Full-automatic material breaking and receiving device and production process thereof

A production process, fully automatic technology, applied in the direction of thin material processing, transportation and packaging, winding strips, etc., can solve the problems of high production intensity and low efficiency, and achieve the effect of effective and fast cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

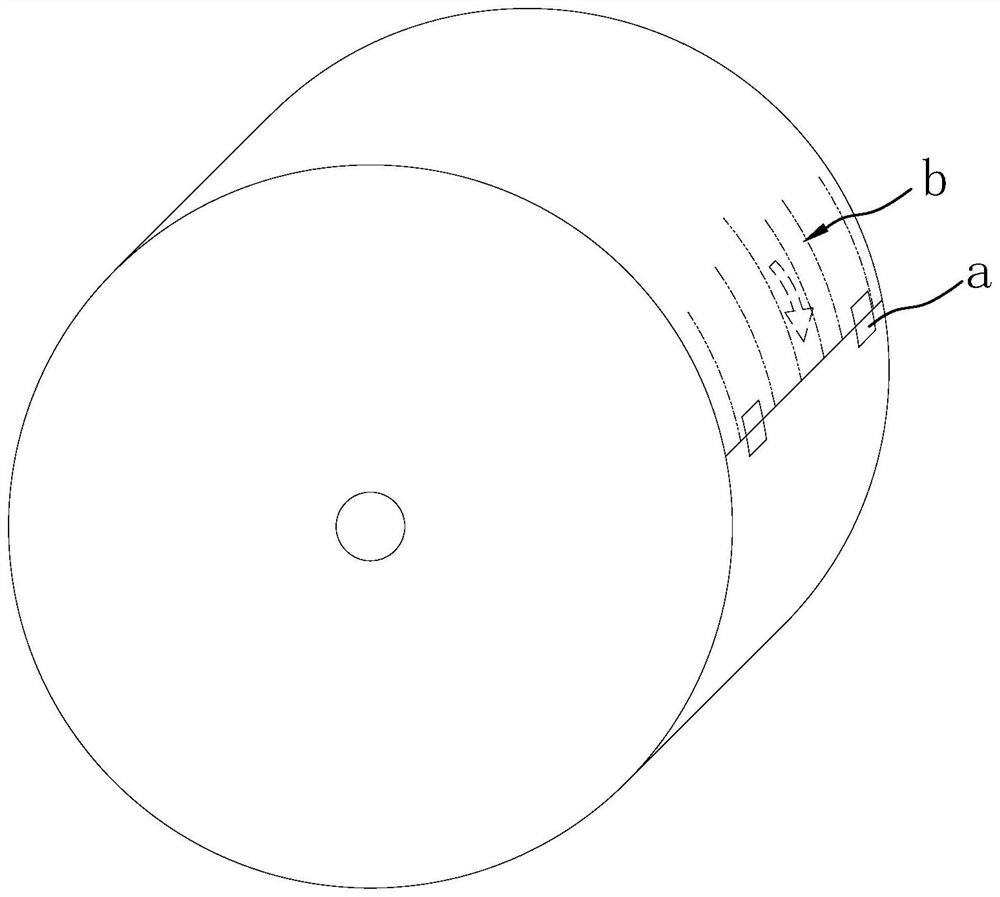

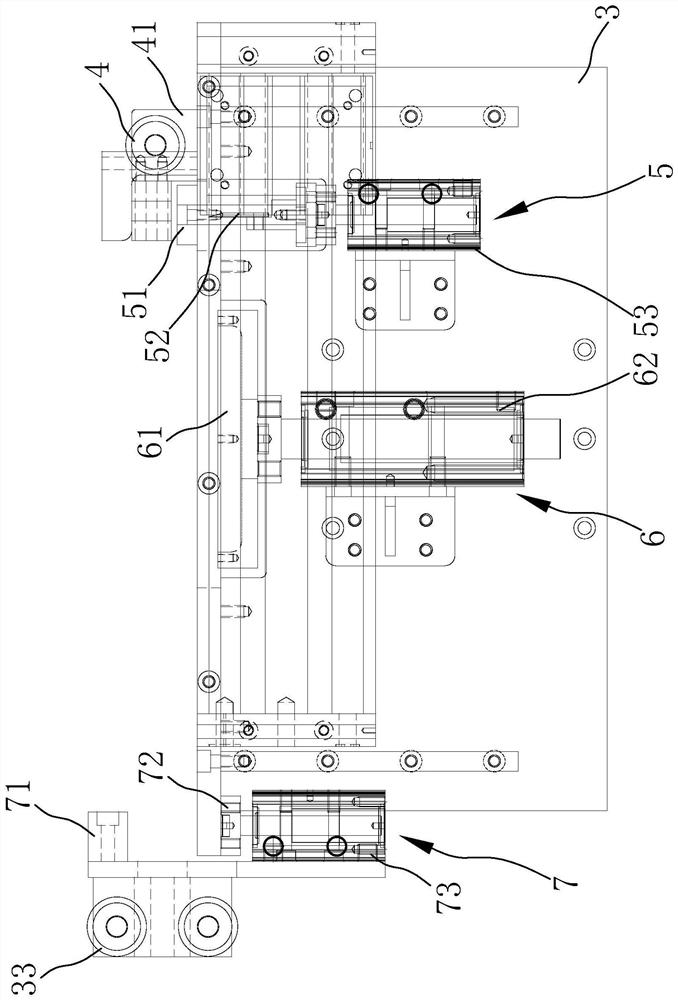

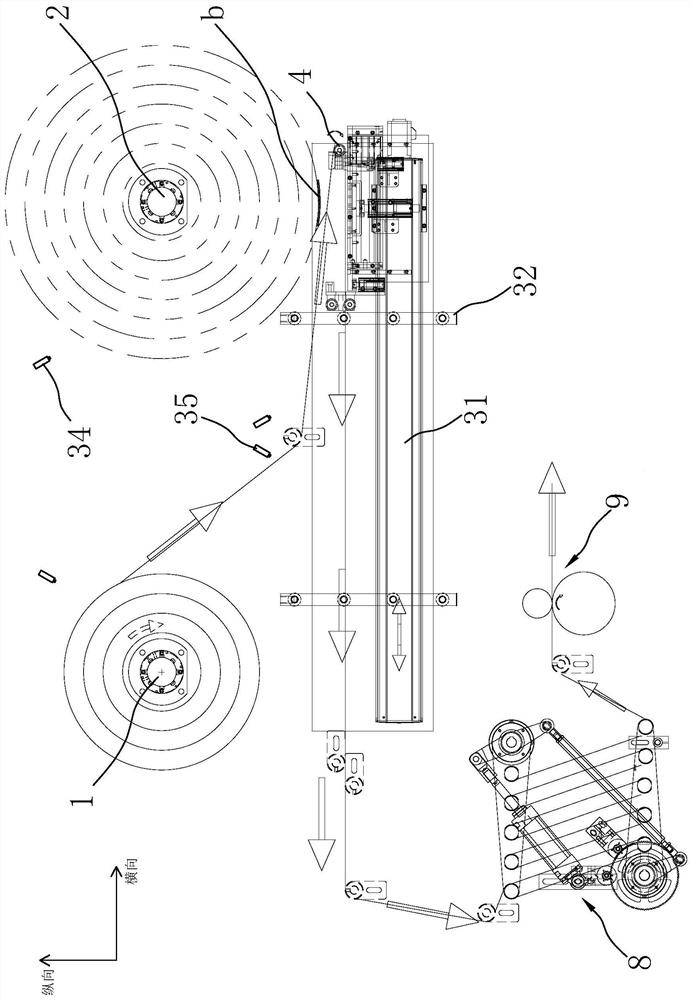

[0056] refer to Figure 1 to Figure 8 , a fully automatic material breaking device, including a frame, a number of guide rollers for material guidance and a control system for the overall control of the device, the frame is provided with two symmetrically distributed left unwinding rollers 1, right Unwinding roller 2, the left unwinding roller 1 and right unwinding roller 2 are all servo-driven; both the left unwinding roller 1 and the right unwinding roller 2 are designed as independent central unwinding drives to ensure automatic switching. During the process, the left and right rolls of material can be independently controlled and moved, and the remaining part is automatically rewound after the material change is completed;

[0057] Define the center connection direction of the left unwinding roller 1 and the right unwinding roller 2 as the horizontal direction, and the vertical direction is the vertical direction;

[0058] The frame is provided with a traverse bracket 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com