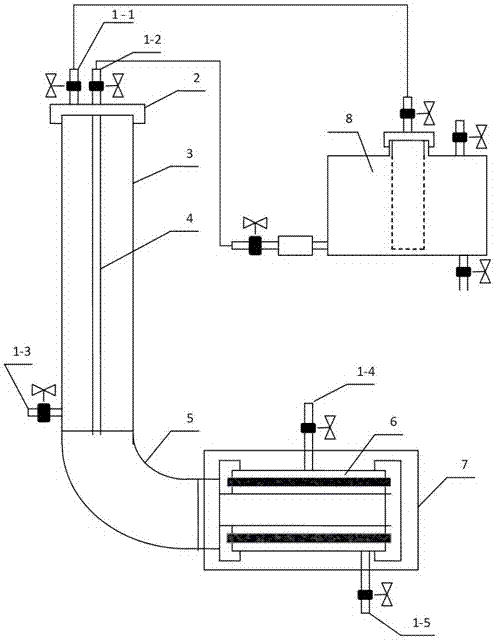

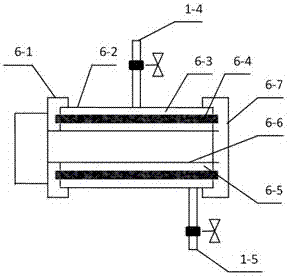

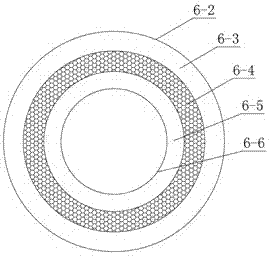

[0031] like Figure 2 to Figure 5 As shown, the dynamic test method of oil and gas well working fluid anti-gas invasion ability according to the present invention adopts a multifunctional oil and gas well working fluid performance testing device, and the testing device includes an outer pipe 3, a central pipe 4, a simulated well bottom 6, and a temperature control device 7. Circulation filter device 8. Both the outer pipe 3 and the central pipe 4 are transparent and visible pressure-bearing pipe strings, so that it is convenient to observe the fluid condition in the pipe. The outer tube 3 is also provided with a height scale line, which is convenient fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com