Plasma treatment device

A plasma and processing device technology, applied in the field of plasma processing, can solve problems such as high temperature, uncontrollable temperature, and affecting the etching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention discloses a plasma processing device. In order to make the above objects, features and advantages of the present invention more obvious and easy to understand, the specific implementation of the present invention will be described in detail below with reference to the drawings and examples.

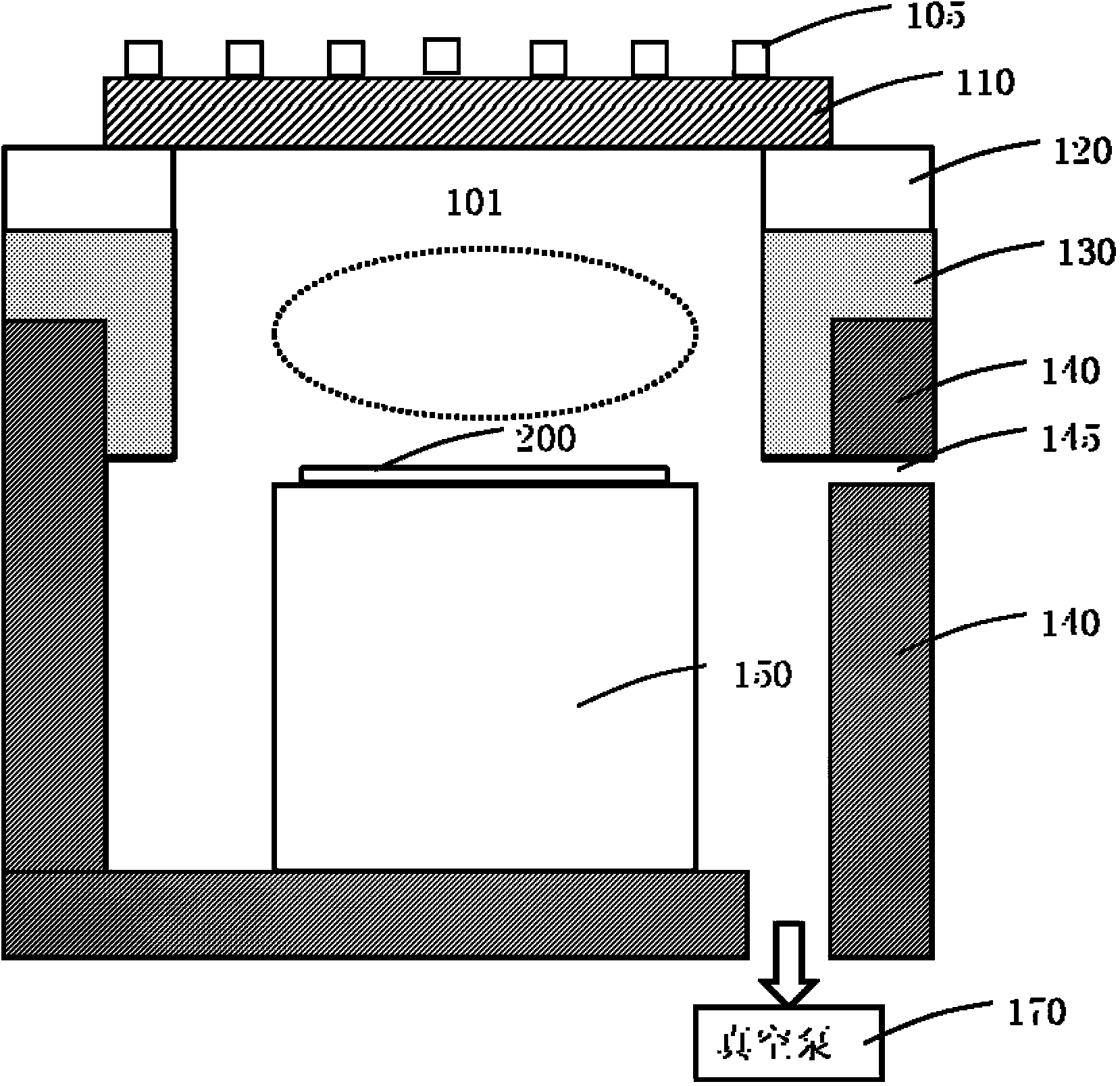

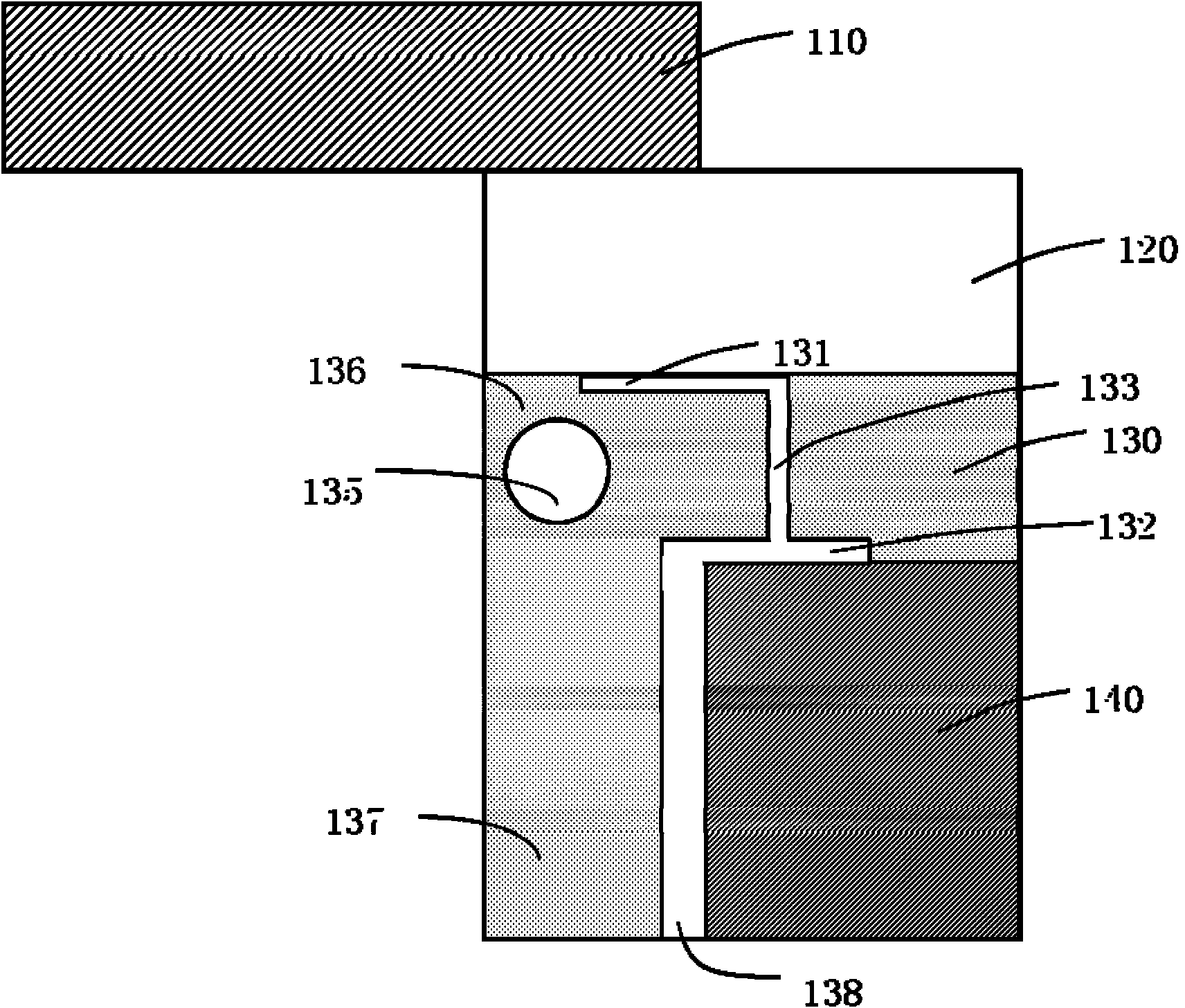

[0020] figure 1 It shows a schematic structural diagram of a plasma processing device disclosed in the present invention, especially relates to an inductively coupled plasma processing device, the plasma processing device includes a chamber shell 100 and a reaction chamber 101, and a base 150 is arranged in the reaction chamber 101 Used to support the substrate 200. The cavity shell includes an insulating window 110, and an inductance coil 105 is arranged above the insulating window 115. The inductance coil 105 generates a strong high-frequency alternating magnetic field under the action of a radio frequency power source (not shown in the figure), so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com