Electrostatic Discharge Protection Structure

An electrostatic discharge protection, conductive type technology, applied in the field of electrostatic discharge protection structures, can solve problems such as uneven conduction of components, and achieve the effect of improving soundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

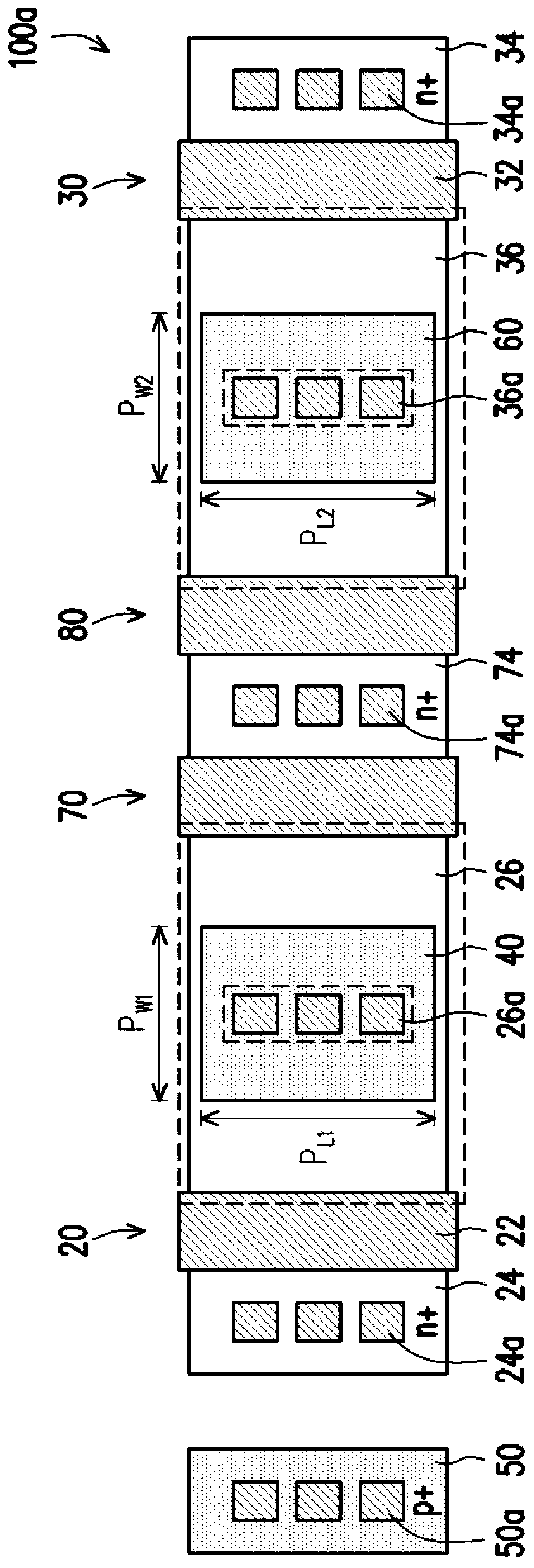

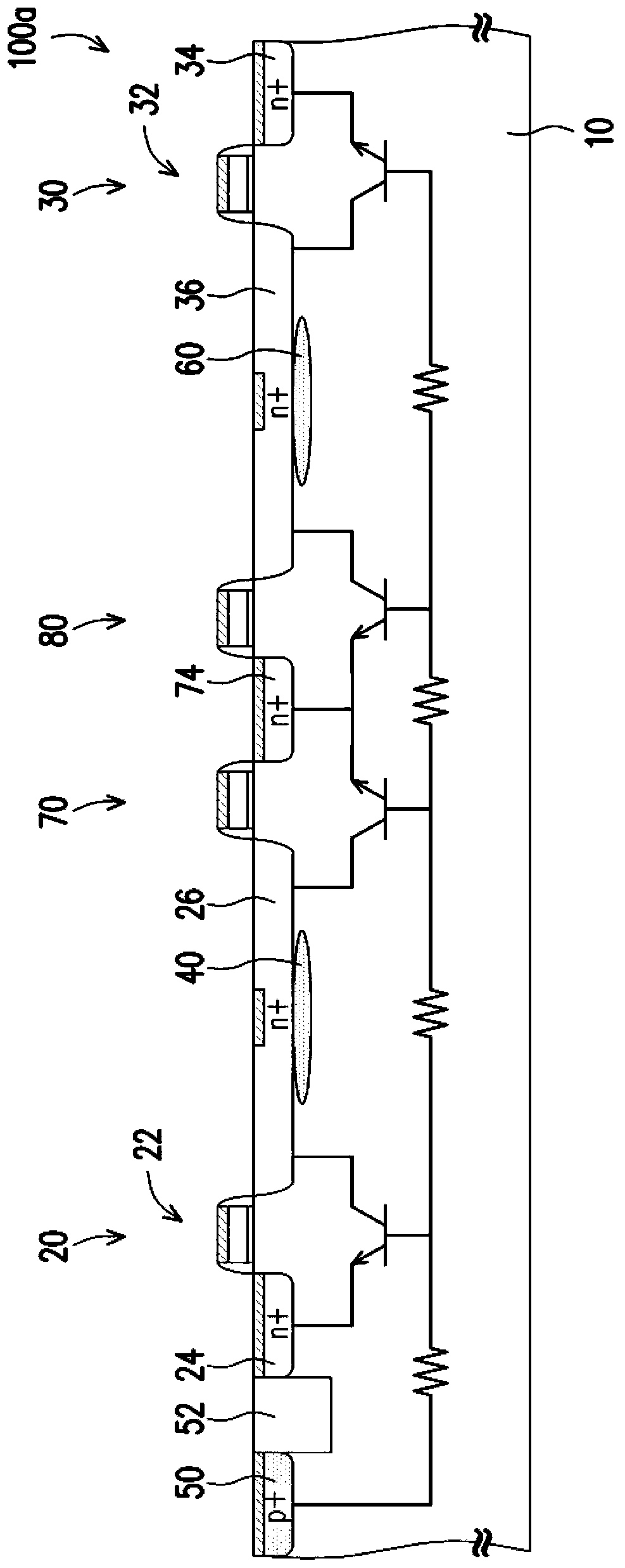

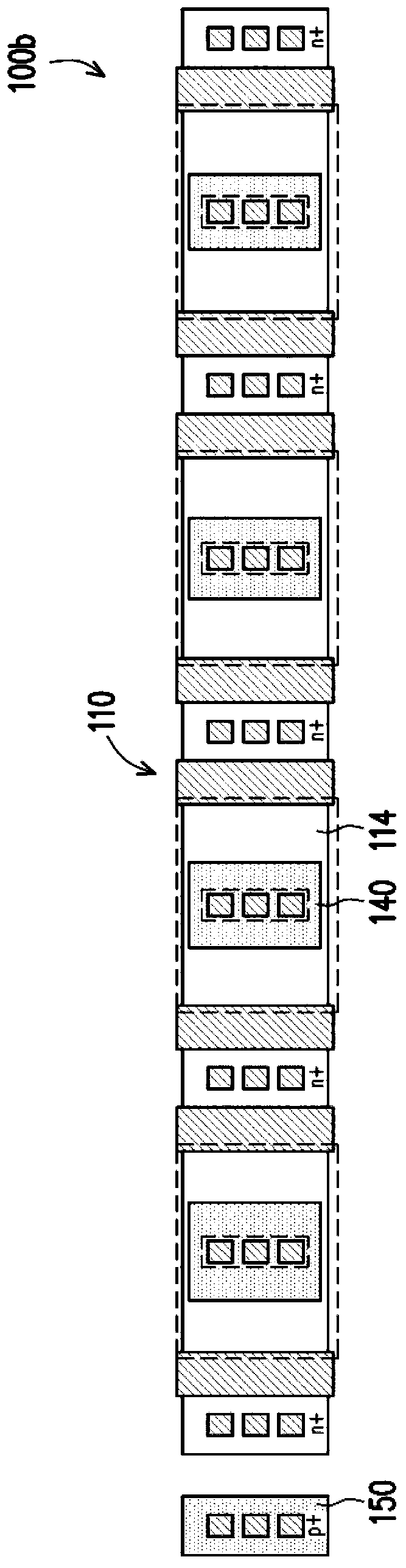

[0052] An electrostatic discharge protection structure according to an embodiment of the present invention includes a plurality of metal oxide semiconductor elements. Under the drain region of each metal oxide semiconductor device, a doped region having a conductivity type different from that of the drain region is provided to improve the soundness of the electrostatic discharge protection structure. Furthermore, the area / doping concentration of the doped region below the drain region close to the pickup region is greater than the area / doping concentration of the doped region below the drain region far away from the pickup region, so that each parasitic BJT The breakdown voltage of each is roughly the same, which in turn makes the turn-on time of each parasitic BJT almost the same.

[0053] figure 1 It is a partial plan view of the electrostatic discharge protection structure of the embodiment of the present invention. figure 2 is a partial cross-sectional schematic diagram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com